Ultimate Series Jointers -15-

Knife Setting

Gauge

Gib

Gib Bolt

Jack Screw

Knife

Outfeed Table

4. Adjust the screws below each end of the

knife until both feet of the gauge rest flush

and evenly on the outfeed table and the knife

edge is just touching the bottom of the gauge.

Securely tighten each gib bolt. The gauge will

set the knives at a uniform protrusion above

the cutterhead. The knife height should vary

no more than .002"-.003" across the length of

the cutterhead. A dial indicator can be used

to check variation in thousandths of an inch;

however, the standard knife setting gauge is

satisfactory for reasonably accurate knife set-

ting tasks.

5. Repeat the same procedure on the remaining

knives.

The knives are locked into the cutterhead with

wedge-type gibs and gib bolts. Jack screws under

the knives allow fine tuning to help in the setting

process. To re-align the knives:

1. Unplug the jointer!

2. Loosen the gib bolts until the knife is loose in

the slot. The gib bolts turn clockwise to

loosen and counterclockwise to tighten

(when facing the head of the bolt). See

Figures 10 and 11.

3. Place the knife setting gauge across the knife

edge and the outfeed table as described pre-

viously.

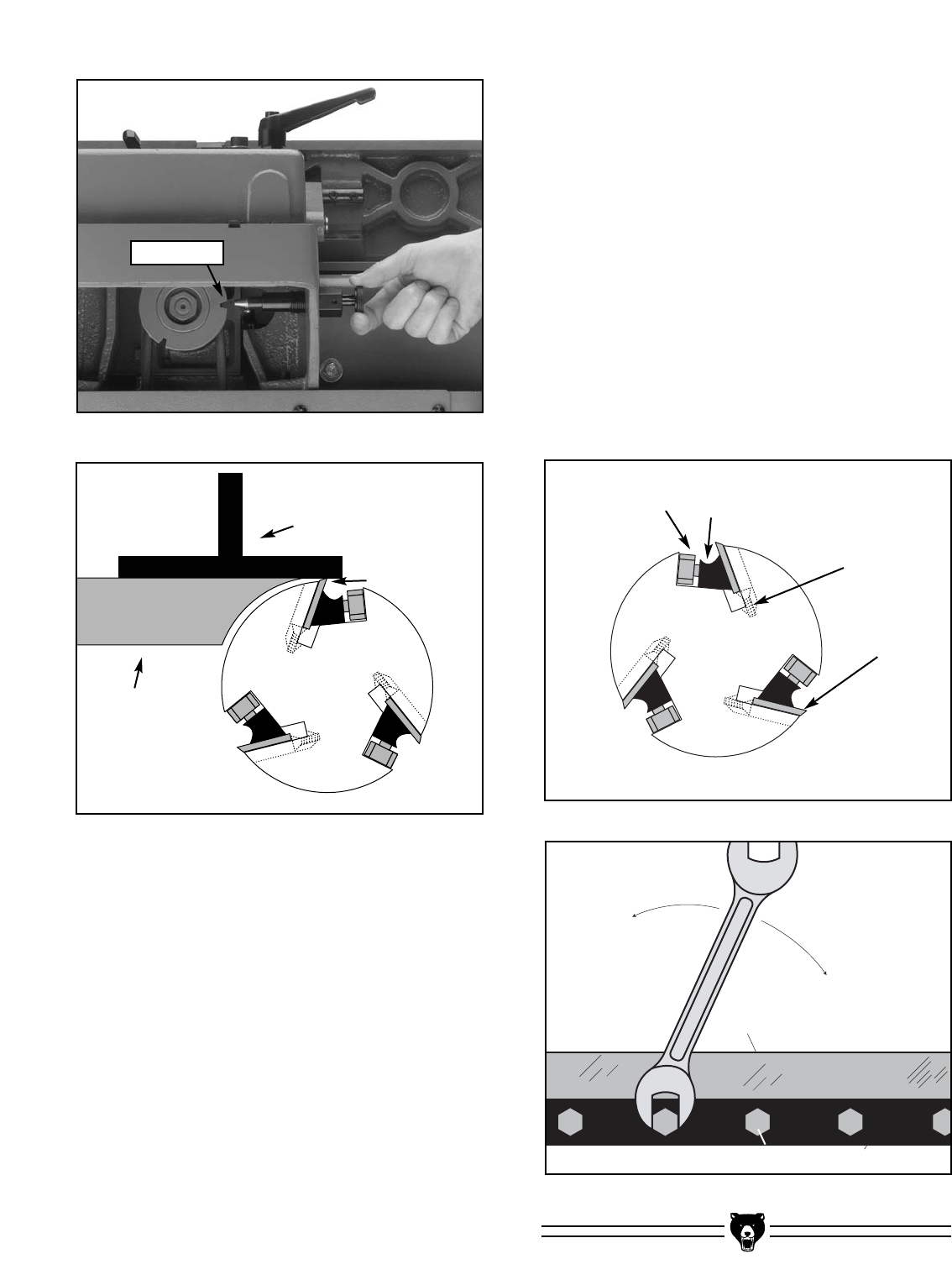

Figure 9 shows the setting of the knives with the

knife setting gauge.

Figure 10. Parts of the cutterhead.

Figure 11. Tightening the gib bolts.

Knife

Gib

Gib Bolt

Loosen

Tighten

Figure 8. Engaging the brake rod.

Knife Edge At

Highest Point

of Rotation

Brake Rod