Extreme Duty Planers -25-

NOTICE

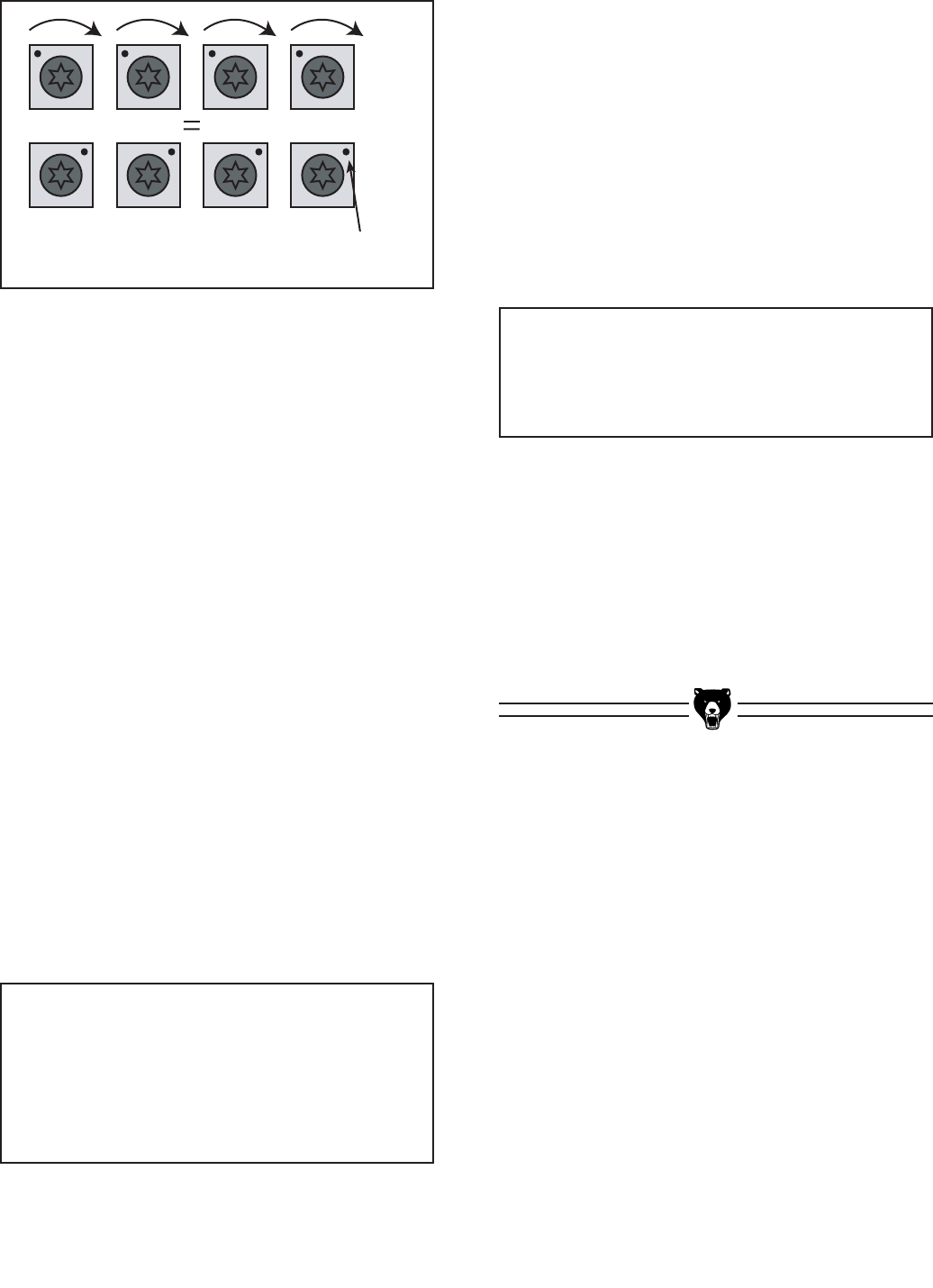

Always rotate each insert in the same direc-

tion. When an insert returns to the original

position, it is time for replacement.

Figure 10. Always rotate carbide cutters in the

same direction to keep track of the dull or

damaged edges.

Reference Dot

NOTICE

Remove sawdust from the heads of the

Torx

®

screws before attempting to remove

them from the cutterhead. The head of the

Torx

®

screws could become stripped if this

is not done.

To install/adjust the carbide cutters:

1. Disconnect the planer from the power

source!

2. Open the top cover door to gain access to the

cutterhead, and open the left-hand service

door to gain access to the cutterhead pulley,

so you can safely rotate the cutterhead.

3. Prepare the air wrench (included with your

planer) by installing a T-20 Torx

®

bit, con-

necting it to an air compressor regulated to

30 PSI, and setting the air wrench dial to the

“2” setting.

Note—This low pressure (torque) setting will

reduce the chance of cross threading the

Torx

®

screw threads as well as correctly pre-

torque the screws before final tightening.

4. Clean out sawdust from the heads of the

Torx

®

screws that you will loosen.

5. Paying attention to the location of the refer-

ence dot, remove and replace/rotate one

cutter at a time, sparingly oil the threads of

the Torx

®

screw with a light machine oil, and

tighten the screw with the air wrench.

Note—Torx

®

screws that are difficult to

remove with the air wrench can be removed

with the supplied T-handle. Carefully insert

a Torx

®

bit into the hole on the side of the

“cheater bar.” This should allow you enough

leverage to loosen the Torx

®

screws.

6. After all the carbide cutters that you adjusted

have been rotated/replaced, adjust the air

compressor air pressure to 82 PSI and make

sure the air wrench is still at the “2” setting

on the dial (this final torque setting will be

the equivalent of 48-50 INCH pounds).

7. Now final tighten the Torx

®

screws.