G9717 6" Grinder

-9-

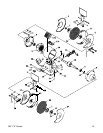

WWhheeeell MMoouunnttiinngg

Before mounting any wheel, check it for integrity

by performing a “ring check”. Balance the wheel

on one finger, then lightly tap the rim of the wheel

with a piece of wood such as the handle of a

hammer. The wheel should have a ringing or

harmonic type of sound. If it responds with a dull

thud it may indicate that the wheel has cracks. Do

not use a wheel which is suspected of having

cracks, or if there are visual chips, nicks or dents

in the wheel surface. These discontinuities can

lead to wheel failure where the wheel flies apart

at operating speed. Always be sure to use a

wheel which is rated for operating at speeds

equal to or greater than 3450 RPM.

The wheel guard assembly must be removed in

order to mount or dismount a grinding wheel.

11

. Remove the three Phillips

®

head screws

and nuts which go through the outer guard.

22..

Remove the outer guard and rim guard.

SSeeee FFiigguurree 44..

FFiigguurree 44..

Wheel guard components.

FFiigguurree 55..

Grinding wheel assembly.

NNEEVVEERR aasssseemmbbllee aa ggrriinnddiinngg wwhheeeell oonn tthhee

aarrbboorr wwiitthhoouutt ppaappeerr oorr ffiibbeerr ddiissccss bbeettwweeeenn tthhee

wwhheeeell aanndd tthhee ffllaannggee.. OOmmiittttiinngg tthhee ddiissccss ccaann

ppuutt uunndduuee ssttrreessss oonn tthhee wwhheeeell ccaauussiinngg iitt ttoo

ccrraacckk aanndd ppoossssiibbllyy ffllyy aappaarrtt.. AALLWWAAYYSS ““rriinngg

cchheecckk”” aa wwhheeeell bbeeffoorree aasssseemmbbllyy ttoo mmaakkee cceerr--

ttaaiinn iitt iiss ssoouunndd wwiitthh nnoo ccrraacckkss oorr ffllaawwss..

33..

Use a

3

⁄4" or 19mm open end wrench on the

nut which holds the wheel on the arbor.

Hold the wheel from turning with the other

hand. Note that the wheel on the left hand

side of the machine is a left hand thread, so

loosening it will require turning it clockwise.

44

. Remove the outer wheel flange and the

paper disc.

55..

Pull the wheel free from the arbor. There

will also be a paper disc and a wheel flange

on the back side of the wheel. Always make

certain there is a paper or fiber disc

between the wheel flanges and the wheel

itself, this helps to spread the rotational

forces across the inner area of the wheel.

SSeeee FFiigguurree 55..

66..

Mount the new wheel in the reverse order.

First a wheel flange, a paper disc, the

wheel, a paper disc, a wheel flange and

finally the nut itself. Tighten the nut snugly

but do not over tighten. Over tightening can

crack the wheel.

77..

Run a new wheel for at least 1-2 minutes

while standing clear of the line of rotation.

If a wheel does have defects it will gener-

ally fail as soon as it gets up to full speed

.