English

15

2

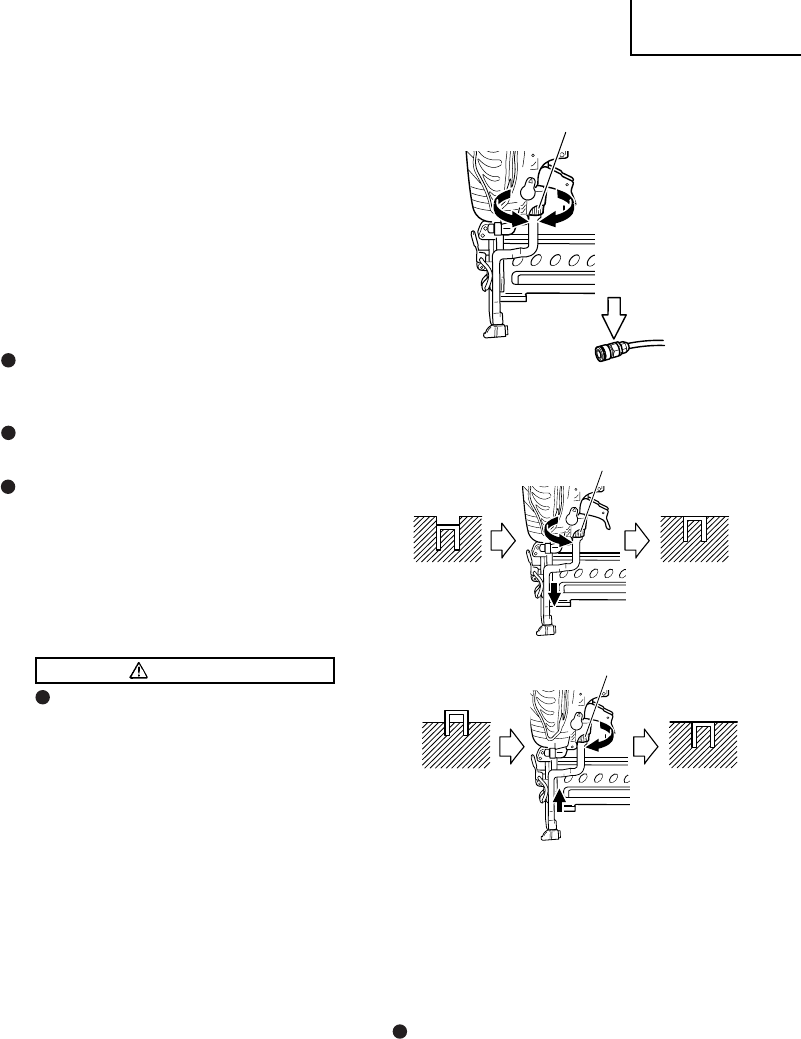

If staples are driven too deep, turn the adjuster to

the shallow side.

If staples are driven too shallow, turn the adjuster

to the deep side.

1

DISCONNECT AIR HOSE FROM STAPLER.

Disconnect

air hose

15

Adjuster

Too Deep

Turn Adjuster

Flush

3

Stop turning the adjuster when a suitable position

is reached for a stapling test.

4

Connect the air hose.

ALWAYS WEAR SAFETY GLASSES.

Perform a stapling test.

5

DISCONNECT AIR HOSE FROM STAPLER.

6

Choose a suitable position for the adjuster.

NOTE:

The staple might not drive deep enough if using

high pressure with the adjuster set upwards

(shallow side) due to factors such as the material

hardness or staple type.

If that happens, reduce pressure and set the

adjuster to lowest position so the staple drives in

at a good position.

Too Shallow

Turn Adjuster

Flush

After stapling:

1) disconnect air hose from the Stapler;

2) remove all staples from the Stapler;

3) supply 5 – 10 drops of Hitachi pneumatic tool

lubricant into the air plug on the Stapler; and

4) open the petcock on the air compressor tank

to drain any moisture.

ADJUSTING THE STAPLING DEPTH

WARNING

When adjusting the Adjuster, be sure to

remove your finger from the trigger and

disconnect the air hose from the stapler.

To assure that each staple penetrates to the same depth,

be sure that:

1) the air pressure to the Stapler remains constant

(regulator is installed and working properly), and

2) the Stapler is always held firmly against the

workpiece.

If staples are driven too deep or shallow into the

workpiece, adjust the stapling in the following order.

NOTE:

If all warnings and instructions are followed, safe

operation is possible with two systems:

SINGLE SEQUENTIAL ACTUATION MECHANISM,

CONTACT

ACTUATION MECHANISM.

Always handle staples and package carefully. If

staples are dropped, collating bond may be broken,

which will cause mis-feeding and jamming.

The SINGLE SEQUENTIAL ACTUATION MECHANISM

may reduce the possibility of bodily injury to you or

others in the work area compared to the CONTACT

ACTUATION MECHANISM. This is because it is less

likely to drive an unwanted nail if you keep the trigger

pulled and accidentally bump the push lever against

yourself or others.

The SINGLE SEQUENTIAL ACTUATION MECHANISM

may also reduce the speed of operation compared to

the CONTACT ACTUATION MECHANISM. The SINGLE

SEQUENTIAL ACTUATION MECHANISM is

recommended to inexperienced users.