20

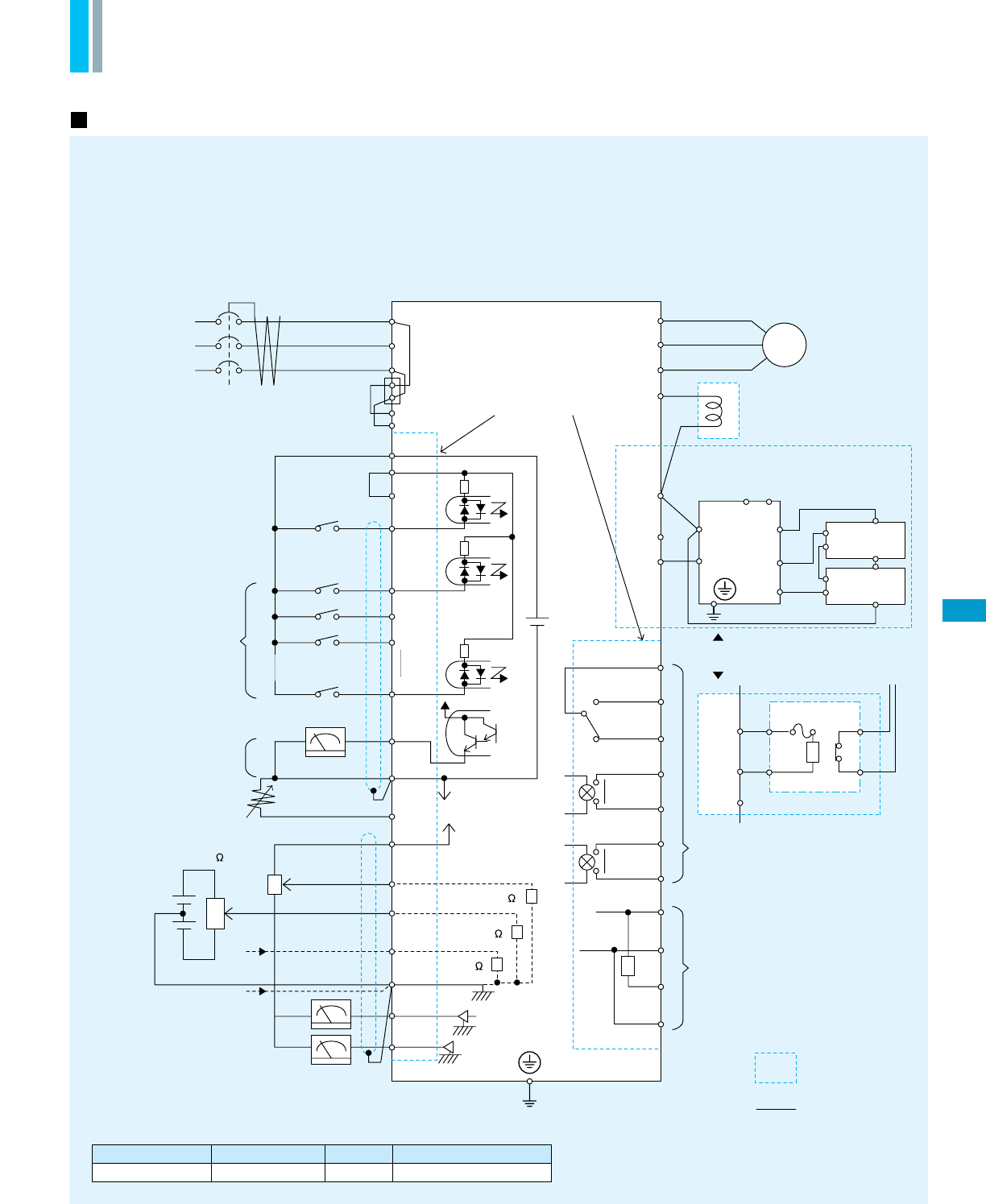

CONNECTING DIAGRAM

200V

-

240V 10%

50/60Hz 5%

Short-circuit bar

Forward command

Intelligent

input terminals

(5 terminals)

Thermistor

DC0

-

10V(12-bit)

DC0

-

10V

(8-bit)

DC4

-

20mA

(8-bit)

(G)

DC

–

10

–+

10V

(12-bit)

Current input

4

-

20mA

(12-bit)

Analog input

Analog output

FM Monitor output

(PWM)

RS485

Serial communication port

Intelligent output terminals

DC link choke

IM

Removable terminals

L300P

R

(

L1

)

S

(

L2

)

T

(

L3

)

R0

P24

PLC

CM1

FW

5

4

3

1

FM

CM1

O2

OI

L

AM

AMI

10k

10k

100

TH

H

O

T0

SN

RP

SN

SP

12C

12A

11C

P

RB

P

RB

N

Braking resistor (RB)

11A

AL2

AL1

AL0

NN

P

AL1

Dynamic braking unit (BRD)

AL2

RB

R1

R2

RB

P

(

+1

)

PD

(

T3

)

W

(

T2

)

V

(

T1

)

U

DC24V

DC10V

-

+

Terminal Name

Common

FW, 1, 2, 3, 4, 5

P24

FM, TH

CM1

H, O, O2, OI, AM, AMI

L

AL1

AL2

AL1

AL2

RB

P

RB

P

(+)

(

-

)

(Inverter)

(To operating circuit)

For 18.5kW(25HP) and over

For up to 15kW(20HP)

In case of 400V class,

place a transformer for operating circuit

to receive 200V.

Option

Customer wiring

(Outside the inverter)

SOURCE TYPE LOGIC

Frequency

setting device

500

-

2k

R

T

(

J51

)

(*

2

)

(*2)Remove connection with J51

when RoTo power is supplied

externally

Control power source