6. Place it betweenthe fingers of both blade

guides and onto both wheels. Position next to

both wheel flanges. Make sure teeth point

down toward the table.

7.

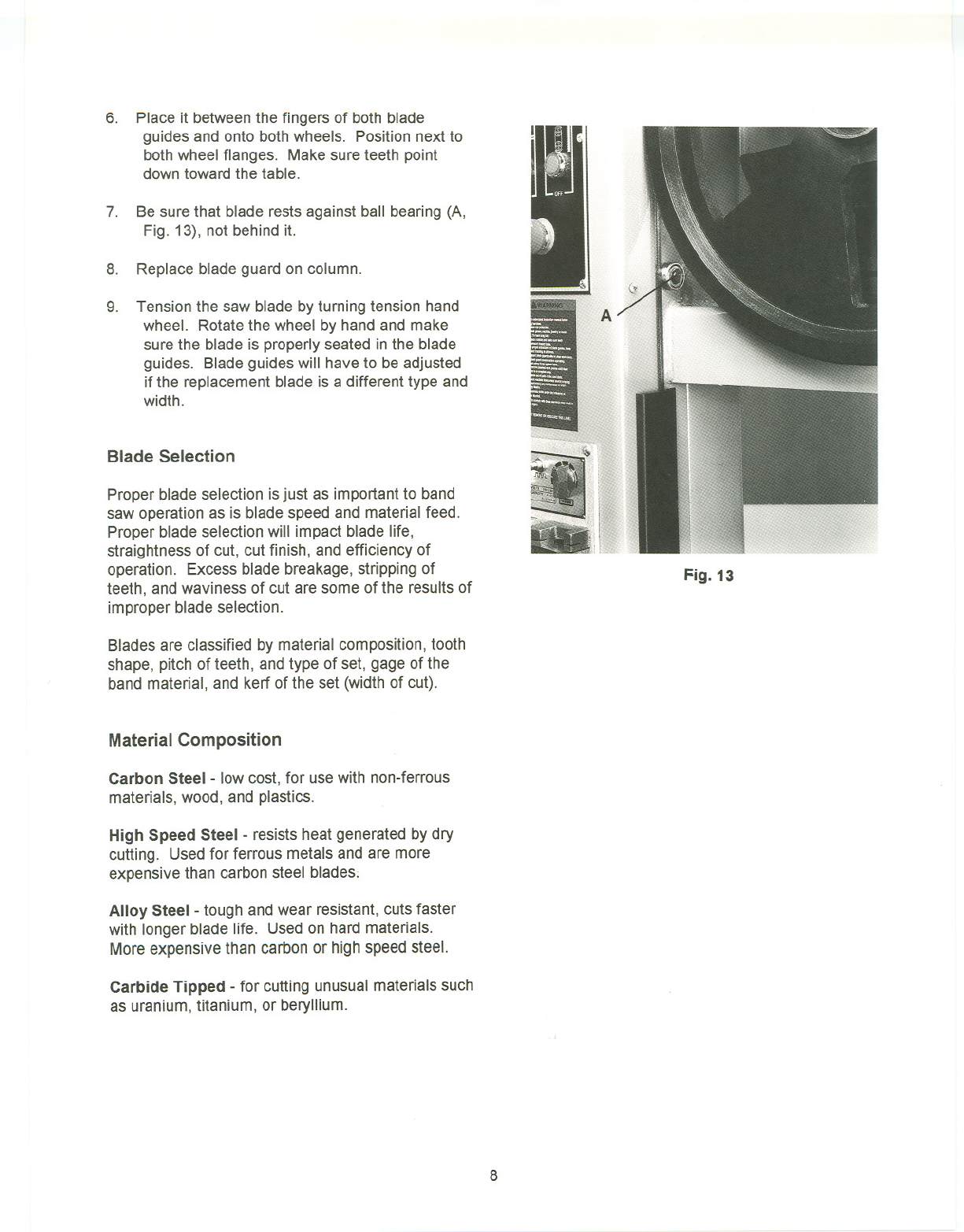

Be sure that blade rests against ball bearing (A,

Fig. 13), not behind it.

8. Replace blade guard on column.

9. Tension the saw blade by turning tension hand

wheel. Rotate the wheel by hand and make

sure the blade is properly seated in the blade

guides. Blade guides will have to be adjusted

if the replacement blade is a different type and

width.

Blade Selection

Proper blade selection isjust as important to band

saw operation as is blade speed and material feed.

Proper blade selection will impact blade life,

straightness of cut, cut finish, and efficiency of

operation. Excess blade breakage, stripping of

teeth, and waviness of cut are some of the results of

improper blade selection.

Blades are classified by material composition, tooth

shape, pitch of teeth, and type of set, gage of the

band material, and kerf of the set (width of cut).

Material Composition

Carbon Steel - low cost, for use with non-ferrous

materials, wood, and plastics.

High Speed Steel - resists heat generated by dry

cutting. Used for ferrous metals and are more

expensive than carbon steel blades;

Alloy Steel - tough and wear resistant, cuts faster

with longer blade life. Used on hard materials.

More expensive than carbon or high speed steel.

Carbide Tipped - for cutting unusual materials such

as uranium, titanium, or beryllium.

Fig. 13

8