25

MAINTENANCE SECTION

f. Press the Bevel Pinion Driver Bearing (33) onto

the gear head end of the Bevel Pinion Driver (31).

g. Install the Internal Gear (32) over the gear head

end of the Bevel Pinion Driver, making sure the

splines of the Internal Gear mesh with the Planet

Gear teeth.

h. Install the Thrust Spacer (38) over the threaded

end of the Bevel Pinion Driver.

i. Press the Bevel Pinion Bearing (39) onto the

Bevel Pinion Driver.

If the Pinion (40) needs to be replaced, replace

both the Pinion and Bevel Gear. They are a

matched set and cannot be matched with other

Bevel Gears.

j. Check the Pinion for worn or broken teeth.

k. Screw the Pinion onto the threaded Bevel Pinion

Driver and tighten to 14 to 19 ft–lb (19 to 26 Nm)

torque.

For GRG15A, GRG15M or GRS15A Models:

a. Press the Bevel Pinion Bearing (39) over the

threaded end and onto the Bevel Pinion

Driver (31).

If the Pinion (40) needs to be replaced, replace

both the Pinion and the Bevel Gear. They are a

matched set and cannot be matched with other

Bevel Gears.

b. Check the Pinion for worn or broken teeth.

c. Screw the Pinion onto the Bevel Pinion Driver and

tighten to 14 to 19 ft–lb (19 to 26 Nm) torque.

d. Coat the inner surface of the Arbor Coupling (42),

the spline of the Rotor (26) and the spline of the

Bevel Pinion Driver with 3 to 4 cc of

IRAX No. 68–1LB Grease. Do not substitute

any other grease.

e. Install the Arbor Coupling onto the spline end of

the Bevel Pinion Driver.

f. Install the Thrust Spacer (38) over the Arbor

Coupling (42) until it is against the Bevel Pinion

Bearing.

2. Grasp the Angle Arbor Housing (43) horizontally in

leather–covered or copper–covered vise jaws.

3. Slide the assembled Bevel Pinion Driver into the

Angle Arbor Housing.

4. For GRG15A, GRG15M or GRS15A Models, next

install the Motor Spacer (41).

Make sure the Throttle Lever Assembly (17)

mounting boss on the Throttle Handle (1) aligns

with the closed, upper portion of the Angle Arbor

Housing.

For GRP15A–02P–7 Models, make sure the spline

on the Rotor (26) properly engages the spline in the

Rotor Pinion (35).

5. Slide the assembled Throttle Handle into the Angle

Arbor Housing.

6. Clean the Coupling Nut (21) threads and carefully

apply a uniform coat of Vibra–Tite** VC3 No. 205

to at least the first three threads. Allow the

Vibra–Tite to cure for ten to twenty minutes before

assembly.

Do not exceed 52.5 ft–lb (71.2 Nm) torque. The

motor may be damaged if this torque is exceeded.

7. Using the No. 49843–147 Coupling Nut Wrench,

install the Coupling Nut and tighten it between 48 to

52.5 ft–lb (64 to 71 Nm) torque.

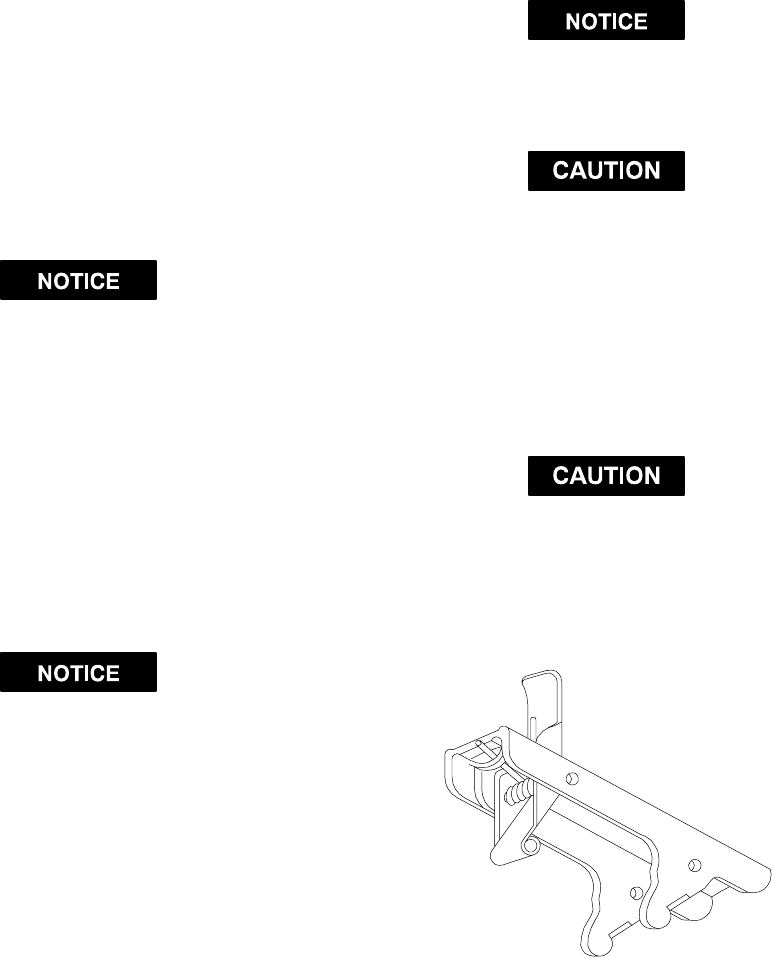

Assembly of the Throttle Lever and Inlet

(Dwg. TPD662)

Locking Lever Assembly

1. Assemble the Throttle Lever Assembly (17) as

illustrated.

2. Align the holes in the Throttle Lever Assembly with

the slots in the Throttle Handle. Using a soft hammer,

tap the Throttle Lever Pin (16) into the Throttle Lever

Assembly until it slightly protrudes from the opposite

end. File off any sharp edges. Operate the

mechanism to assure operation.

3. Grasp the flats of the Throttle Handle Assembly (1) in

leather–covered or copper–covered vise jaws, air inlet

up.

** Registered trademark of N.D. Industries