9

8.1 Operating lever

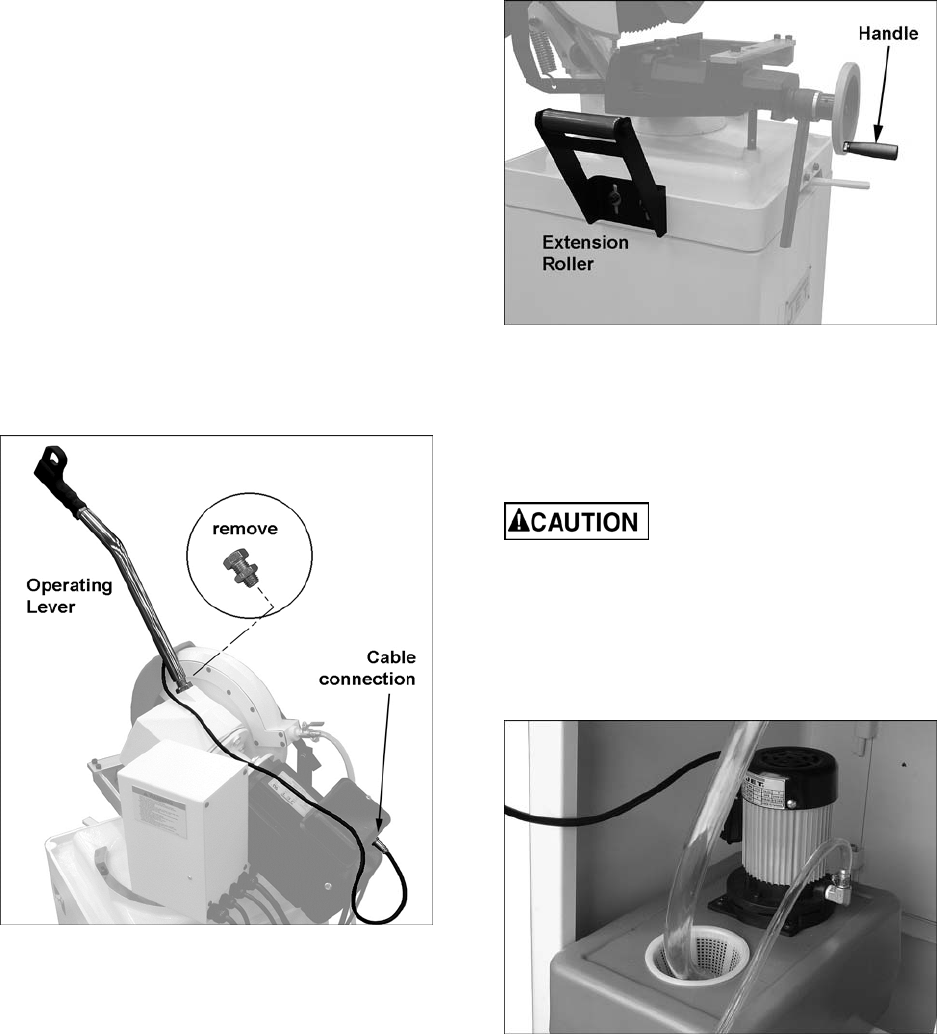

Refer to Figure 3.

1. Remove the hex nut and screw from the hole

at the front of the saw head (Figure 4). These

fasteners will not be used again unless the

machine needs to be transported in the future.

2. Insert the operating lever into the threaded fill

hole. Rotate it a good distance into the hole,

and make sure the final orientation of the

handle grip is in a comfortable position for the

operator, as shown in Figure 3.

3. Secure the operating lever by tightening the

hex nut against the saw head.

4. Push the two-pin cable connector into the

receptacle sleeve on the junction box of the

motor, and tighten the knurled ring to secure.

Figure 3

8.2 Handle

Refer to Figure 4.

Screw the handle into the handwheel and tighten

with the nut, using a 12mm wrench.

8.3 Exension roller

Refer to Figure 4.

Mount the extension roller to the side with the

existing socket head cap screws, using a 6mm hex

key.

Slots make the roller assembly adjustable for

height. Place a straight edge across the clamp

table and the extension roller to achieve alignment.

Figure 4

8.4 Coolant tank

Refer to Figure 5.

Direct the lower end of the drain hose into the

basket of the coolant tank, as shown.

Fill the tank with coolant

before operating the coolant pump. Failure to

do so may damage the pump.

Adjust the valve on the coolant fitting atop the

blade housing, to achieve desired flow. When the

coolant switch is in the ON position, flow starts

when the drive motor is started. Turning off the

coolant switch stops coolant flow.

Figure 5

8.5 Splash plates

Refer to Figure 6.

The plates deflect expended coolant and swarf

coming off the blade, into the encircling channel of

the base. The coolant drains back into the tank,

while the swarf is easily cleaned from the channel.

Mount the two plates to the front and rear of the

base, using the existing screws in the base and a

6mm hex key. Slots allow height adjustment.