-14- G8793 12" Double Disc Sander

Operating this equipment has the potential

to propel debris into the air which can

cause eye injury. Always wear safety glass-

es or goggles when operating equipment.

Everyday glasses or reading glasses only

have impact resistant lenses, they are not

safety glasses. Be certain the safety glass-

es you wear meet the appropriate stan-

dards of the American National Standards

Institute (ANSI).

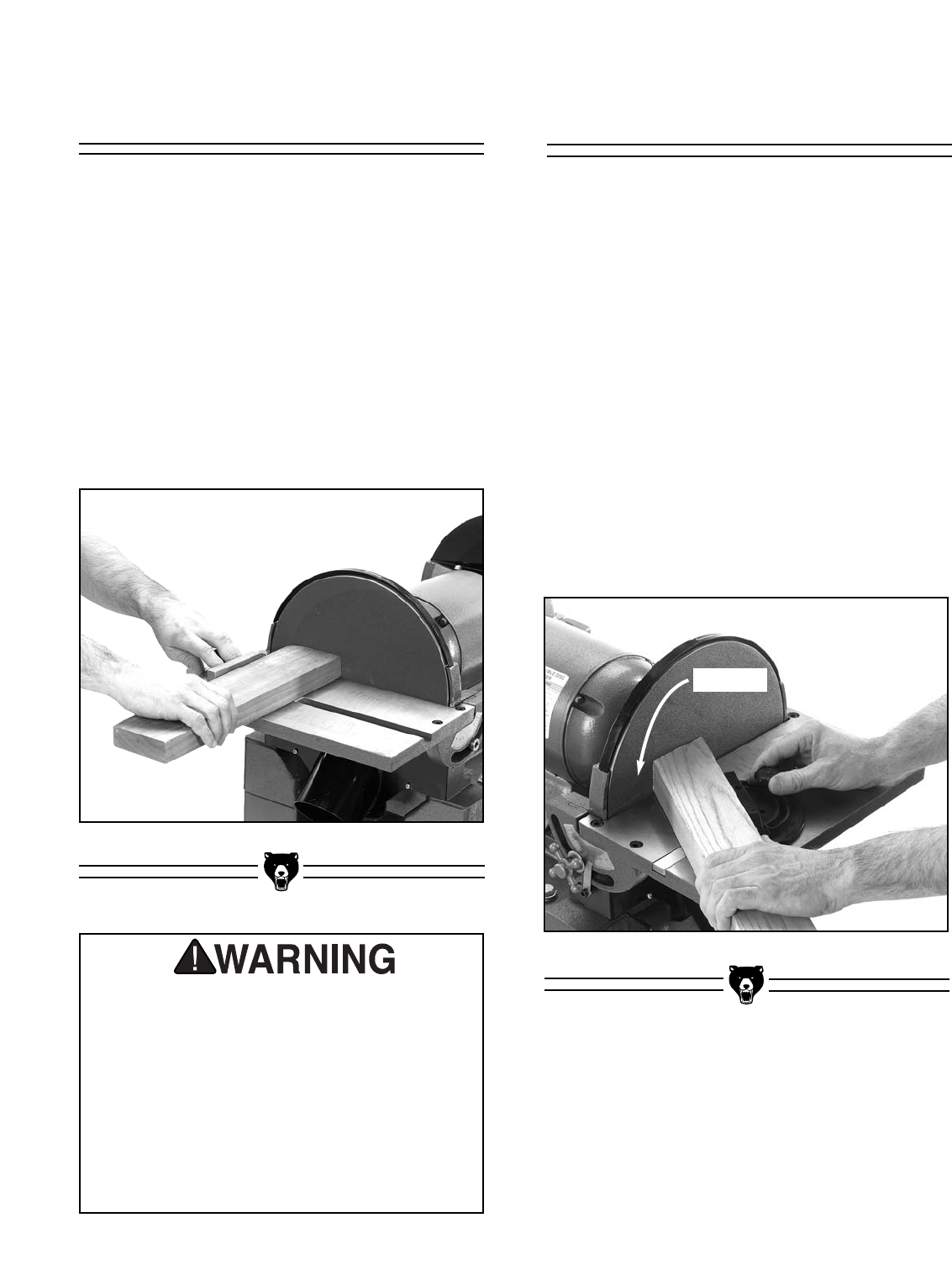

Disc Sanding

First, set the angle of the table relative to the

sanding disc. When perpendicularity is required

between two surfaces, the miter gauge will help

to guide the workpiece so that the relationship is

maintained. Place one surface firmly against the

face of the miter gauge, with the other surface

against the face of the disc. See Figure 8. If

sanding curves or irregular shapes, freehand

sanding without the miter gauge can be done.

Always keep the workpiece on the side of the

wheel which is rotating down toward the table.

This will keep the workpiece from flying out of

your hands from the rotational forces.

Figure 8. Disc sanding.

Miter Sanding

The most efficient way to get a perfect miter is to

cut the workpiece slightly long and sand it to the

desired dimension. Miter sanding can be done

easily with the miter gauge:

1. Loosen the knob on the miter gauge and

adjust the angle to the desired point.

Tighten the knob.

2. Slide the miter gauge into its slot and use it

to hold your workpiece in position. The

miter gauge can be used in either direction

in the slot to achieve the proper relation of

the workpiece to the disc.

3. With light, but firm pressure, push the work-

piece slowly into the downspin side of the

rotating disc. See Figure 9.

Figure 9. Mitering with gauge reversed.

Rotation