G8749 Drum/Flap Sander -11-

Operating this equipment has the potential

to propel debris into the air which can

cause eye injury. Always wear safety glass-

es or goggles when operating equipment.

Everyday glasses or reading glasses only

have impact resistant lenses, they are not

safety glasses. Be certain the safety glass-

es you wear meet the appropriate stan-

dards of the American National Standards

Institute (ANSI).

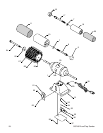

Drum Sanding

Drum sanding is perfect for performing sanding

operations on edge contours. Inflate the drum to

the desired air pressure using a hand pump. Use

a soft sleeve and lower pressure when sanding

contours with rounded or soft edges. A hard

sleeve and higher pressure is desirable when the

edge is to be sharp. Be certain to mount the abra-

sive sleeve on the drum so the direction of rota-

tion of the sleeve will match the spindle rotation of

the machine you are using.

Figure 7 shows a typical sanding operation.

Remember when sanding, the spindle is rotating

towards the operator.

Figure 8. Typical drum sanding.

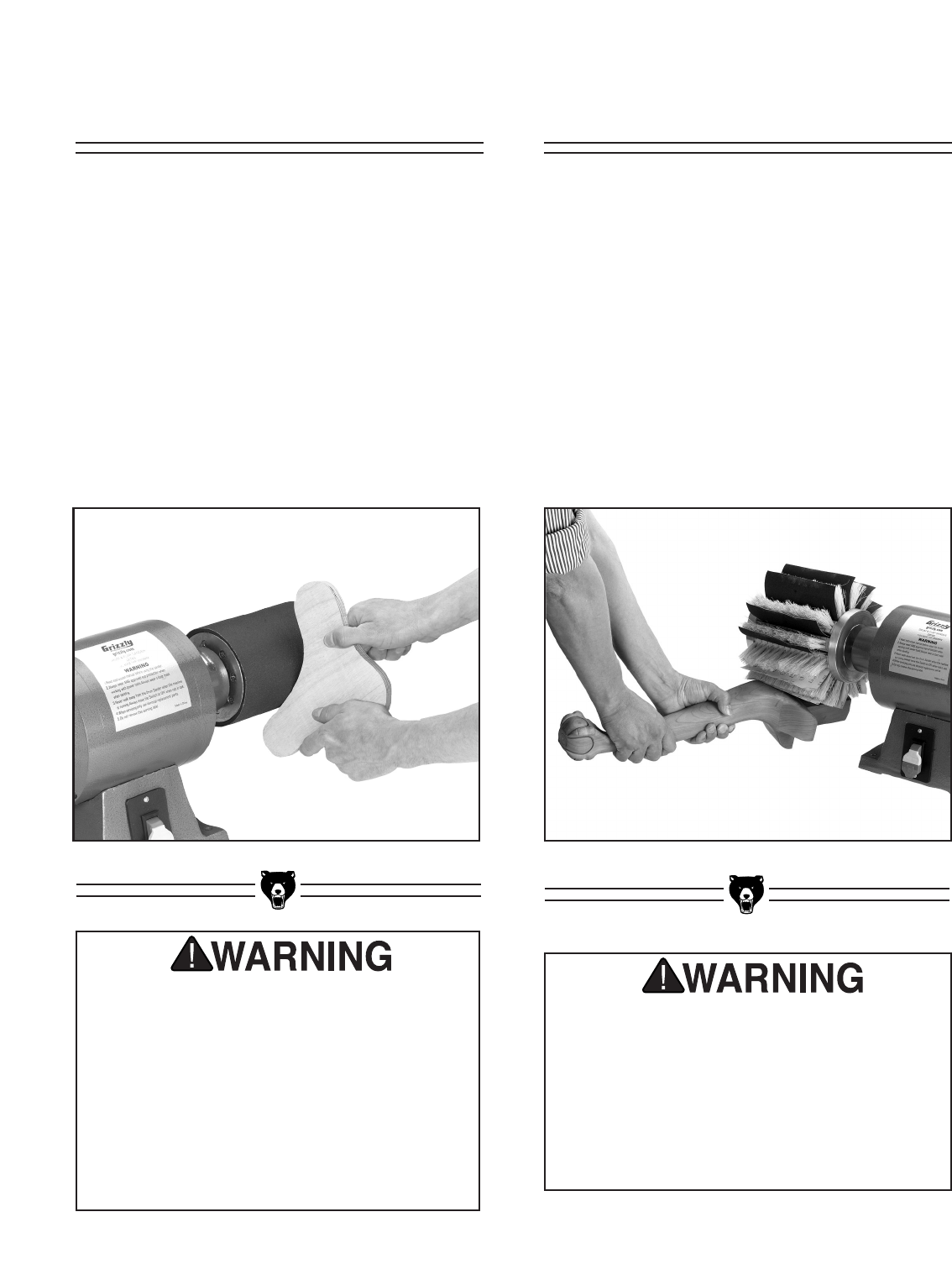

Flap Sanding

Flap sanding is useful for sanding rounded or

spherical shapes. With the flap sander mounted

on the left hand spindle, the abrasive side of the

individual sanding flaps will be rotating toward the

operator. It is generally best to introduce the

workpiece to the downward side of that rotation

for the best control of the sanding forces.

Figure

9

shows a typical sanding operation.

The flap sander is supplied with 120 grit paper

installed. The abrasive sheets can be replaced

with different grits if needed. See the

Maintenance section for detail on replacing the

sandpaper.

Figure 9.Typical flap sanding.

DO NOT attempt to operate this machine

before completing the assembly and adjust-

ment instructions. Be sure that the switch is

off and the cord is disconnected from the

power source at all times until assembly and

adjustment are complete and you have

reviewed all safety guidelines. Serious

injury could occur.