4 45527801_ed1

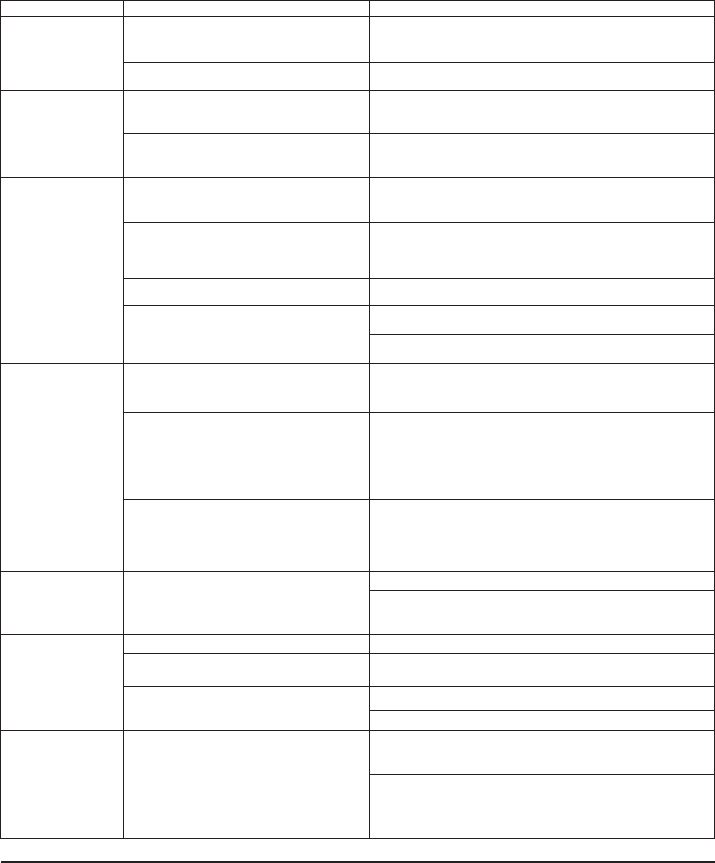

Trouble Probable Cause Solution

Screwdriver runs in

one direction but

not the other

Are wire leads in good condition

and properly soldered?

Defective solder connections. Resolder and rewire if necessary.

Does Reverse Switch operate properly? Defective Reverse Switch (9). Replace it.

Bit does not rotate

but motor hums.

When gears are removed, will the motor

rotate?

Armature (31) is in contact with the magnets. Replace the

motor.

Foreign material in the motor. Clean the motor.

1.

2.

Is planetary gearing smooth when bit is

rotated by hand?

Bearing has failed. Replace the Spindle Assembly (40).

Gears are worn or damaged. Replace any defective gearing.

Clutch Assembly is worn. Replace damaged or worn parts.

1.

2.

3.

Shuto brake

malfunctions more

than one index of

the Clutch.

Does the speed of the Bit exceed rated speed

by more than 100 rpm?

Motor magnet is demagnetized. Replace the motor.

Is Brake Switch functioning? (Does it click

when button is depressed and does it test

correctly with an ohmmeter?)

Defective Brake Switch (15). Replace the Brake Switch.

Does Pushrod (35 or 46) function properly? Bent or worn Pushrod (35 or 46). Replace it.1.

Does Cam (43) function properly?

Cam is worn and not providing adequate lift.

Replace the Cam.

1.

Controller malfunctioning or defective.

Repair or replace. See Controller Service Manual.

Tool makes

abnormal sounds

when the motor is

running.

Is there looseness at the assembly points?

Screws (2) are loose. Tighten all Screws.

Clutch Housing is loose. Tighten the Clutch Housing to the

proper torque.

1.

2.

After removing the gear train does motor

sound normal when running?

Armature (31) is in contact with the Magnet. Replace the

motor.

Foreign material has gotten into the motor. Clean or replace

the motor.

Ball Bearings are defective. Replace the Motor.

Armature is defective. Replace the Motor.

1.

2.

3.

4.

Is the gear train properly lubricated?

No grease on the gear train.

Apply a thin lm of the recommended grease to the gear train.

Spindle Bearing has failed.

Replace the Spindle Assembly (40).

Gears are worn or dirty. Clean or replace the Gears.

1.

2.

Tool generates

abnormal heat when

operating.

After removing the gear train, does tool cool

down and motor run normally?

Motor is defective. Replace the motor.

Planetary gears and the Clutch require lubrication.

Lubricate the Clutch and gear train with the recommended

grease. Note: Do not apply tooI much or too little grease.

Tool outputs high

torque.

Is the shuto brake functioning properly? Refer to Problem No. 4 to check shuto brake malfunctions.

Is Clutch properly lubricated?

No lubrication on the Clutch Components. Lubricate the Clutch

with recommended Grease.

Is there wear on face of cam guide where it

contacts Spindle Assembly (40)?

Cam guide is worn. Replace the Bit Holder Assembly.

Clutch Spring (51) is damaged. Replace Spring.

Tool outputs low

torque.

Is the Clutch Housing joint tight?

Loose joint between the Gear Case (37) and Clutch

Housing (53).

Tighten the joint iwth a torque wrench to specied torque.

Cam (43) is worn. Replace the Cam.

Clutch Spring (51) is damaged. Replace the Clutch Spring.

Cam guide is damaged. Replace the Bit Holder

Assembly (48).

1.

2.

3.

Related Documentation

For additional information refer to:

Product Safety Information Manual 16602963.

Product Information Manual 45527702.

Parts Information Manual 45527777.

Manuals can be downloaded from www.irtools.com.