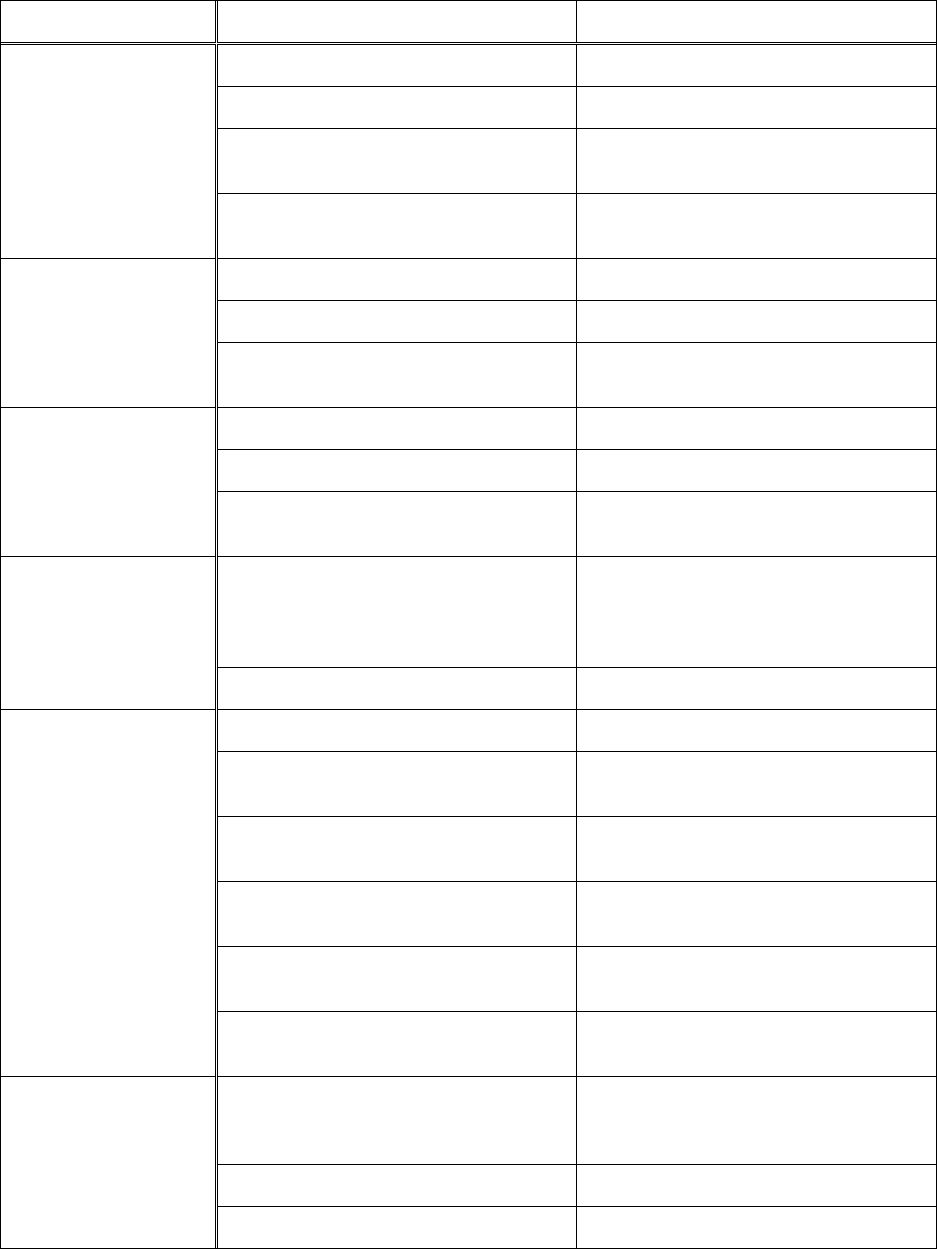

16

Troubleshooting

Trouble Probable Cause Remedy

No incoming power. Check plug connection.

Blown electrical panel fuses. Replace fuses.

Thermal overload has tripped.

Release run button and wait several

minutes for overload to reset itself.

Motor will not start, or

stops suddenly.

Defective motor, switch, power cable,

or plug.

Qualified electrician/service personnel

should inspect these items.

Motor is overheating. Check that motor air intakes are clear.

Downfeed pressure is too fast. Reduce downfeed pressure.

Overload trips

frequently.

Motor is faulty.

Motor should be inspected by

qualified electrician/service personnel.

Stand is on uneven surface. Adjust stand for even support.

Saw blade has cracks. Replace blade immediately.

Band Saw vibrates

excessively.

Too heavy a cut.

Reduce downfeed pressure and blade

speed.

Setting of the miter stops is not

correct.

Adjust the stops to correct positions.

See page 12. Use an adjustable

square or protractor to check angle

settings.

Miter cuts not

accurate.

Blade guides not set correctly. See page 11 for proper adjustment.

Downfeed pressure too great. Decrease downfeed pressure.

90° angle stop is not set correctly.

Adjust stop until blade is square with

vise.

Incorrect blade toothing in relation to

workpiece.

Consult the cutting parameters (blade

teeth, cutting speed) in Figure 17.

Incorrect adjustment of bearing

guides and guide assembly.

Re-adjust these. See page 11.

Workpiece incorrectly positioned in

vise.

Check positioning and clamping in the

vise.

Cuts not square.

Poor blade tension.

Check and correct if needed. See

page 12.

Blade is dull, or its parameters are not

right for thickness of piece being cut.

Use proper blade tooth configuration

for that particular workpiece. See

chart, Figure 17.

Downfeed pressure too great. Reduce downfeed pressure.

Finished surface of

workpiece is rough,

unsatisfactory.

Blade tension too low. Increase blade tension.