. A complete Parts List is available at www.HobartWelders.com

OM-230 455 Page 12

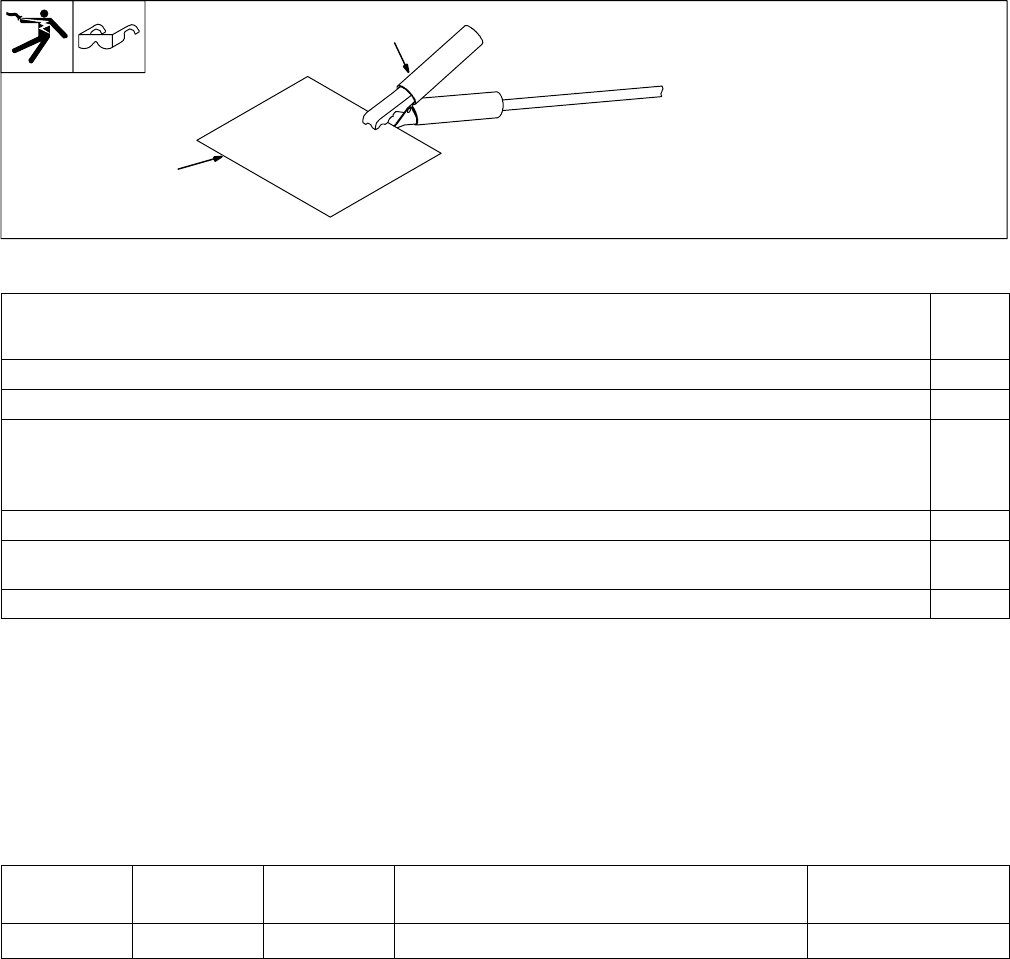

4-6. Connecting Work Clamp

. Do not connect work clamp to

the portion of the workpiece

that will fall when cut.

1 Work Clamp

2 Workpiece

Connect work clamp to a clean,

paint-free location on workpiece, as

close to cutting area as possible.

1

2

Ref 803 915-A

4-7. Electrical Service Guide For 120 VAC

50/60 Hz

Single

Phase

Input Voltage 120

Input Amperes At Rated Output 19

Max Recommended Standard Fuse Rating In Amperes

Circuit Breaker

1

, Time-Delay

2

20

Normal Operating

3

30

Min Input Conductor Size In AWG

4

12

Max Recommended Input Conductor Length In Feet (Meters)

34

(10)

Min Grounding Conductor Size In AWG

4

12

Reference: 2005 National Electrical Code (NEC) (including article 630)

1 Choose a circuit breaker with time-current curves comparable to a Time Delay Fuse.

2 “Time-Delay” fuses are UL class “RK5” .

3 “Normal Operating” (general purpose - no intentional delay) fuses are UL class “K5” (up to and including 60 amp), and UL class “H” ( 65 amp and

above).

4 Conductor data in this section specifies conductor size (excluding flexible cord or cable) between the panelboard and the equipment per NEC Table

310.16. If a flexible cord or cable is used, minimum conductor size may increase. See NEC Table 400.5(A) for flexible cord and cable requirements.

Y Caution: Failure to follow these fuse and circuit breaker recommendations could create an electric shock or fire hazard. These

recommendations are for a dedicated branch circuit that applies to the rated output and duty cycle of the power source.

4-8. Extension Cord Data

Input Voltage

Input Power

Phase

Hertz Conductor Size Max. Cord Length

120 V 1 50/60 12 AWG 50 ft (15 m)