English

10

Air consumption table

Air compressor size formula

Amount of air required

=number of Staplers

average staples driven each minute per

Stapler

air consumption at given air pressure

safety factor (always 1.2)

Example: 3 Staplers (N3804AB3

(S)) operating at

100 psi driving 30 staples per minute

Amount of air required

=3 30 .025 (.73) 1.2

=2.7 CFM (ft

3

/min) (78.8 ltr/min)

After making the calculations as shown above, you

should find a compressor providing 2.7 CFM of air

that is required.

LUBRICATION

It is important that the Stapler be properly lubricated.

Without proper lubrication, the Stapler will not work

properly and parts will wear prematurely.

⅜

Use Hitachi pneumatic tool lubricant.

Do not use detergent oil or additives. These

lubricants will harm the O-rings and other rubber

parts. This will cause the Stapler to malfunction.

⅜

Filter-regulator-lubricator units should always be

used.

Keep the lubricator filled with Hitachi pneumatic

tool lubricant.

⅜

If a lubricator is not available, supply 5 – 10 drops

of Hitachi pneumatic tool lubricant into the air plug

on the Stapler twice a day.

COLD WEATHER CARE

⅜

Do not store the Stapler in a cold weather

environment.

Keep the Stapler in a warm area until beginning

the work.

⅜

If the Stapler is already cold, bring it in a warm

area and allow the Stapler to warm up before use.

1

Reduce the air pressure to 40 psi (2.8 bar 2.8

kgf/cm

2

).

2

Remove all staples from the Stapler.

3

Connect the air hose and free-fire (blank-fire)

the Stapler.

The lowered air pressure will be enough to

free-fire the Stapler.

Slow speed operation tends to warm up the

moving part.

CAUTION:

Do not free-fire the Stapler at high pressure.

TESTING THE STAPLER

DANGER

Operators and others in

work area MUST wear

safety glasses with side

shields which conforms

to ANSI Z87.1

specifications.

WARNING

Never use Stapler unless push lever is

operating properly.

Before actually beginning the stapling work, test the

Stapler by using the checklist below. Conduct the tests

in the following order.

If abnormal operation occurs, stop using the Stapler and

contact a Hitachi authorized service center immediately.

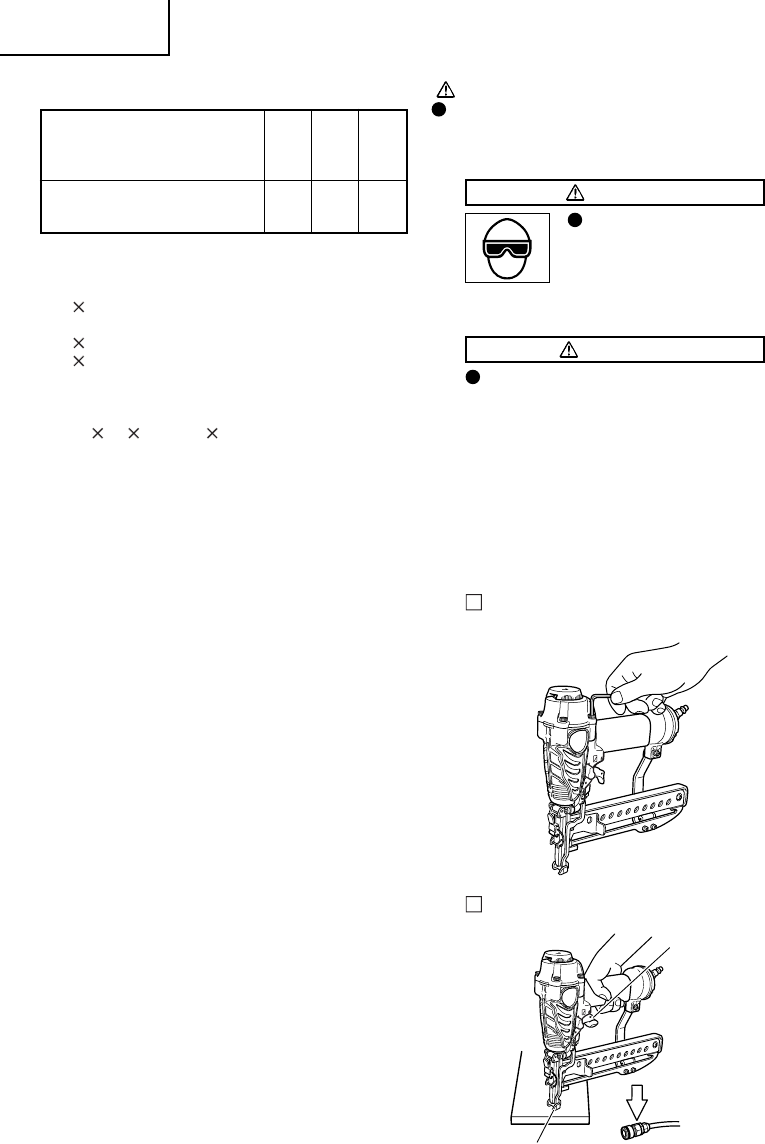

(1) DISCONNECT AIR HOSE FROM STAPLER.

REMOVE ALL STAPLES FROM STAPLER.

ALL SCREWS MUST BE TIGHTENED.

If any screws are loose, tighten them.

THE PUSH LEVER AND TRIGGER MUST

MOVE SMOOTHLY.

psi 80 90 100

Operating pressure (bar) (5.5) (6.2) (6.9)

(kgf/cm

2

) (5.6) (6.3) (7)

Air consumption

ft

3

/cycle .019 .023 .025

(ltr/cycle) (.55) (.64) (.73)

Push lever

Do not connect

air hose

Trigger