9

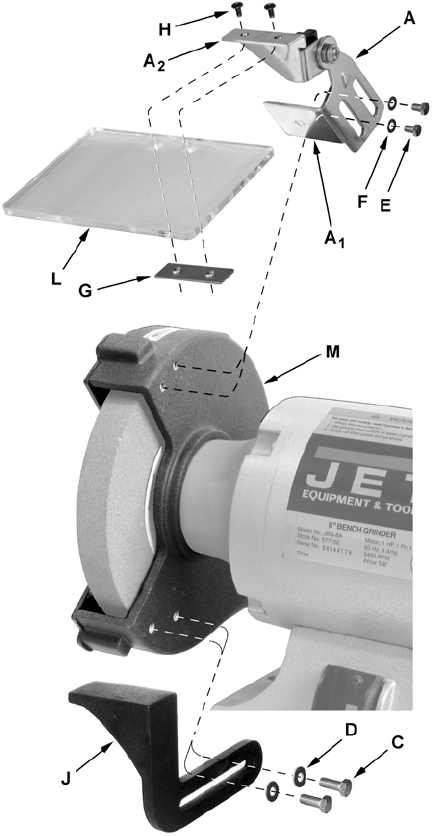

Installing the Spark Guard and Eye

Shield Mounting Brackets

Refer to Figure 2:

Parts needed:

2 Spark Guard and Eye Shield Brackets

assembled from previous page

4 1/4” x 3/8” Hex Cap Screws (E)

4 1/4" Flat Washers (F)

1. Install the left spark guard and mounting

bracket (A) to the left wheel housing (M) with

two 1/4” x 3/8” hex cap screws (E) and two 1/4"

flat washers (F).

The spark guards (A

1

) should be adjusted to

within 1/16" of the grinding wheel surface or

other accessory being used.

2. Install the right spark guard and mounting

bracket in the same manner.

Note: As the wheel wears down, the spark guards

must be re-adjusted to maintain the 1/16" distance.

Tool Rests

Refer to Figure 2:

Parts needed:

2 Tool Rest Left (J) and Right (not shown)

4 5/16" x 3/4" Hex Cap Screws (C)

4 5/16" Flat Washers (D)

Note: There is a left and a right tool rest. Refer to

Figure 1 to ensure that you install them correctly.

1. Install the left tool rest (J) by threading two

5/16" x 3/4" hex cap screws (C) through two

5/16" flat washers (D) and the tool rest (J) into

the wheel housing (M).

The tool rests should be adjusted to within

1/16" of the grinding wheel or other accessories

being used. As the wheel wears down, the tool

rest must be re-adjusted to maintain a 1/16"

clearance.

2. Install the right tool rest in the same manner.

Eye Shields

Refer to Figure 2.

Parts needed:

4 3/16” x 3/8” Pan Head Screws (H)

2 Eye Shields (L)

2 Eye Shield Bracket Plates (G)

The eye shields (L) are identical and will fit on

either side of the grinder.

Figure 2

To install eye shields (refer to Figure 2):

Insert two 3/16” x 3/8” pan head screws (H) through

the mounting plate (A

2

), eye shield (C), and bracket

plate (G) containing threaded mounting holes.

Tighten the screws (H).

Mounting the Grinder

To prevent the grinder from moving during

operation, it should be securely mounted to a work

surface or grinder stand.

1. Align the mounting holes on the grinder with

predrilled holes in a bench or grinder stand.

2. Insert bolts through the holes and tighten, using

washers and nuts (not included).