11

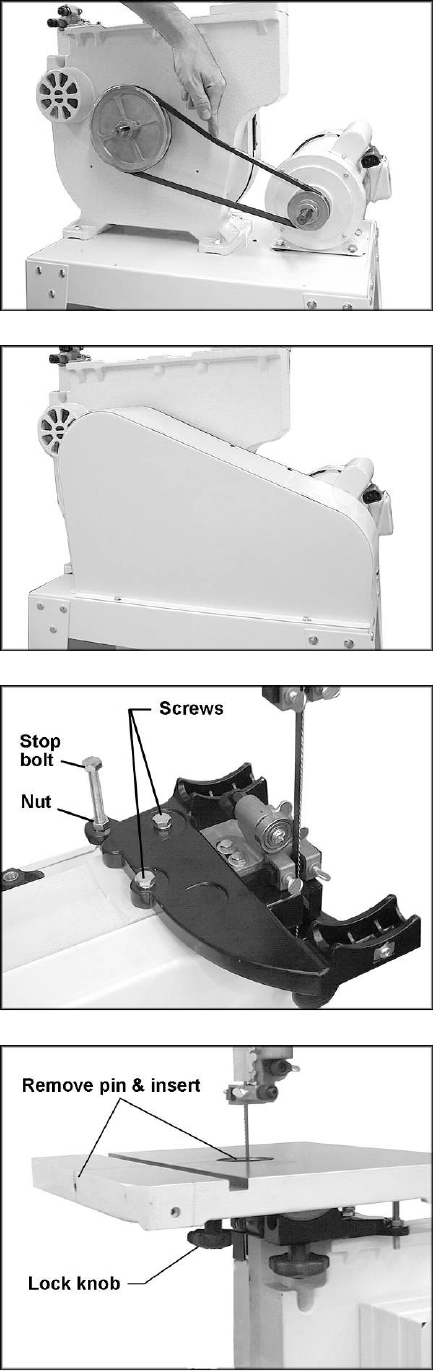

9. Place

v

-belt over both pulle

y

s. See Fi

g

ure 8.

10. Tension v-belt by moving motor away from

the saw body and tighten the motor mount

nuts. (Do not over-tighten motor mount

bolts. Tighten just enough to tension belt.)

Belt is properly tensioned when finger

pressure between the two pulleys (Figure 8)

causes approximately 1/2” deflection.

11. Place pulley cover over both pulleys and

fasten to stand using three pan head

screws, six washers, and three hex nuts, as

shown in item D, page 7. See Figure 9.

12. Attach trunnion support bracket to saw body

with two hex cap screws and two lock

washers as shown in item E, page 7. See

Figure 10.

13. Thread nut onto table stop bolt (Figure 10)

and attach to trunnion support bracket.

14. To mount table, remove table insert and

table pin (see Figure 11). Orient the table so

that the saw blade will pass through the slot

in the table and into the center opening.

Continue holding up the table, and turn the

table so the two screws that are hanging

vertically from below the table will slide into

the holes on the trunnion support bracket.

Lower the table. The screws should now

protrude below the trunnion support bracket

- attach lock knobs to the ends of these

screws. See Figure 11.

15. Re-install table insert and table pin.

16. Join motor plug to switch plug.

17. Transportation and handling may have

caused some fasteners to loosen. Before

operating, check all screws, bolts, and nuts

to make sure they are snug. Operate

machine only after reading the entire

manual including blade tracking, blade

guide adjustments, and safety rules.

18. Exposed metal surfaces, such as the table,

have been given a protective coating. This

should be cleaned with a soft cloth and

solvent, such as kerosene. Do not use

acetone, gasoline, or lacquer thinner. Do not

use an abrasive pad, and do not get

solvents on plastic parts.

Proceed to “Grounding Instructions” on page 14.

Figure 8

Figure 9

Figure 10

Figure 11