Extreme Duty Planers -15-

Table Rollers

The height of the table rollers will vary, depending

on the type of material you intend to plane. When

planing rough stock, you will need to set the roll

-

ers high to keep the lumber from dragging along

the table. Milled lumber should be planed with the

rollers set lower.

To adjust the table rollers correctly:

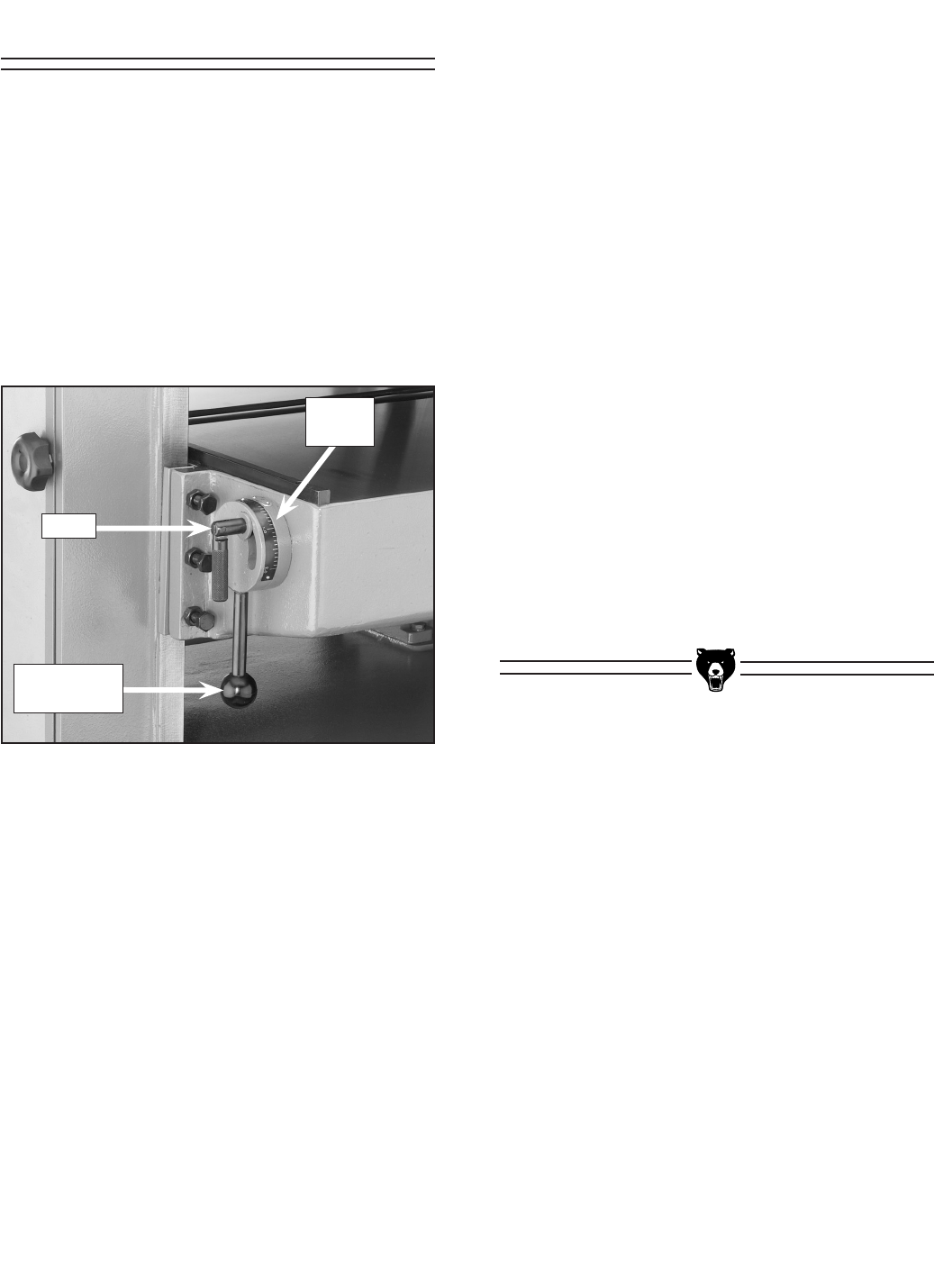

1. Loosen the lock on the adjustment lever

shown in Figure 17. Pull the lever up to raise

the table rollers.

Figure 17. Roller height adjustment controls.

Lock

Height

Scale

Adjustment

Lever

2. Determine the appropriate height for the type

of stock you are using.

The scale at the base of the adjustment lever

is numbered “0”, “1” and “2”. These numbers

represent how many millimeters the top

of the rollers are above the surface of the

table.

Since 1mm = .03937", figure that each notch

on the scale is approximately .004". The

ideal tolerance for the height of the table roll

-

ers is between .002"-.016".

Note—If the table rollers are too high, snipe

or chipping may occur at the ends of the

workpiece. Only use the higher settings for

rough cut lumber. If you are unsure about

which height to use, experiment on scrap

lumber by using the trial and error method.

Always start at the smaller tolerances and

work up.

3. Pull the adjustment lever up to the appro-

priate scale marks. Secure the adjustment

lever by tightening the lock.