9

Figure 5. Drain Line

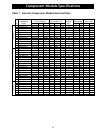

Refrigeration Piping

Suction Lines

NOTE: If the suction line must rise to the point higher than the suction connection on

the evaporator, a suction line trap at the outlet of the evaporator must be provided.

Horizontal suction lines should slope away from the evaporator toward the compressor at the rate of

1/4’ per 10 feet for good oil return. When multiple evaporators are connected in series using a common

suction line, the branch suction lines must enter the top of the common suction line.

Suction lines that are outside of refrigerated space must be insulated. See “Line Insulation” for more

information.

Suction Line Risers

NOTE: To provide proper oil return, a suction trap must be provided at the base of

all suction risers.

Prefabricated wrought copper traps are available, or a trap can be made by using two street ells and one

regular ell. The suction trap must be the same size as the suction line. For long vertical risers, additional

traps may be necessary. Generally, one trap is recommended for each length of pipe (approximately 20

feet) to insure proper oil movement. See Figure 4 below for methods of constructing proper suction line

P-traps.

Condensate Drain Lines

Copper drain lines should be used and properly protected from freezing. In running drain lines, provide

a minimum of 4 inches per foot pitch for proper drainage. Drain lines should be at least as large as

the evaporator drain connection. All plumbing connections should be made in accordance with local

plumbing codes. All condensate drain lines must be trapped, and run to an open drain. They must

never be connected directly to the sewer systems. Traps in the drain line must be located in a warm

ambient. We recommend a trap on all evaporators. Traps

located outside, or extensive outside runs of drain line

must be wrapped with a drain line heater. The heater

should be connected so that it is continuously on. It is

recommended that the drain line be insulated to prevent

heat loss. A heat input of 20 watts per lineal foot of

drain line for 0ºF (-18°C) room applications and 30 watts

per lineal foot for -20°F (-29°C) rooms is satisfactory.

Inspect the drain pan periodically to insure free drainage

of condensate. If the drain pan contains standing water,

check for proper installation. The drain pan should be

cleaned regularly with warm soapy water.

WARNING: All power must be disconnected

before cleaning. The drain pan also serves as

cover for hazardous moving parts. Operation

of unit without drain pan constitutes a hazard.

Figure 4. Suction P-traps

NOTE: Always trap drain lines individually

to prevent vapor migration.