3

SAW SPECIFIC WARNINGS (Continued)

• Keep hands and clothing away from the blade.

The blade of a Circular Saw will coast before stopping

after the throttle is released.

• Do not stop rotation of blade by putting lateral

pressure on it.

• Operate the Saw only when standing on a stable

platform and holding the Saw with two hands.

Do not operate the Saw while standing on a ladder.

• Rest the guide plate fully on the workpiece when

operating.

• Do not force the Saw into the workpiece. The Saw may

kick back if the blade is forced or pinched while

making a cut.

• Always use genuine Ingersoll–Rand Flanges provided

with the Saw. Never use a substitute.

• Mount the blade and flanges as instructed in this

manual. Always mount the blade so that the arrow on

the blade and the arrow on the Swing Guard point in

the same direction.

• Never operate the Saw without the Flange Retaining

Screw installed in its proper place in the end of the

Arbor. Always securely tighten the Flange Retaining

Screw as instructed in this manual before operating

the Saw.

• Do not use saws in a bench mounted configuration.

ADJUSTMENTS

OILER ADJUSTMENT

The built–in lubricator has been properly adjusted at the

factory to produce the correct amount of lubrication for the

tool. Insufficient lubrication can result from clogged oiler

felts within the lubricator. To replace the felts, proceed as

follows:

1. Remove the Drain Plug and pour the oil from the oil

chamber.

2. With a thin blade screwdriver, remove the Oiler

Adjusting Screw.

3. Using tweezers or a bent piece of wire, remove the

Oiler Felts and install a new set.

4. Replace the Oiler Adjusting Screw, installing it slightly

below flush, and replace the wool.

5. Replenish the oil supply and install the Drain Plug.

PLACING TOOL IN SERVICE

LUBRICATION

Ingersoll–Rand No. 50 Ingersoll–Rand No. 28

Always use an air line lubricator with these tools.

We recommend the following Filter–Lubricator–Regulator

Unit:

International – No. FRL30–C6–A29

Where a permanent lubricator cannot be installed, inject

3 cc of Ingersoll–Rand No. 50 Oil into the air inlet before

attaching the hose. Remove the Drain Plug from the Motor

Housing and fill the chamber. After each eight hours of

operation, replenish the oil supply.

Whenever the Saw is disassembled for maintenance or

repair, work 3 to 4 cc of Ingersoll–Rand No. 28 Grease

around the Arbor Gear and Rear Arbor Bearing.

After each forty–eight hours of operation, inject five or

six strokes of Ingersoll–Rand No. 28 Grease into the Grease

Fitting.

After each year of service, clean all grease from the

gearing and replace it with 3 to 4 cc of fresh

Ingersoll–Rand No. 28 Grease.

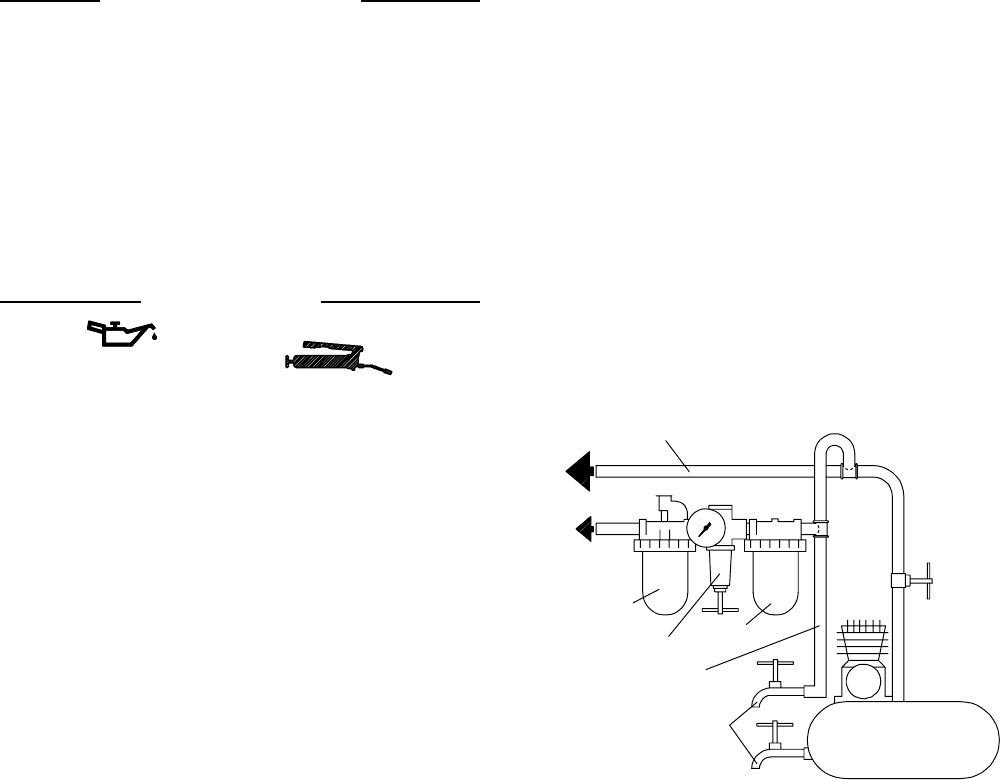

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

FILTER

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

COMPRESSOR

(Dwg. TPD905–1)