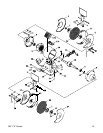

G9717 6" Grinder

-10-

SSEECCTTIIOONN 66:: MMAAIINNTTEENNAANNCCEE

Make a habit of inspecting your Grinder each

time you use it. Check for the following conditions

and repair or replace when necessary:

11..

Loose mounting bolts.

22..

Worn switch.

33..

Worn or damaged cords and plugs.

44..

Damaged Grinding Wheel.

55..

Any other condition that could hamper the

safe operation of this machine.

GGeenneerraall

GGrriinnddiinngg WWhheeeellss

The grinding wheel should be inspected before

every use. Use the ring check method noted in

the Grinding Wheel section in Operations to ver-

ify the structural integrity. If using coolant during

grinding, always run the wheel for 5-10 minutes

at the end of the operation to remove any coolant

from the wheel. Take care in storing grinding

wheels to keep them free from potential damage

by being dropped, or having other items drop on

them.

Replace the wheel when the wheel diameter is

reduced to 4". Operating at anything less than

this diameter does not allow the proper alignment

of the Tool Rest and the Eye Shield.

Depending on the type of grinding you do, the

grinding wheel may require periodic dressing.

There are several different types of wheel dress-

ing devices available on the market. Use a suit-

able diamond or silicon carbide stick type dress-

er. Sweep it smoothly and evenly several times

across the face of the wheel. Dressing restores

the abrasive quality of the wheel surface, plus it

will bring the wheel edge back to a square form.

Refer to the instructions which accompany your

dressing accessory for complete detail on wheel

dressing.

LLuubbrriiccaattiioonn

The Model G9717 features factory-sealed bear-

ings. A sealed bearing requires no lubrication

during its lifetime. Should a bearing fail, your

grinder will probably develop a noticeable rumble,

which will increase when the machine is put

under load. If the bad bearing is not replaced, it

will eventually seize - possibly doing damage to

other parts of the machine. Bearings are standard

sizes and can be replaced through Grizzly.