OM-499 Page 18

SECTION 5 – OPERATING THE WELDING GENERATOR

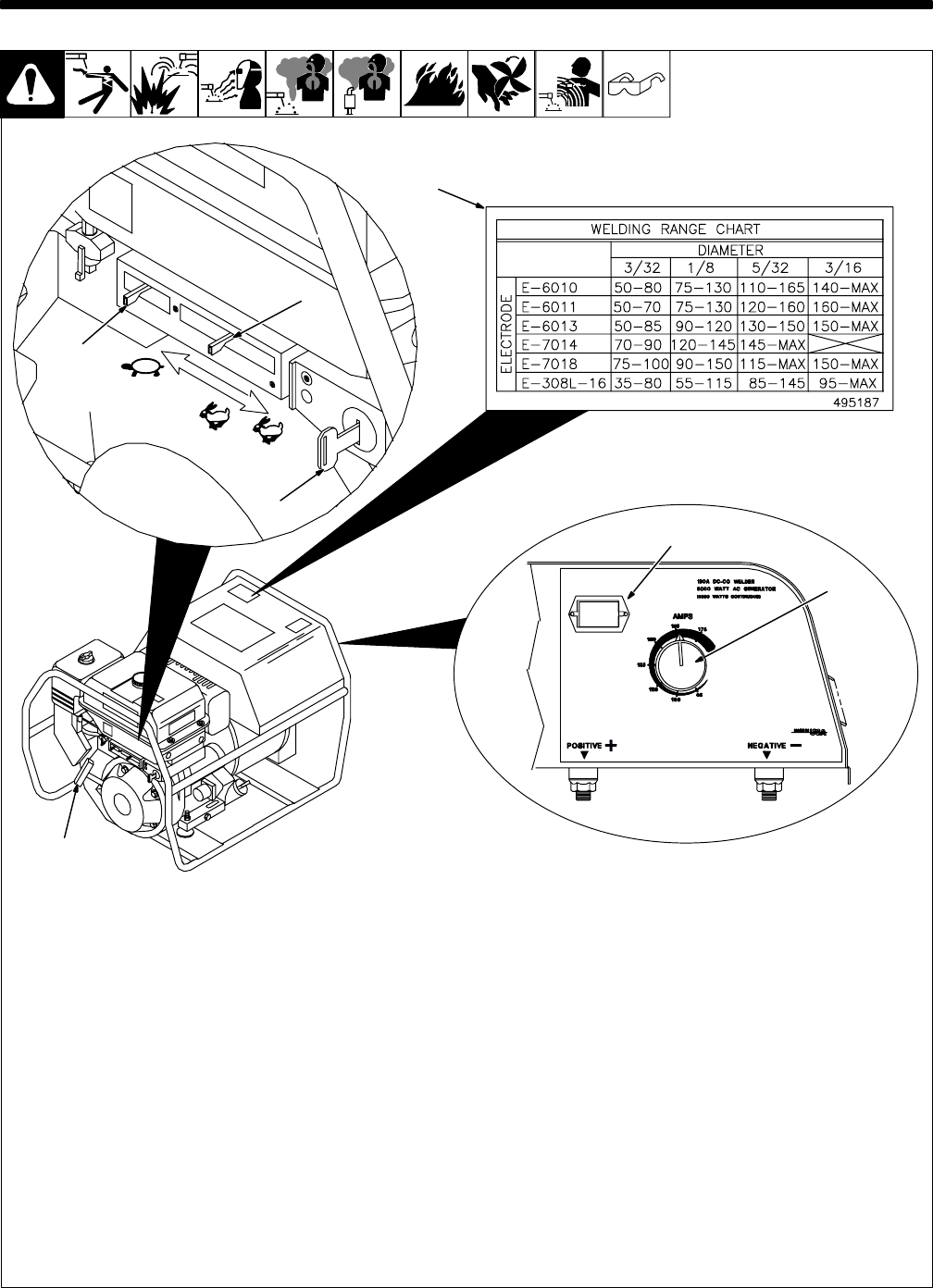

5-1. Controls (Kohler-Powered Units)

802 511-A / 802 0511 / 495 178

6

7

60 Hz

. Weld and generator power output stops if

generator overheats or engine speed is

too low.

1 Engine Switch

Use switch to open ignition circuit, and to stop

engine.

2 Throttle Control Lever

Use lever to select engine speed. Use 50 Hz

or 60 Hz position for 50 or 60 Hz generator

power. Use 60 Hz position for maximum weld

output.

3 Choke Control Lever

Use lever to change engine air/fuel mix. Move

lever to right if starting a cold engine. Move le-

ver to left if starting a warm engine.

To Start (Electric): open fuel valve (see Sec-

tion 4-4), move throttle lever to Idle, set choke,

and turn engine switch to Start position. Open

choke as engine warms. If engine does not

crank, use recoil starting procedure following

to start engine.

Y If engine does not start, let engine

come to a complete stop before at-

tempting restart.

4 Starter Handle

To Start (Recoil): open fuel valve (see Sec-

tion 4-4), move throttle lever to Idle, set choke,

and pull starter handle. Open choke as engine

warms.

To Stop: turn engine switch to Off.

. Always close fuel valve after stopping

unit. Moving unit with fuel valve open may

cause carburetor flooding and make

starting difficult.

5 Engine Hour Meter

6 Welding Range Label

Use label to determine correct weld amper-

age based on electrode size, type, and mate-

rial thickness.

7 Current Control

Use control to select weld amperage. Control

may be adjusted while welding.

To Set Current Control: Use label to deter-

mine correct size electrode for material thick-

ness. Select electrode type and set current

control to corresponding amperage range.

Adjust control to obtain desired weld

performance.

EXAMPLE:

Material Thickness: 1/8 to 1/4 in

Electrode Diameter: 1/8

Electrode Type: E-6013

Current Control Setting: 90 – 120 A

1

3

5

2

4

50 Hz