English

13

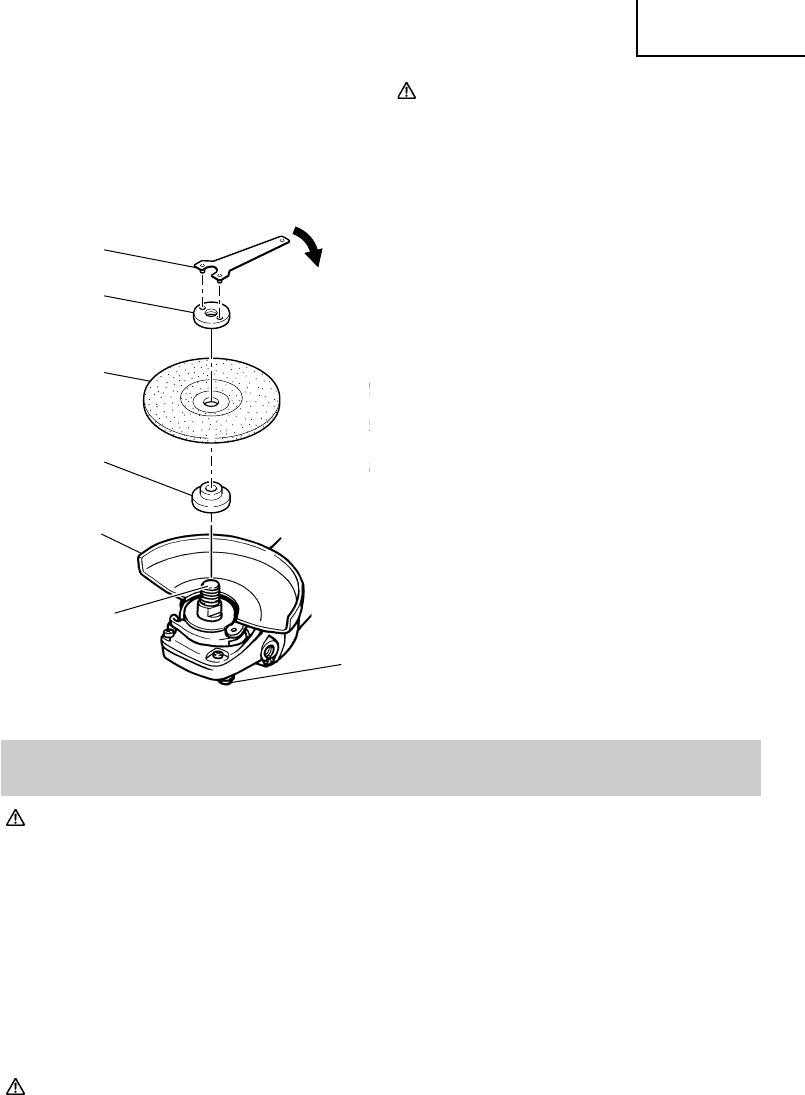

(4) Screw the wheel nut onto the spindle.

(5) While pushing the push button with one hand, lock

the spindle by turning the depressed center wheel

slowly with the other hand.

Tighten the wheel nut by using the supplied

wrench as shown in Fig. 6.

Fig. 6

MAINTENANCE AND INSPECTION

Wheel

nut

Wheel

guard

Push button

Wrench

Wheel

washer

Spindle

Depressed

center

wheel

1. Replacing the depressed center wheel

Replace the depressed center wheel when it has been

worn out to about 2-3/8" (60mm) in external diameter.

Confirm that there is no crack or any damage to the

depressed center wheel. If there is a crack or a

transformation in the wheel, replace it immediately.

2. Inspecting the screws

Regularly inspect all screws and ensure that they

are fully tightened. Should any of the screws be

loosened, retighten them immediately.

WARNING:

Using this grinder with loosened screws is

extremely dangerous.

CAUTION:

Tighten the wheel nut securely and confirm that

the depressed center wheel does not wobble.

2. Disassembly

To remove the depressed center wheel, simply

reverse the above-mentioned procedure.

WARNING:

ⅷ

Be sure to switch power OFF and disconnect the plug from the receptacle during maintenance and inspection.

ⅷ

Using cracked, deformed or damaged wheels can lead to wheel breakage and resulting serious injury.

3. Confirm that there is no damage in the wheel

guard, the electrical cord and the housing, etc.

Check that the on/off switch operates normally.

4. Inspecting the carbon brushes

For your continued safety and electrical shock

protection, carbon brush inspection and

replacement on this tool should ONLY be performed

by a HITACHI AUTHORIZED SERVICE CENTER.

5. Replacing supply cord

If the supply cord of Tool is damaged, the Tool

must be returned to Hitachi Authorized Service

Center for the cord to be replaced.

Tighten

01Eng_G12VA_US 8/3/09, 17:5113