English – 17

MAINTENANCE

Carburetor

Your Partner product has been designed and manufactured to

specifications that reduce harmful emissions.

After your unit has been run 8-10 tanks of fuel the engine has

broken in. To ensure that your unit is at peak performance and

producing the least amount of harmful emissions after break in,

have your authorized servicing dealer, who has a revolution

counter at his disposal, to check your carburetor for optimum

operating conditions.

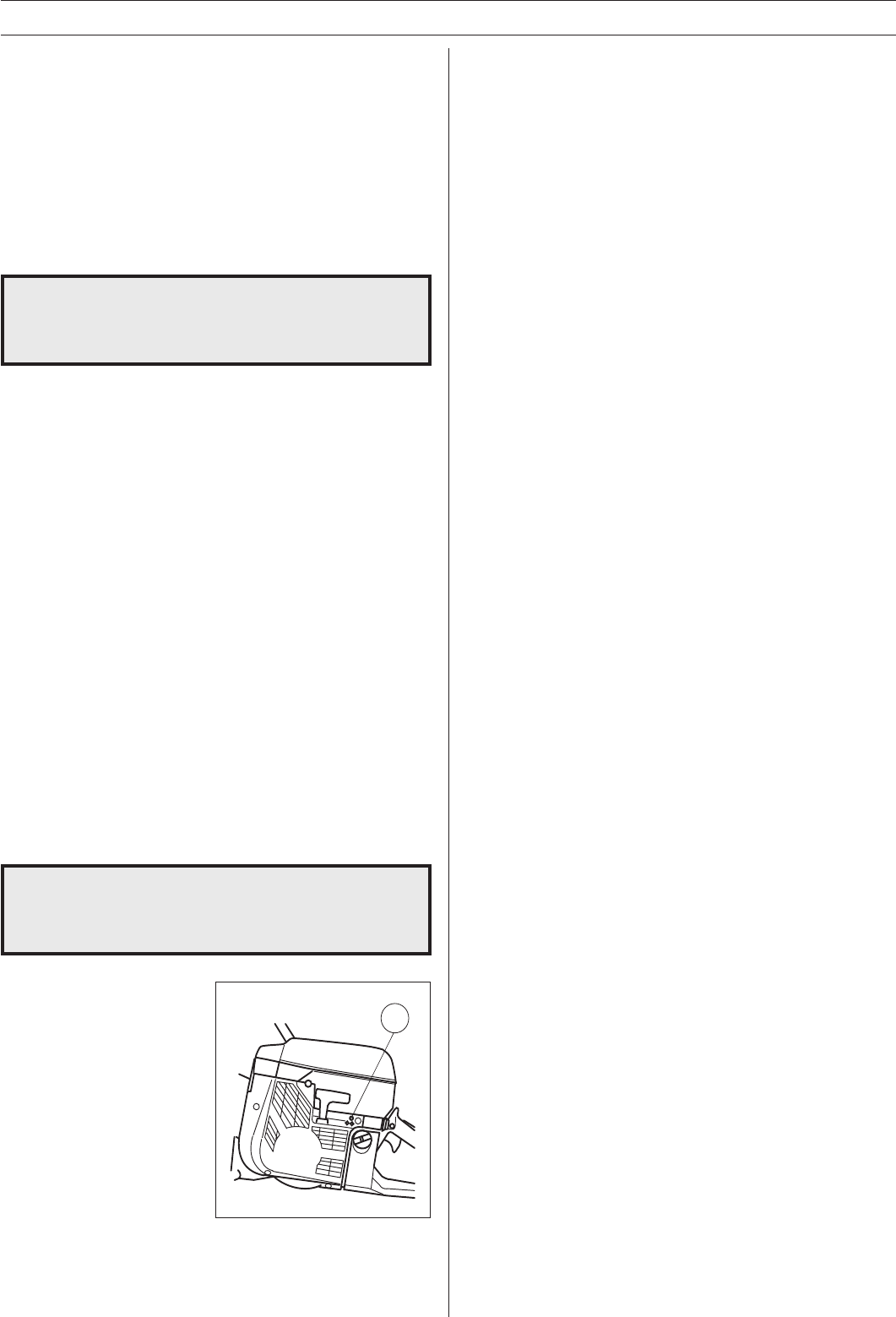

Carburetor

T

Contact your servicing dealer, if the idle speed

setting cannot be adjusted so that the chain

stops. Do not use the cut-off saw until it has

been properly adjusted or repaired.

!

Final setting of the idling speed T

Adjust the idling speed with the screw T. If it is necessary to re-

adjust, first turn the idle speed adjusting screw T clockwise, until

the chain starts to rotate. Then turn, counter-clockwise until the

chain stops. A correctly adjusted idle speed setting occurs when

the engine runs smoothly in every position. It should also be

good margin to the rpm when the chain starts to rotate.

Recommended idling speed: 2 500 rpm.

WARNING! Do not start the cut-off saw

without the bar, chain and cover fitted.

Otherwise the clutch can come loose and

cause personal injury.

Functioning, Final setting

!

Operation

• The carburetor governs the engine speed via the throttle.

Air/fuel are mixed in the carburetor

Jets

The carburetor is equipped with fixed jets to ensure the engine

always receives the correct fuel air mixture.

If the engine lacks power or accelerates poorly do the following:

• Inspect or, if necessary, replace the air filter.

• If this does not help, contact an authorised service workshop.