11

Operation

A bench grinder is designed for hand-grinding

operations such as sharpening chisels,

screwdrivers, drill bits, removing excess metal,

and smoothing metal surfaces.

A Medium Grain Abrasive Grinding Wheel is

suitable for rough grinding where a considerable

amount of metal must be removed or when

obtaining a smooth finish is not important.

A Fine Grain Abrasive Grinding Wheel should be

used for sharpening tools of grinding to close

size tolerances because it removes metal more

gradually for precision grinding and gives work a

smooth finish.

Always use approved safety

glasses or face shields! Failure to comply

may cause serious injury!

Switch

The switch is located on the front of the grinder

near the bottom. To turn the tool on, depress the

rocker switch at the top near the word ON. To

turn the tool off, depress the bottom part of the

rocker switch near the word OFF.

Precautions

Before starting the grinder, turn the wheels by

hand making sure they are clear of obstructions

and that they turn freely. The tool rests and

spark guards should not touch the wheel.

Turn on the grinder and allow it to reach full

running speed before starting to grind.

Keep a steady, moderate pressure on the

workpiece and keep it moving at an even pace

for smooth grinding. Pressing too hard

overheats the motor and prematurely wears

down the grinding wheels. Note the original

bevel angle on the item to be sharpened and try

to maintain the same shape. The grinding wheel

should rotate into the object being sharpened.

Keep a tray filled with water and dip your work

into in regularly to prevent overheating.

Overheating can weaken metals.

Do not use the side of the grinding wheel; this

puts dangerous stress on the wheel.

When the wheel becomes loaded of dull, use an

approved grinding wheel dresser and dress the

wheel face.

Keep the tool rest and spark guard to within

1/16" of the grinding wheel. See the Adjustment

section to adjust.

Adjustments

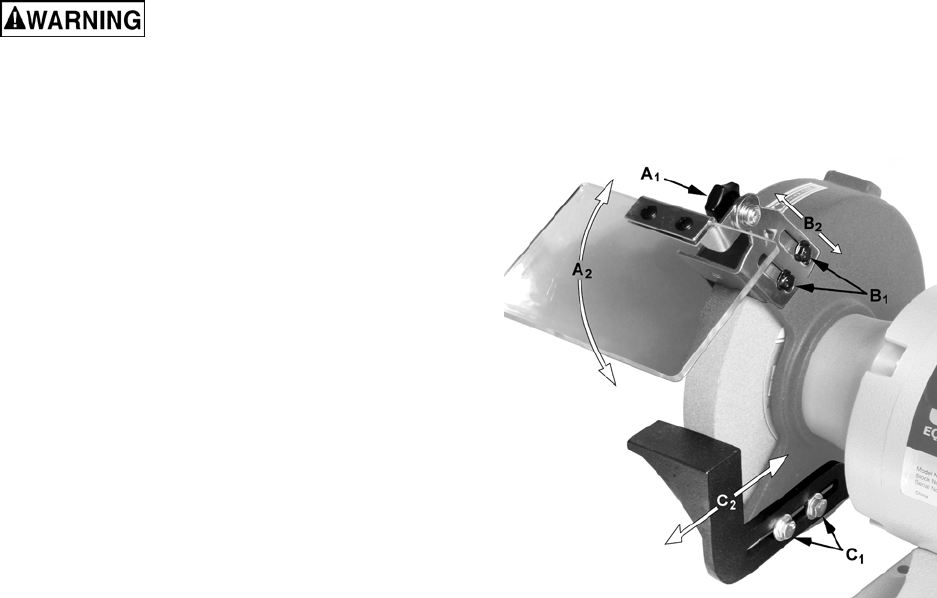

Eye Shield Tilt Adjustment

1. Loosen lock knob (A

1

, Fig. 3).

2. Adjust eye shield to the desired tilt

angle (A

2

, Fig. 3).

Spark Guard

As the wheel wears down, the spark guards

must be re-adjusted to maintain a 1/16"

distance.

To adjust:

1. Loosen two hex cap screws (B

1

, Fig. 3) with

a 10mm wrench.

2. Slide the spark guard (B

2

, Fig. 3) to 1/16"

distance from the grinding wheel surface.

3. Tighten screw (B

1

, Fig. 3).

Figure 3

Tool Rest

As the wheel wears down, the tool rests must be

re-adjusted to maintain a 1/16" distance.

1. Loosen two hex cap screws (C

1

, Fig. 3) with

a 12mm wrench.

2. Slide the tool rest (C

2

, Fig. 3) to a distance

of 1/16" from the grinding wheel.

3. Tighten screws (C

1

, Fig. 3).