English

19

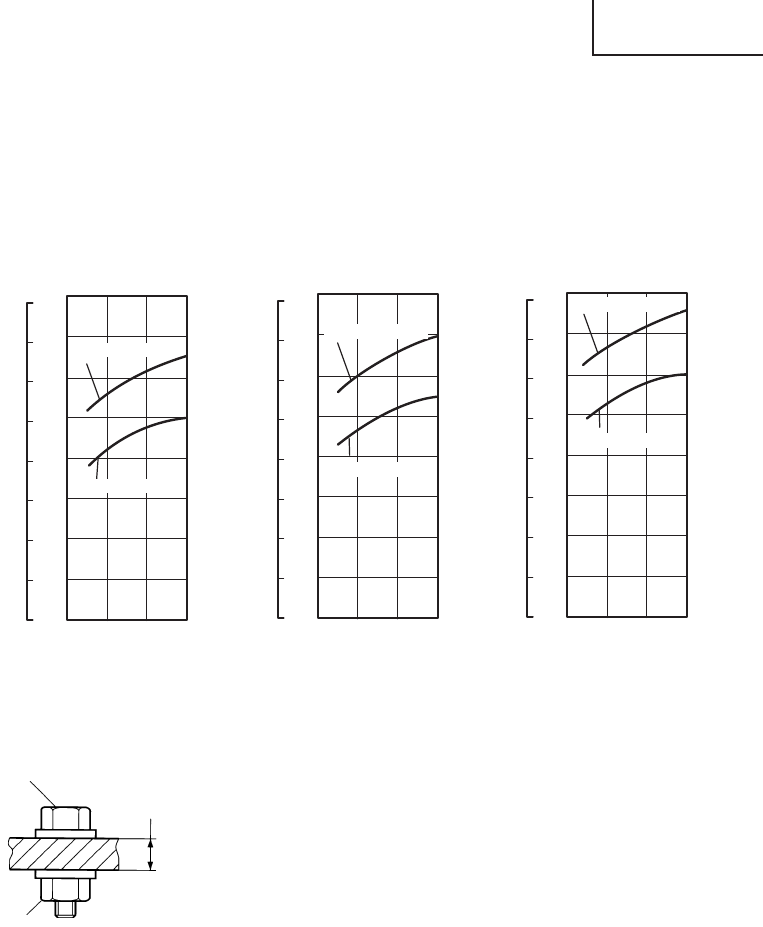

0 123

0

kgf•cm

(in-lbs)

1600

1400

1200

1000

800

600

400

200

N•m

160

140

120

100

80

60

40

20

0

(1390)

(1218)

(1042)

(868)

(695)

(521)

(347)

(174)

0 123

0

kgf•cm

(in-lbs)

1600

1400

1200

1000

800

600

400

200

N•m

160

140

120

100

80

60

40

20

0

(1390)

(1218)

(1042)

(868)

(695)

(521)

(347)

(174)

Tightening time: sec

(Steel plate thickness

t = 3/8" (10 mm))

Tightening time: sec

(Steel plate thickness

t = 1" (25 mm))

Tightening torque

Tightening torque

High strenge bolt

High strenge bolt

Ordinary bolt

Ordinary bolt

3/8"×1-3/6"

(M10×30)

Fig. 15

4. Use a tightening time suitable for the screw

The appropriate torque for a screw differs according to the material and size of the

screw, and the material being screwed etc., so please use a tightening time suitable for

the screw. In particular, if a long tightening time is used in the case of screws smaller

than 5/16” (8 mm), there is a danger of the screw breaking, so please confirm the

tightening time and the tightening torque beforehand.

15/32"×1-3/4"

(M12×45)

Bolt

Steel plate

thickness t

Explanation of strength grade:

4 — Yield point of bolt: 45,500 psi (32 kgf/mm

2

)

8 — Pulling strength of bolt: 56,900 psi (40 kgf/mm

2

)

*The following bolt is used.

Ordinary bolt: Strength grade 4.8

High tensile bolt: Hardness division 12.9

(

)

Fig. 16

Nut

kgf•cm

(in-lbs)

1600

1400

1200

1000

800

600

400

200

N•m

160

140

120

100

80

60

40

20

0

(1390)

(1218)

(1042)

(868)

(695)

(521)

(347)

(174)

0 123

0

Ordinary bolt

Tightening time: sec

(Steel plate thickness

t = 1" (25 mm))

High strenge bolt

Tightening torque

9/16"×1-31/32"

(M14×50)