14

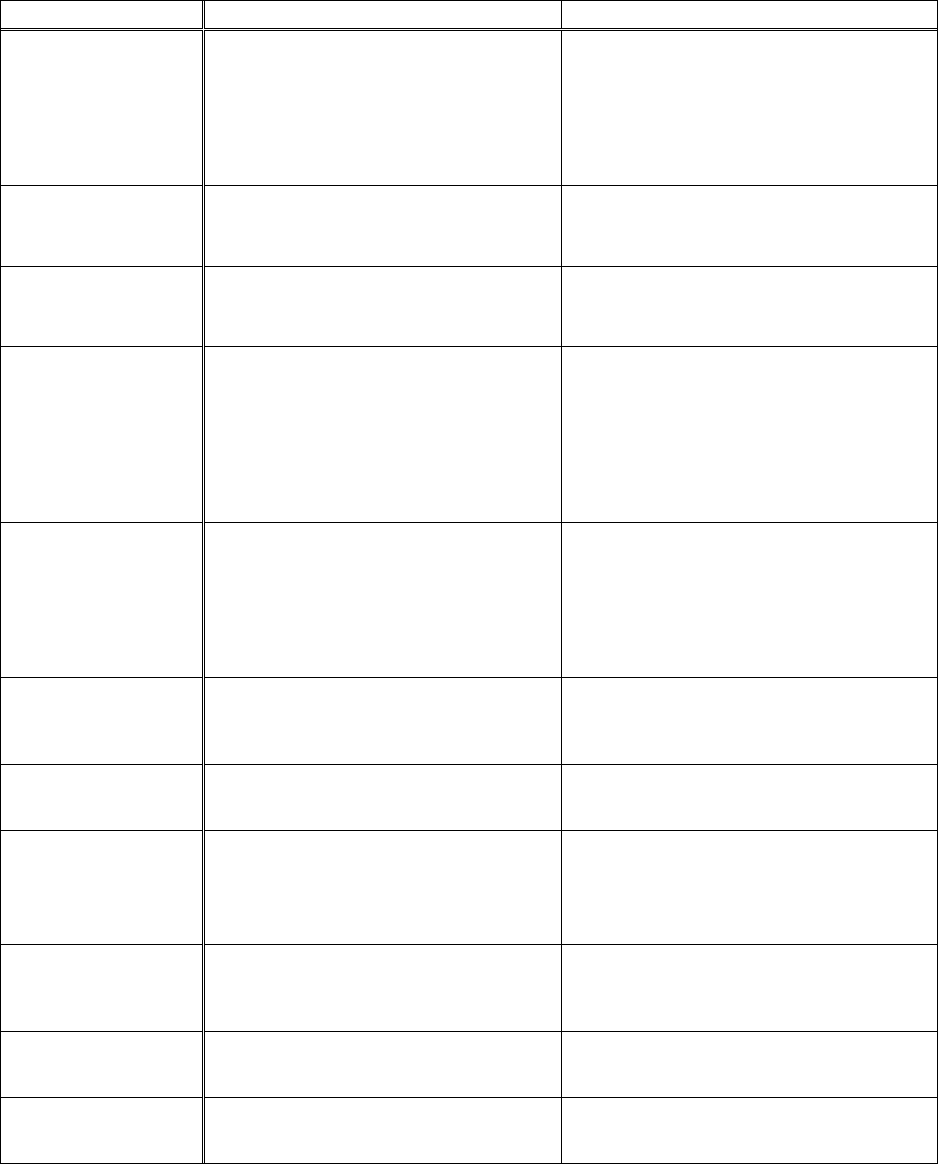

Troubleshooting

Trouble Probable Cause Remedy

Drill press will not

start.

1. Drill press unplugged from wall or

motor.

2. Fuse blown or circuit breaker

tripped.

3. Cord damaged.

4. Starting capacitor bad.

1. Check all plug connections.

2. Replace fuse or reset circuit breaker.

3. Replace cord.

4. Replace starting capacitor.

Drill press does not

come up to speed.

1. Extension cord too light or too long.

2. Low current.

1. Replace with adequate size and length

cord.

2. Contact a qualified electrician.

Drill Press vibrates

excessively.

1. Stand on uneven surface.

2. Bad belt(s).

1. Adjust stand so that it rests evenly on

the floor.

2. Replace belts.

Noisy Operation.

1. Incorrect belt tension.

2. Dry spindle.

3. Loose spindle pulley.

4. Loose motor pulley.

1. Adjust belt tension. See Chang-ing

Spindle Speeds on page 12.

2. Lubricate spindle. See Lubrication on

page 15.

3. Check tightness of retaining nut on

pulley and tighten if necessary.

4. Tighten set screws in pulleys.

Workpiece Burns.

1. Incorrect Speed.

2. Chips not clearing from hole or bit.

3. Dull drill bit.

4. Feeding too slowly.

1. Change to appropriate speed – see

speed and pulley chart on page 13.

2. Retract drill bit frequently to remove

chips.

3. Resharpen, or replace drill bit.

4. Increase feed rate.

Drill bit wanders.

1. Bit sharpened incorrectly.

2. Bent drill bit.

3. Bit or chuck not installed properly.

1. Resharpen bit correctly.

2. Replace drill bit.

3. Reinstall the chuck, or bit properly.

Wood splinters on the

underside.

1. No backing board used.

1. Place a scrap board underneath the

workpiece to prevent splintering.

Drill bit binds in

workpiece.

1. Workpiece pinching the bit.

2. Excessive feed rate.

3. Chuck jaws not tight.

4. Improper belt tension.

1. Support or clamp workpiece.

2. Decrease feed rate.

3. Tighten chuck jaws.

4. Increase belt tension (page 12).

Excessive drill bit run

out, or wobble.

1. Bent drill bit.

2. Worn spindle bearings.

3. Bit or chuck not properly installed.

1. Replace drill bit.

2. Replace spindle bearings.

3. Reinstall the bit, or chuck properly.

Quill returns too slow,

or too fast.

1. Spring has improper tension.

1. Adjust “Return Spring Tension,” page

14.

Chuck or arbor do not

stay in place.

1. Dirt, grease, etc on arbor, chuck, or

spindle.

1. Clean all mating surfaces thoroughly

with a cleaner degreaser.