English

12

NOTE:

Use caution not to turn the dial scale to any value

below 1 or above 6.

Fig. 4

CAUTION:

When using the grinder in the immediate vicinity

of welding equipment, the rotational speed may

become unstable. Do not use the grinder near

welding equipment.

4. Use light grinding pressure.

There is no need to press hard when grinding.

Usually the grinder’s own weight is sufficient to

allow the required light contact with the surface to

be ground.

Do not apply the grinding wheel strongly to the

grinding surface. The grinder makes use of

electronic circuit, so during application of load

rotates at high speed, so ample grinding effect can

be obtained by applying light pressure. If a strong

grinding pressure or other abnormal load is

applied, the overload protection circuit will operate

and make the grinder stop rotating, so please stop

applying load immediately. Following this,

switching the power OFF and then ON again, will

cause the rotation to increase to the regular speed.

CAUTION:

When using the tool at any value except the full

speed (Dial scale 6), the motor cannot be

sufficiently cooled due to the decreased number

of revolution. This could result in the risk of

burning and damaging the motor before an

overload protective mechanism starts to function.

Make sure that you use the tool by lightly applying

it to the surface of material when you use it at

any value except the full speed (Dial scale 6).

WARNING:

Do not press the grinder forcibly against the

surface to be ground. Heavy pressure can result

in wheel breakage and serious injury. It can also

damage the surface being ground or damage the

grinder’s motor.

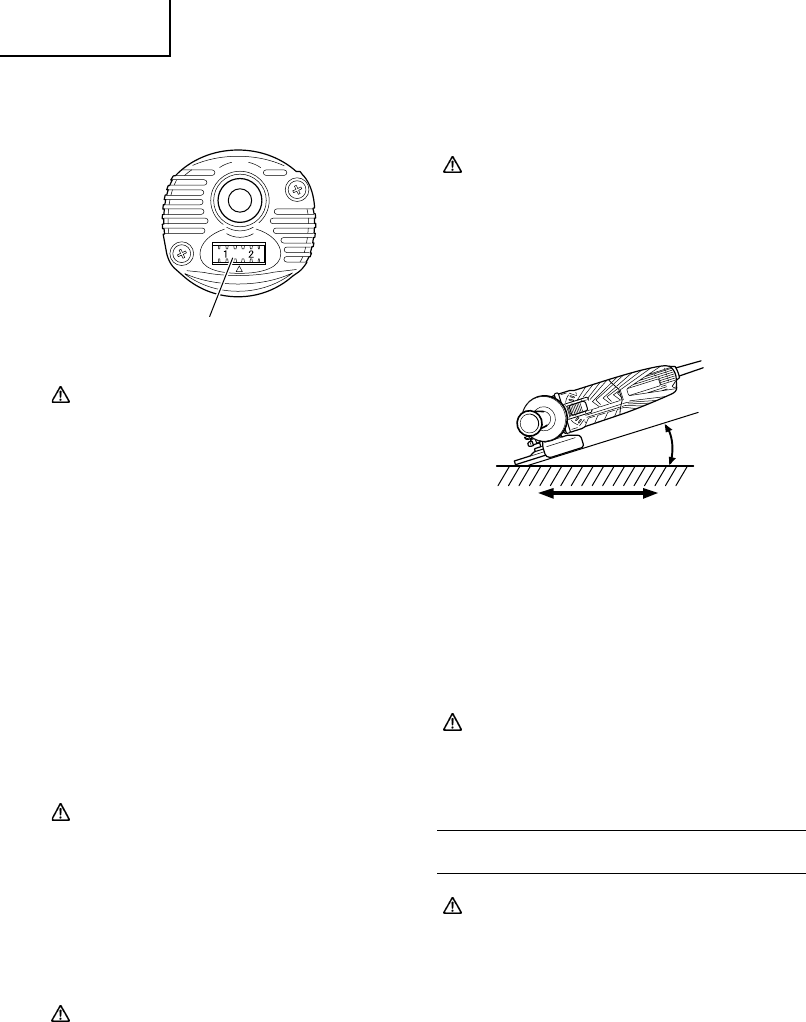

5. Use proper grinding angle.

Grind only with the wheel’s edge by lifting the

grinder 15° to 30°, as shown in Fig. 5.

CAUTION:

Do not use the entire surface of the depressed

center wheel. Use only the edge of the depressed

center wheel.

6. Move the grinder in the proper direction.

When using a new depressed center wheel in

direction A (Fig. 5), the wheel edge may cut into the

workpiece. In this case, grind in direction B (Fig. 5).

Once the wheel edge is worn, the workpiece can be

ground in both directions.

Fig. 5

NOTE:

The wheel provided (resinoid wheel) is rated as

Class A grain and # 36 grain size. It is most suitable

for heavy grinding of steel and other types of

materials.

7. Adjust operation to desired finish.

For a fine finish, decrease pressure by lifting

slightly. Grind slowly and at the appropriate speed.

CAUTION:

The revolving depressed center wheel will create

air turbulence.

Do not lay the grinder down in areas of dust or

dirt until it has come to a complete stop.

DEPRESSED CENTER WHEEL ASSEMBLY

AND DISASSEMBLY

WARNING:

Never attempt to assemble or disassemble the

depressed center wheel, unless the power switch

is in the “OFF” position and the electrical cord has

been disconnected from the receptacle.

1. Assembly

(1) Turn the disc grinder upsidedown so that the

spindle is facing upward.

(2) Align the oval-shaped indentation of the wheel

washer with the notched part of the spindle, then

attach them.

(3) Fit the protuberance of the depressed center wheel

onto the wheel washer.

15° – 30°

AB

Dial

01Eng_G12VA_US 8/3/09, 17:5112