31

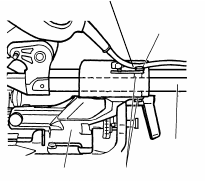

2. Adjusting a loose slide pipe

After extended use of the power tool, the slide pipe

(A) and the bushing can become loose due to

vibration. Never operate the tool if any components

are loose to avoid personal injury.

(1) Loosen the 8mm nut and tighten the two 8mm

hexagon socket set screws until the power tool

operates smoothly without looseness.

(2) Properly tighten the 8mm nut after completing

these adjustment.

Fig. 52

3. Inspecting the carbon brushes

For your continued safety and electrical shock protection, carbon brush inspection and

replacement on this tool should ONLY be performed by a Hitachi Authorized Service

Center.

4. About Handling the Motor (see Fig. 1)

Winding of the motor is said to be the heart of this tool. Exercise utmost caution not to

damage the winding by exposing it to wash oil or water.

NOTE: Accumulation of dust and the like inside the motor can result in a malfunction.

After using the motor for 50 hours or so, carry out no-load running, and blow

in the dry air from a wind hole at the motor's rear. Such action is effective to

discharge dust and the like.

5. Inspecting the screws

Regularly inspect each component of the power tool for looseness.

Re-tighten screws on any loose part.

WARNING: To prevent personal injury, never operate the power tool if any

components are loose.

6. Inspecting the lower guard for proper operation

Before each use of the tool, test the lower guard (see Fig. 7) to assure that it is in good

condition and that it moves smoothly.

Never use the tool unless the lower guard operates properly and it is in good mechanical

condition.

7. Storage

After operation of the tool has been completed, check that the following has been

performed:

(1) Trigger switch is in OFF position,

(2) Power plug has been removed from the receptacle,

Slide

Pipe (A)

Holder (A)

Bushing

8mm Hex. Socket

Set Screw

8mm Nut

01Eng_C10FSH_Eng 3/29/07, 12:30 PM31