OM-4418 Page 22

6-2. Description Of Controls (See Section 6-1)

1 Engine Switch

Use switch to control ignition circuit, and to

stop engine.

2 Choke Control

Use control to change engine air/fuel mix.

Move control to right (Choke) if starting a cold

engine. Move control to left (Run) if starting a

warm engine.

3 Starter Handle

To Start:

D Open fuel valve (see Section 5-3).

D Turn Engine switch to On.

D Set Choke control.

D Pull starter handle until engine starts.

D Move Choke control to the left (Run) as

the engine warms.

. This unit has a low oil level shutdown to

prevent starting an engine that is too low

on oil. The low oil level shutdown may not

stop a running engine. Check oil level if

the engine does not start, or has stopped

and cannot be restarted.

To Stop: turn engine switch to Off.

. Always close fuel valve after stopping

unit. Moving unit with fuel valve open may

cause carburetor flooding and make

starting difficult.

4 Amperage Control

Use control to select weld amperage. Control

may be adjusted while welding. Set Amper-

age control at max. for full generator power

output at ac receptacles.

To Set Amperage control: Use electrode

chart (see Section 6-3) to determine correct

size electrode. Select electrode type and set

Amperage control to corresponding amper-

age range on nameplate. Adjust control within

selected range to obtain desired weld

performance.

EXAMPLE:

Electrode Type: 6013

Electrode Diameter: 1/8

Amperage control Setting: 80 − 125 A

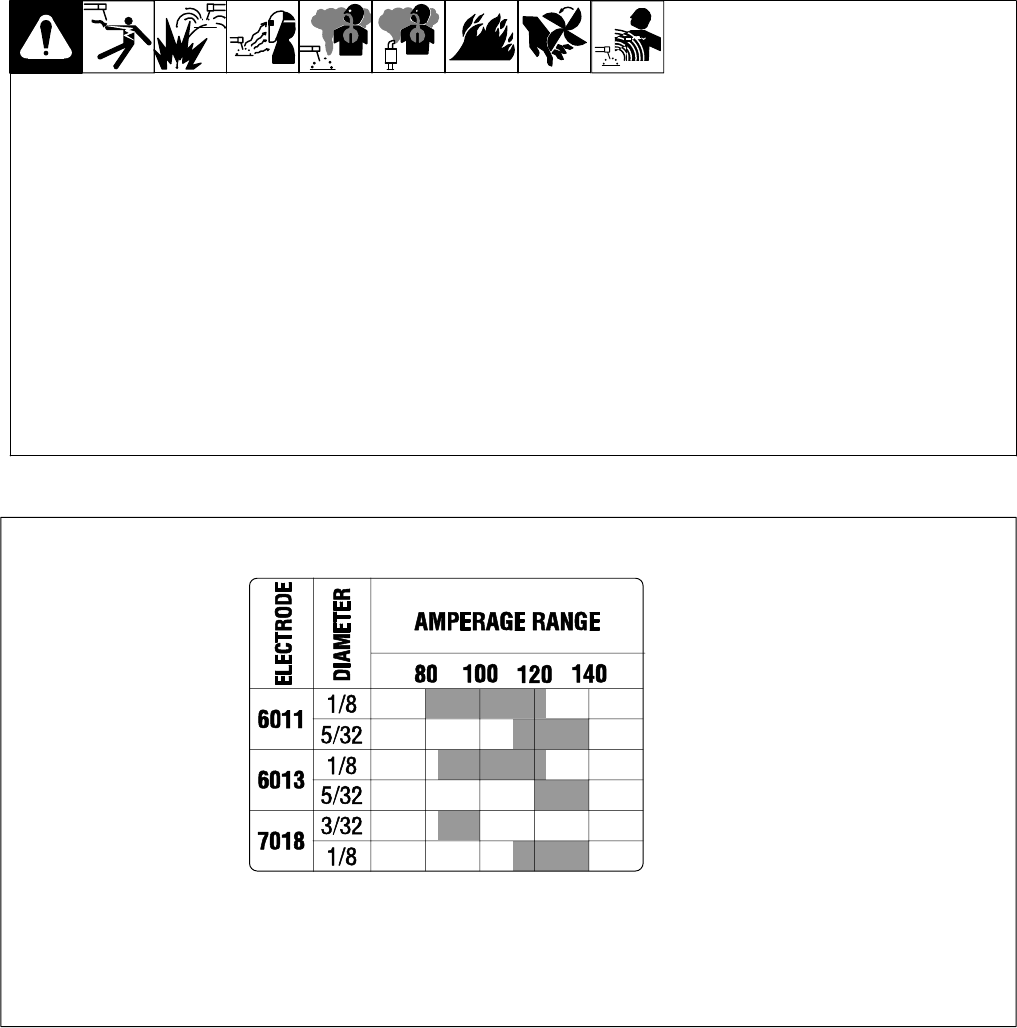

6-3. Amperage Selection Table For Stick (SMAW) Electrodes

226 005-A

Use table to select correct amper-

age for the electrode being used.

. For best results, use Stick

electrodes designated for AC

welding.

Values listed are suggested settings. Actual settings may vary depending on personal preference and/or specific application.

Suggested electrode for beginners is E7018 AC.