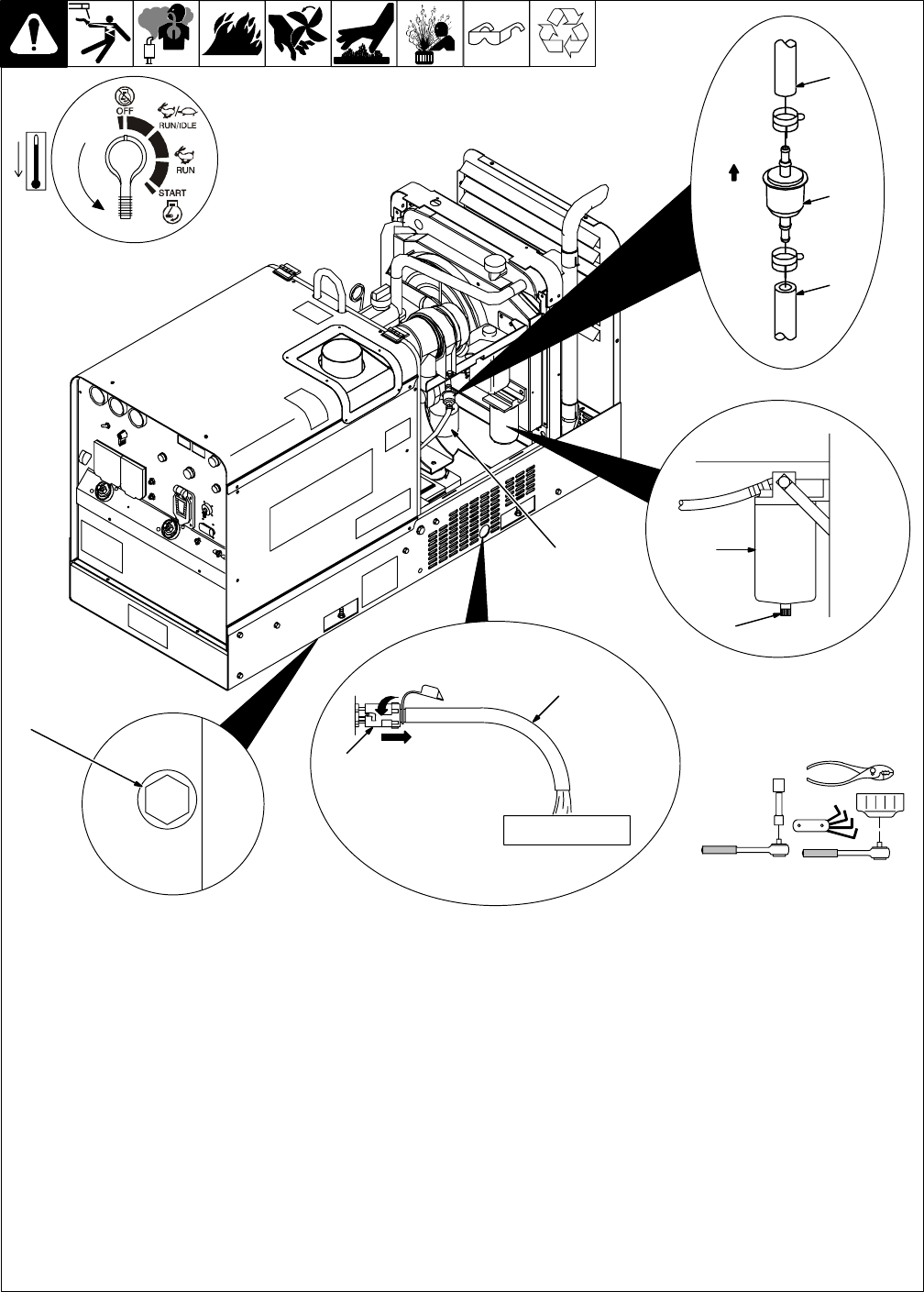

OM-492 Page 28

7-5. Servicing Engine Lubrication And Fuel Systems

Ref. 189 438-A / 802 330-B / S-0842

Tools Needed:

5

4

4

2

3

Y Stop engine and let cool.

1 Oil Filter

2 Oil Drain Valve

3 1/2 ID x 12 in Hose

4 Fuel Line

5 Primary Fuel Filter

6 Secondary Fuel Filter

7 Petcock

8 Fuel Tank Sludge Drain

To change oil and filter:

Pull oil drain hose through access hole in

base. Change engine oil and filter according

to instructions in engine manual.

Y Close valve and valve cap before ad-

ding oil and running engine.

Fill crankcase with new oil to full mark on

dipstick (see Section 4-2).

To drain water from fuel system:

Open secondary fuel filter petcock and

drain water into metal container. Close pet-

cock when water-free fuel flows.

To change fuel filters:

Install new primary fuel filter as shown.

Replace secondary fuel filter according to

engine manual.

Replace fuel lines if cracked or worn.

Wipe up any spilled fuel.

Y After servicing, start engine and

check for fuel leaks.

Stop engine, tighten connections as

necessary, and wipe up fuel.

To change coolant:

Change coolant according to engine manu-

al.

Run engine until engine reaches normal op-

erating temperature. Loosen air bleed

screw to remove air from cooling system.

Tighten screw.

Check coolant level in recovery tank. Add

coolant if necessary.

To drain sludge from fuel tank:

Put metal container under drain, and re-

move sludge drain plug. Reinstall plug

when done.

1

8

9/16 in

FLOW

6

7