3

PLACING TOOL IN SERVICE

LUBRICATION

Ingersoll--Rand No. 10

Always use an air line lubricat or with these tools.

We recommend the following Filter--Lubricator-- Regulator

Unit:

F o r U S A -- N o . C 0 8 -- 0 2 -- F K G 0 -- 2 8

Before operating the tool and after each two to three

hours of operation, unless an air line lubricator is used,

detach the air hose and inject severa l drops of

Ingersoll--Rand No. 10 Oil into the air inlet.

When the tool is to be idle for a period exceeding 24

hours, lubricate it in the regular manner and operate it for

5 seconds. This will coat the internal parts with oil and

prevent rusting while the tool is idle.

Never use a heavy oil or oil that forms a gum.

If the action of the tool becomes sluggish, in a well

ventilated area, remove the a ir hose, pour about one

tea spoonful of a clean, suitable cleaning solution into the

air inlet and operate the tool for not more than thirty

seconds. Immediately, foll ow this treatment with an

injection of Ingersoll--Rand No. 10 Oil.

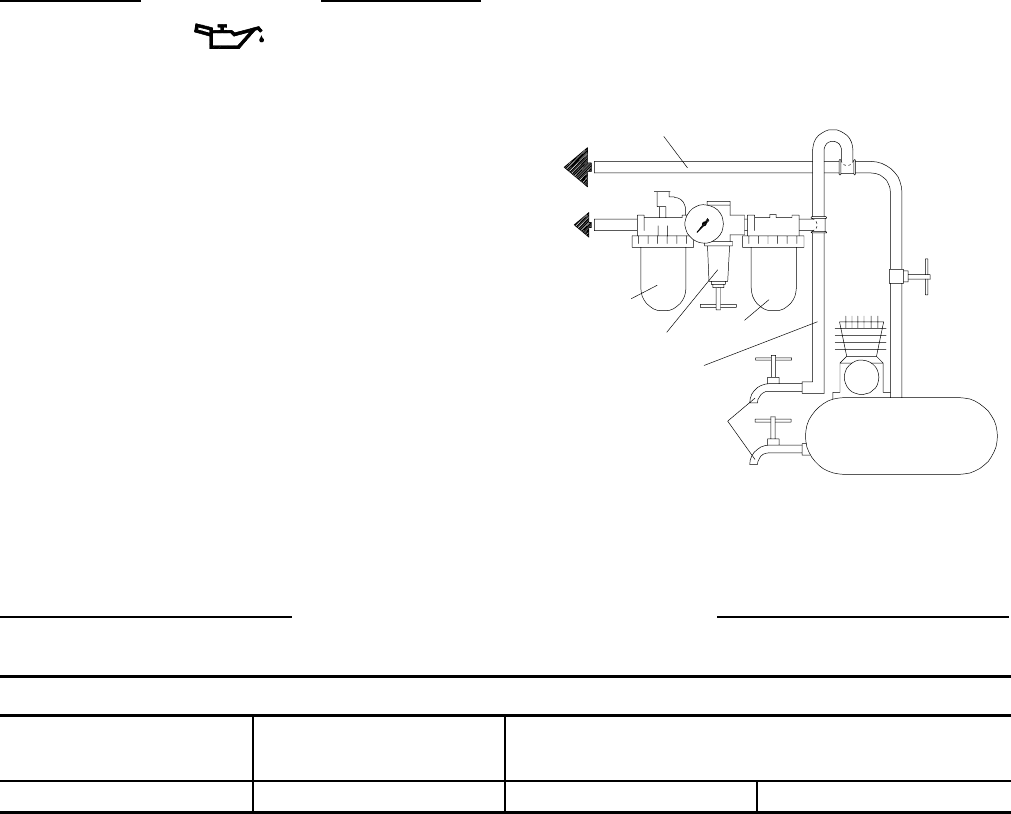

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

FILTER

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

COMPRESSOR

(Dwg. TPD905--1)

HOW TO ORDER AN AIR HAMMER

PISTOL GRIP WITH TRIGGER THROTTLE

Piston Stroke

Model Impacts/min. in mm

132 1 725 4 101