English

10

ASSEMBLY AND OPERATION

APPLICATIONS

⅜

Removal of casting fin and finishing of various type

of steel, bronze and aluminum materials and

castings.

⅜

Grinding of welded sections or sections cut by

means of an acetylene torch.

⅜

Grinding of synthetic resins, slate, brick, marble.

WARNING:

To avoid the risk of serious injury, NEVER use this

grinder with cup wheels and/or saw blades.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized

conforms to the power source requirements

specified on the product nameplate.

NOTE:

When connected to the power supply, the built-in

electronic control circuit shifts to standby status

and the grinder becomes slightly warm, but this is

not a malfunction.

CAUTION

Do not operate from a direct current power source,

engine generator, booster or any other type of

transformer. Doing so may not only cause damage

to the grinder, but may lead to accidents.

2. Power switch

Ensure that the switch is in the OFF position. If the

plug is connected to a receptacle while the switch

is in the ON position, the power tool will start

operating immediately and can cause serious injury.

When the kickback protection, 0 voltage re-start

protection or overload protection feature has been

activated, return the power switch to the OFF

position and wait for 1 second or more before re-

starting the power tool.

3. Extension cord

When the work area is far away from the power

source, use an extension cord of sufficient

thickness and rated capacity. The extension cord

should be kept as short as practicable.

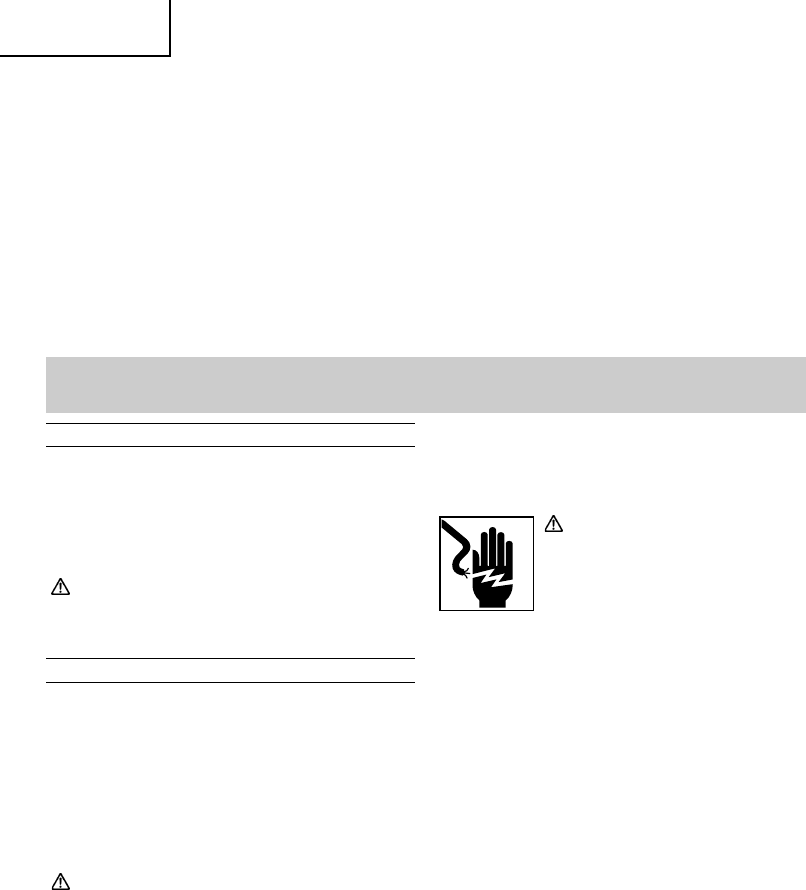

WARNING:

Damaged cord must be replaced or

repaired.

4. Check the receptacle

If the receptacle only loosely accepts the plug, the

receptacle must be repaired. Contact a licensed

electrician to make appropriate repairs.

If such a faulty receptacle is used, it may cause

overheating, resulting in a serious hazard.

5. Check your work environment

Ensure the following before operation;

⅜

No flammable gas, liquid, or object at

worksite.

⅜

When grinding thin steel sheet it may cause

a high booming noise.

To avoid such noise, place a rubber mat under

the workpiece.

⅜

Clear the area of children or unauthorized

personnel.

6. Mounting the wheel guard

Be sure to mount the wheel guard at an angle that

will protect the operator’s body from injury by a

broken wheel piece.

[How to attach and adjust the wheel guard] (Fig. 2)

⅜

Set the wheel ass’y to the packing gland.

⅜

Tighten M5 screw to secure the wheel guard

while the lever is in closed position.

⅜

Perform the adjustment, of the wheel guard

while the lever is released. (Loosen M5 screw

and readjust if the wheel guard does not

rotate smoothly.)

Electronic Control

The grinder has an electronic speed control which

provides:

⅜

full speed at all times in the range up to rated load.

⅜

soft-start.

⅜

variable speed

⅜

Kickback Protection

The kickback protection feature cuts off the power

to the motor and stops the power tool in the event

of a sudden drop in the rotational speed of the

wheel during operation (for example, if the wheel

locks during cutting operation, etc.).

⅜

0 Voltage Re-start Protection

The 0 voltage restart protection feature prevents

the power tool from restarting after the power has

been temporarily cut off during operation.

⅜

Overload Protection

The overload protection feature shuts off the power

to the motor in the event of overloading of the

motor or a conspicuous reduction in rotational

speed during operation.

NOTE:

The grinder is equipped with a rotational speed

control circuit. The rotational speed may fluctuate

slightly due to the conditions of use and working

voltage.

01Eng_G12VA_US 8/3/09, 17:5110