-32- G7209/10 14'' Table Saw

SECTION 7: MAINTENANCE

V-Belt

To ensure optimum power transmission from the

motor to the blade, the V-belts must be in good

condition and operate under proper tension.

When replacing V-belts, it is important to replace

all four at the same time - even if they do not all

appear worn.

Belt tension should be checked at least every 3

months; more often if using the table saw inten-

sively.

The V-belts are accessed through the cavity on

the right side of the saw. They link the arbor and

motor pulleys. To check V-belt tension:

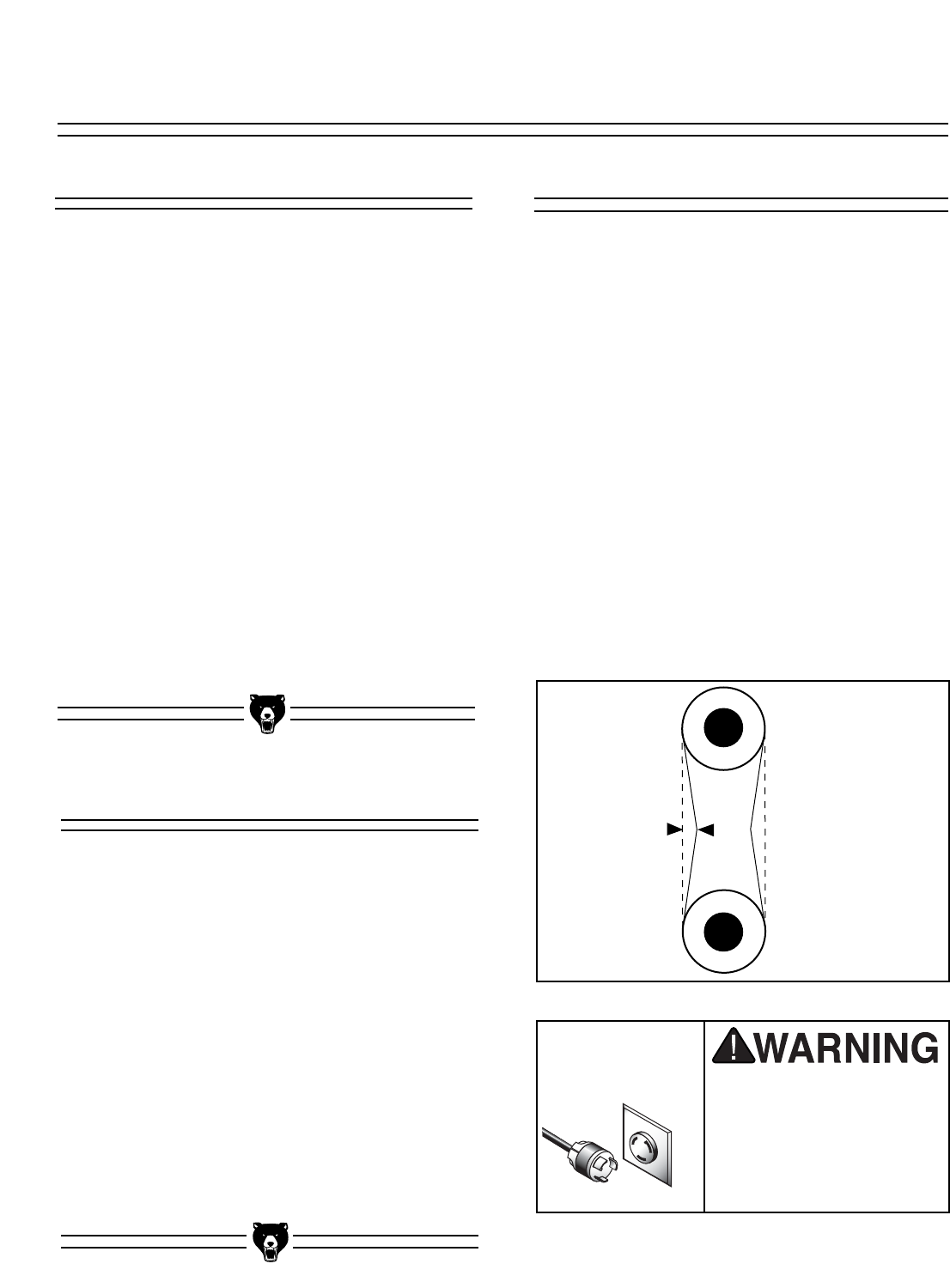

1. Squeeze the center of each V-belt.

2. Note the amount of deflection. Deflection

should be approximately

3

⁄4". See Figure 42.

Figure 42.

Table

The nonpainted surfaces on the Model G7209/10

should be protected against rust and pitting.

Wiping the machine clean after every use ensures

that wood dust isn’t allowed to trap moisture

against bare metal surfaces.

Some woodworkers recommend using automo-

tive paste wax on exposed steel and cast iron sur-

faces. The wax provides a layer of protection, as

well as reducing friction between lumber and the

table, making cuts faster and smoother. Avoid

waxes that contain silicone or other synthetic

ingredients. These materials can find their way

into lumber that’s being worked, and can make

staining and finishing difficult. If you use paste

wax, make sure that it’s 100% Carnauba wax.

Regular periodic maintenance on your Model

G7209/10 will ensure its optimum performance.

Make a habit of inspecting your machine each

time you use it. Check for the following conditions

and repair or replace when necessary:

1. Loose mounting bolts.

2. Worn switch.

3. Worn or damaged cords and plugs.

4. Damaged V-belt.

5. Any other condition that could hamper the

safe operation of this machine.

6. Inspect blades for damage.

7. Guard alignment and operation.

General

Disconnect power to the

machine when perform-

ing any maintenance or

repairs. Failure to do this

may result in serious

personal injury.

!

3

⁄4"