SKU 66872 For technical questions, please call 1-800-444-3353. Page 13

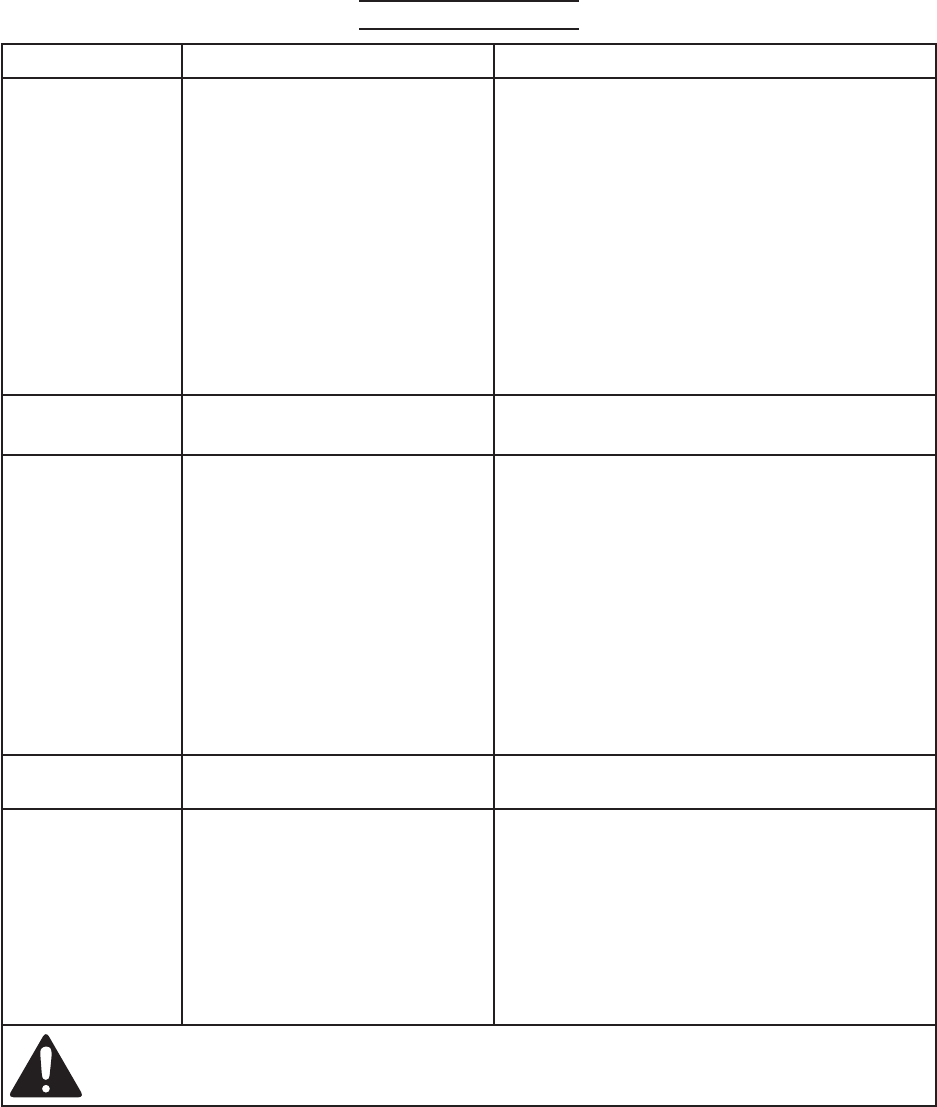

Troubleshooting

Problem Possible Causes Likely Solutions

Insufcient

fastener depth.

1. Incorrect tool depth setting.

2. Not enough air pressure.

3. Incorrect lubrication or not

enough lubrication.

4. Blocked air inlet screen (if

equipped).

5. Mechanism contaminated.

1. Adjust depth setting, if available.

2. Check for loose connections and make

sure that air supply is providing enough air

pressure (PSI) to the tool’s air inlet. Do not

exceed maximum air pressure.

3. Lubricate using air tool oil and grease

according to directions.

4. Clean air inlet screen of buildup.

5. Have qualied technician clean and lubricate

mechanism. Install in-line lter in air supply

as stated in Initial Set Up: Air Supply.

Fasteners drive

too deeply.

1. Incorrect tool depth setting.

2. Too much air pressure.

1. Adjust depth setting, if available.

2. Reduce air supply pressure (PSI).

Tool cycles

without ring

fastener.

1. Tool empty.

2. Incorrect fasteners used.

3. Magazine dirty or not

lubricated properly.

4. Insufcient air ow.

5. Nails jammed.

1. Fill with correct fasteners.

2. Empty, then ll with correct fasteners.

3. Clean and lubricate magazine and pusher.

4. Check for loose connections and make

sure that air supply is providing enough air

ow (CFM) and pressure (PSI) to the tool’s

air inlet. Do not exceed maximum air

pressure.

5. Check the Magazine, remove Nozzle, and

clear bent or broken nails.

Frequent

jamming.

Incorrect fastener type. Conrm fastener diameter, type, length, angle,

and collation type. Correct as needed.

Severe air

leakage.

(Slight air leakage

is normal,

especially on

older tools.)

1. Cross-threaded housing

components.

2. Loose housing.

3. Damaged valve or housing.

4. Dirty, worn or damaged valve.

1. Check for incorrect alignment and uneven

gaps. If cross-threaded, disassemble and

replace damaged parts before use.

2. Tighten housing assembly. If housing cannot

tighten properly, internal parts may be

misaligned.

3. Replace damaged components.

4. Clean or replace valve assembly.

Follow all safety precautions whenever diagnosing or servicing the tool.

Disconnect air supply before service.

out. Use a screwdriver to release

the jammed fastener by probing the

openings in the magazine.

3. Pull out the jammed fastener and the

remainder of the fastener strip that is

still in the magazine. Dispose of the

remaining fastener strip; it may be

bent or damaged in some other way.

4. If unable to clear jam using the meth-

od prescribed above, the tool should

be taken to a qualied service techni-

cian for proper servicing.