OPERATIONS

-17-

Important issues regarding blade perfor-

mance:

• Scroll saw blades wear out and must be

replaced frequently. Typically a blade will

stay sharp anywhere from

1

⁄2 to 2 hours

depending on how the blade is used and

what type of material is being cut.

• Best cutting results will be achieved when

cutting material less than 1" thick.

• When cutting material thicker than 1", use a

very slow feed rate.

• Blades will become dull quickly whenever

making cuts in plywood, hardwoods, and

laminates.

• Exerting excessive side pressure on the

blade greatly increases the chance of blade

breakage.

Teeth Per Inch Width Thickness Strokes-Per-Minute Material Being Cut

10 0.110" 0.020" 1200-1600 General purpose blade for cutting hard

and soft woods between

3

⁄16" and 2".

Also good for plastics, paper, felt, and

bone.

15 0.110" 0.020" 600-1200 Good for cutting very thin wood and

plastic between

3

⁄32" and

1

⁄2".

18 0.095" 0.010" 400-600 Good for tight radius cutting in thin

hard and soft woods between

3

⁄32" and

1

⁄8". Also good for veneer, bone, ivory,

and plastics

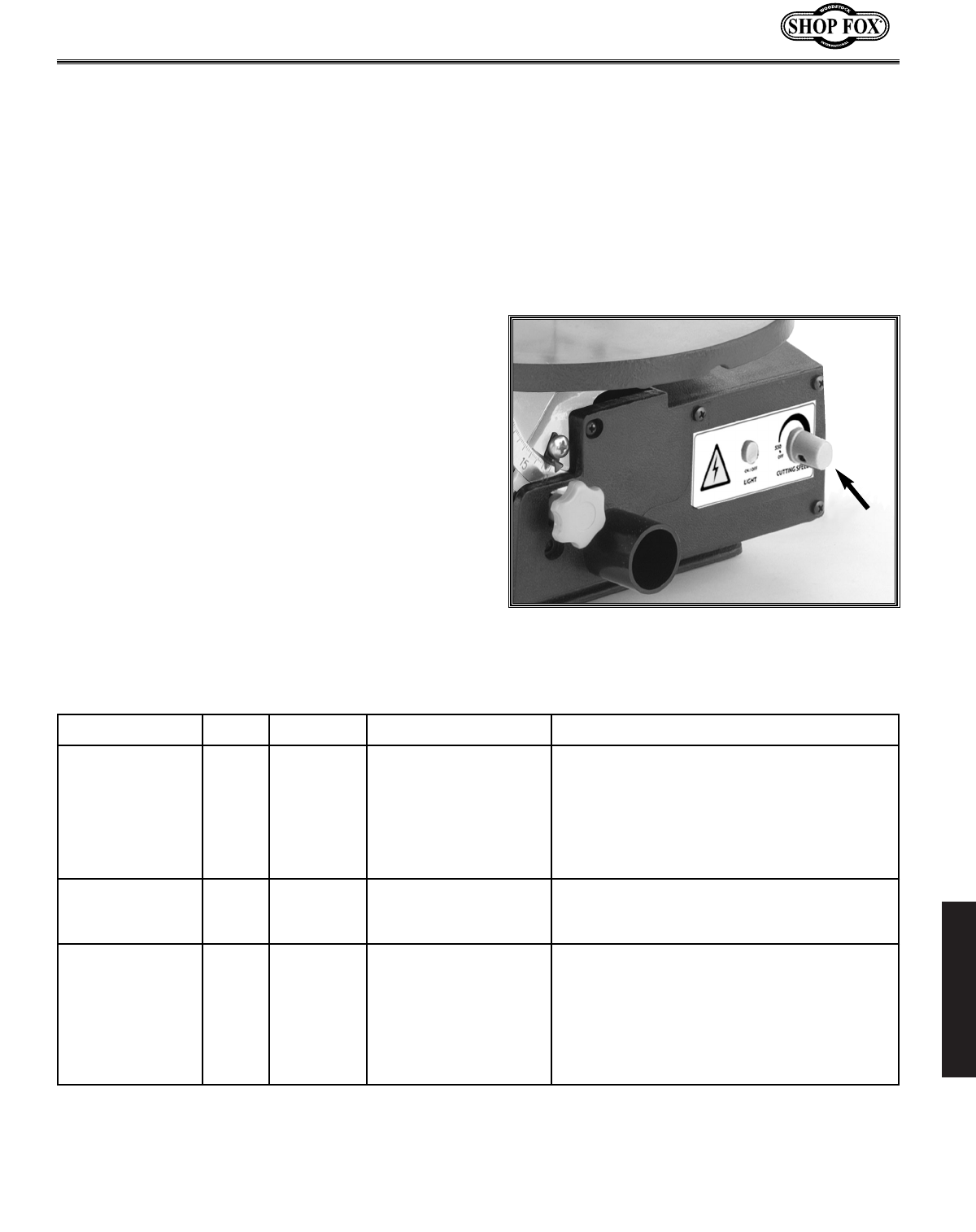

To change the blade speed:

The blade speed is variable between 400 and

1600 strokes-per-minute (SPM). Blade speed

adjustments are made using the variable speed

/power knob (Figure 11)on the front of the

scroll saw.

Figure 11. Variable speed/power knob.

Blade Selection Table

Blade SpeedBlade Information