H.E.R.O. INDUSTRIES LTD. 1000MD OWNERS MANUAL - “B” VERSION

23

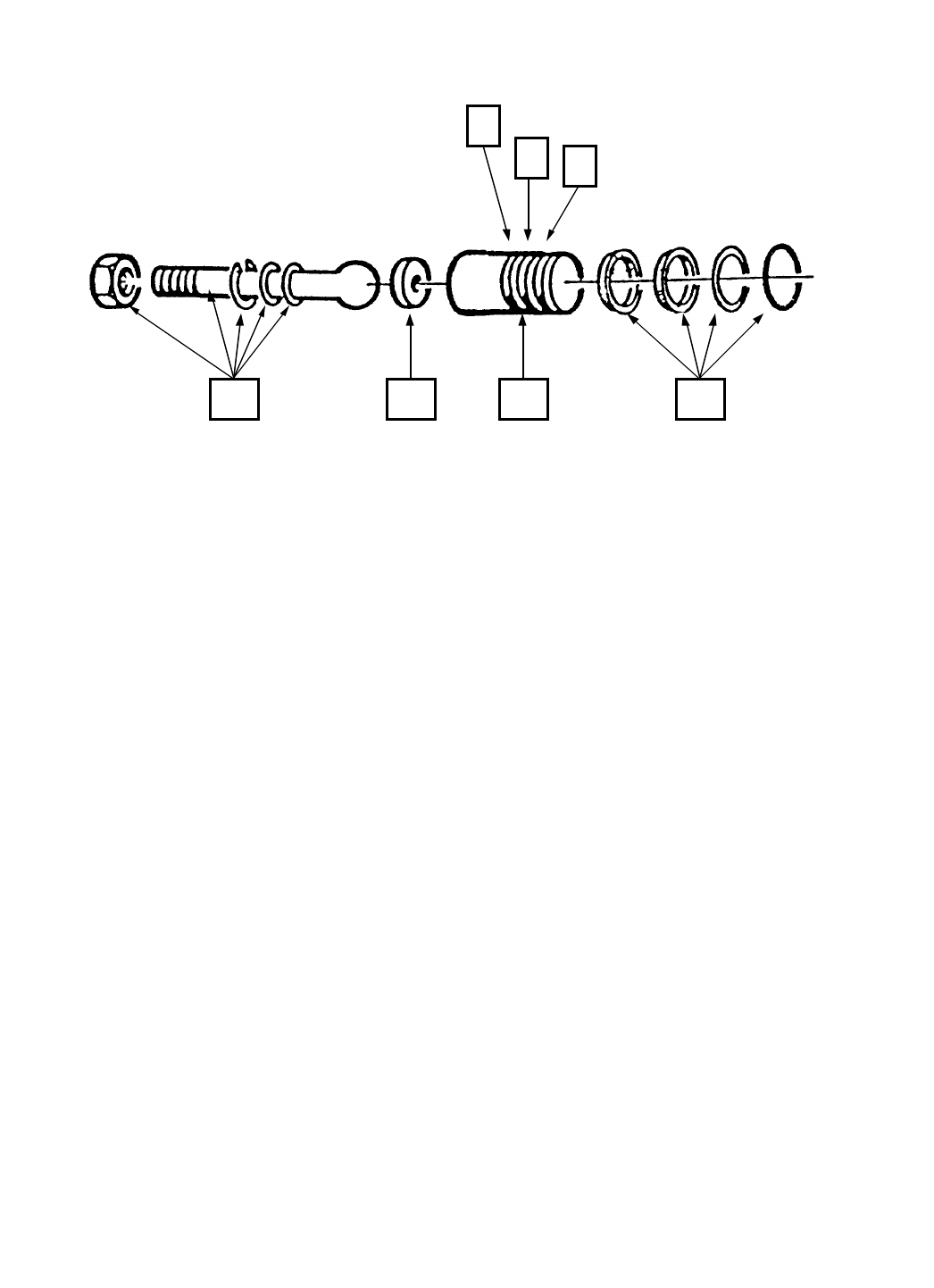

PISTON REPAIRS

(REF# 86)

TOOLS REQUIRED

-1/2" wrench

-11/16" wrench

-circlip pliers

-torque wrench

-grease

-vise grips

1. Remove hydraulic feed line, (ref# 60) from hydraulic intake valve, (ref# 59) and also remove hydraulic

return line, (ref# 69) from the pressure control valve, (ref# 70). Plug lines to minimize oil loss. (Hint;

golf tees work well for this)

2. Remove the bolts, (ref# 57) passing through the side frames, (ref# 106, 107), into the crossblock,

(ref# 56).

3. Place a drain tray under cylinder area.

4. Grasp the pump assembly, and pull away from the piston. Stop when piston pulls free, to allow the

hydraulic oil to drain into pan. Completely remove pump assembly from between side frames.

5. If only replacing piston seals, (ref# 87) continue at step 15.

6. Remove the piston, (ref# 86) from eccentric bearing, (ref# 95). Move to clean work bench for repairs.

7. Remove piston circlip, using circlip pliers. Remove piston from rod.

NOTE: Use extreme caution not to damage circlip or the internal circlip groove of piston.

NOTE: Piston rod circlip, washer, o-ring, and nut are not available individually. Parts are available

with the purchase of piston rod, (ref# 90) only.

NOTE: The circlip will have one sharp edge and one smooth edge. The smooth edge should be towards

the washer. If reversed, the rod will continually pull out of the piston.

8. Remove bronze piston rod seat, (ref# 89) from piston, (ref# 88).

9. Examine all parts for wear or damage. Replace as required.

10. Fill the center cavity of piston rod seat until flush with grease. Slide seat into piston with concave side

(filled with grease) facing out.

11. Lightly grease the ball end of piston rod. Push piston rod into piston until ball end of rod contacts seat.

90 89 88 87

C

B

A