• To avoid injury from an accidental start, turn the switch OFF and remove the plug from the power source before making

any adjustments.

• All electrical or mechanical repairs should be done only by qualified service technicians. Contact Hitachi Authorized

Service Center.

GENERAL

English

– 18 –

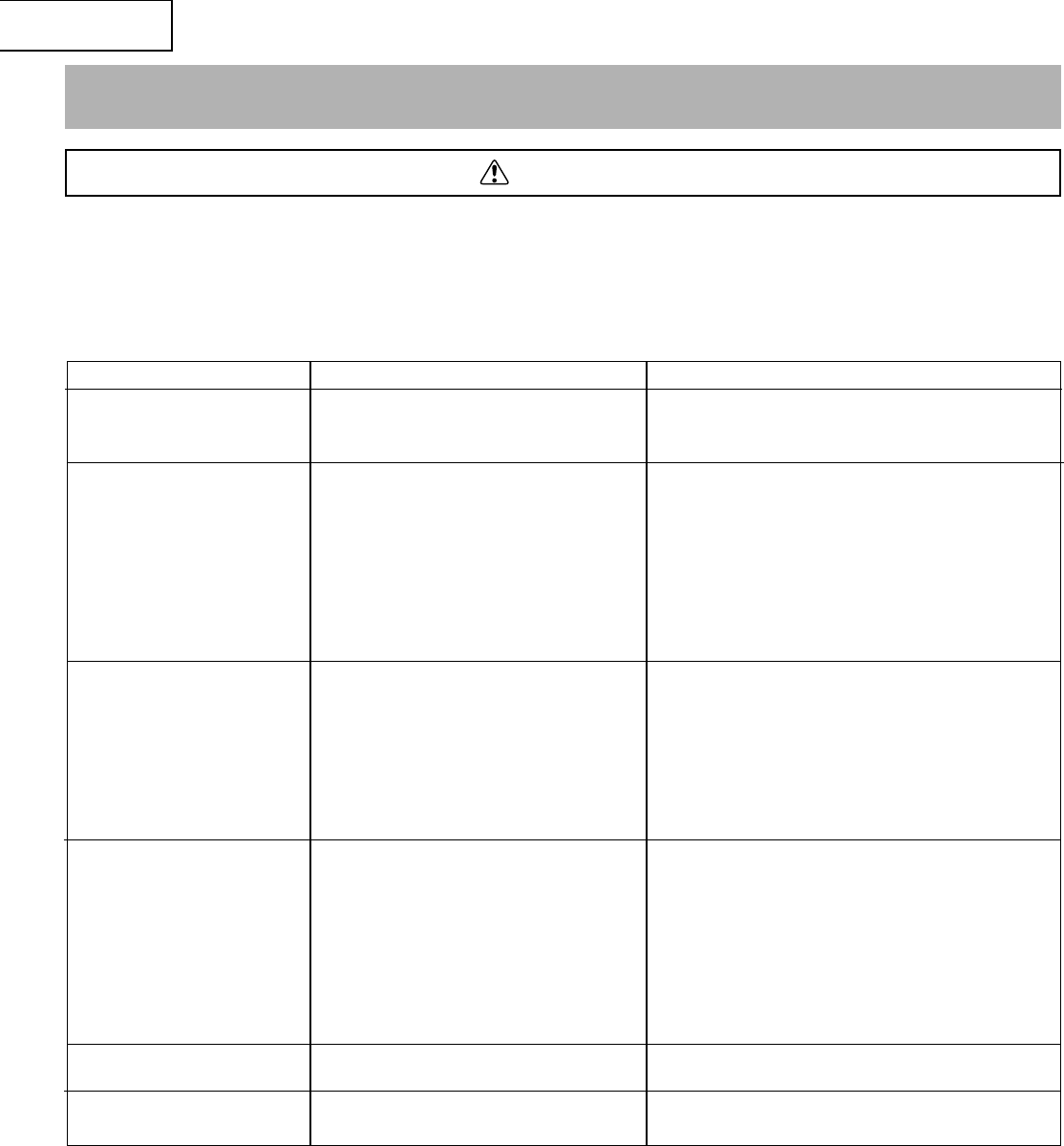

TROUBLESHOOTING GUIDE

PROBABLE CAUSE

1. Not tracking properly.

2. Defective blade.

1. Blade too loose.

2. Cutting too small a radius.

3. Dull blade.

4. Overloading motor.

1. Too much tension on the blade.

2. Kink in the blade caused by cutting too

small a radius or turning the material

too fast when cutting.

3. Cutting incorrect material.

1. Work not square.

2. Rate of feed too great.

3. Blade guides not adjusted properly.

4. Upper blade guide too far from

workpiece.

5. Dull blade.

6. Blade guide assembly loose or

blade thrust bearing loose.

1. Too much feed.

2. Blade too coarse.

1. Dust collection bag full.

2. Impeller loose or broken.

PROBLEM

Blade does not run in the

center of the upper wheel.

Band saw slows down

when cutting.

Blades braking.

Crooked cuts.

Rough cuts.

Dust collection not working.

REMEDY

1. Adjust tracking. See ASSEMBLY AND

ADJUSTMENTS section BLADE TRACKING.

2. Replace blade.

1. Adjust blade tension. See SCHEMATIC A,

page 56. Adjust TENSION ROD, Ref. 0053,

clockwise to increase tension; counterclockwise

to decrease tension.

2. Stop feeding, back up the material slightly,

until the band saw speeds up.

3. Replace blade.

4. Slow down, trying to cut too fast. See MOTOR

TROUBLESHOOTING GUIDE on page 19.

1. Adjust blade tension. See SCHEMATIC A,

page 56. Adjust TENSION ROD, Ref. 0053,

clockwise to increase tension; counterclockwise

to decrease tension.

2. Use correct cutting technique. See OPERATION

section GENERAL CUTTING.

3. See OPERATION section BLADE SELECTION.

1. Use miter gauge; adjust tilt of head at 90°.

2. Reduce rate of feed.

3. Move both guide blocks within .002″ from blade

(use gauge).

4. Adjust upper guide to just clear workpiece by 1/8″.

5. Replace blade.

6. Tighten blade thrust bearing within 1/64″

behind blade back.

1. Reduce feed.

2. Replace with finer blade.

1. Empty dust collection bag.

2. Replace impeller.

WARNING