Operator’s Manual 27

MAINTENANCE

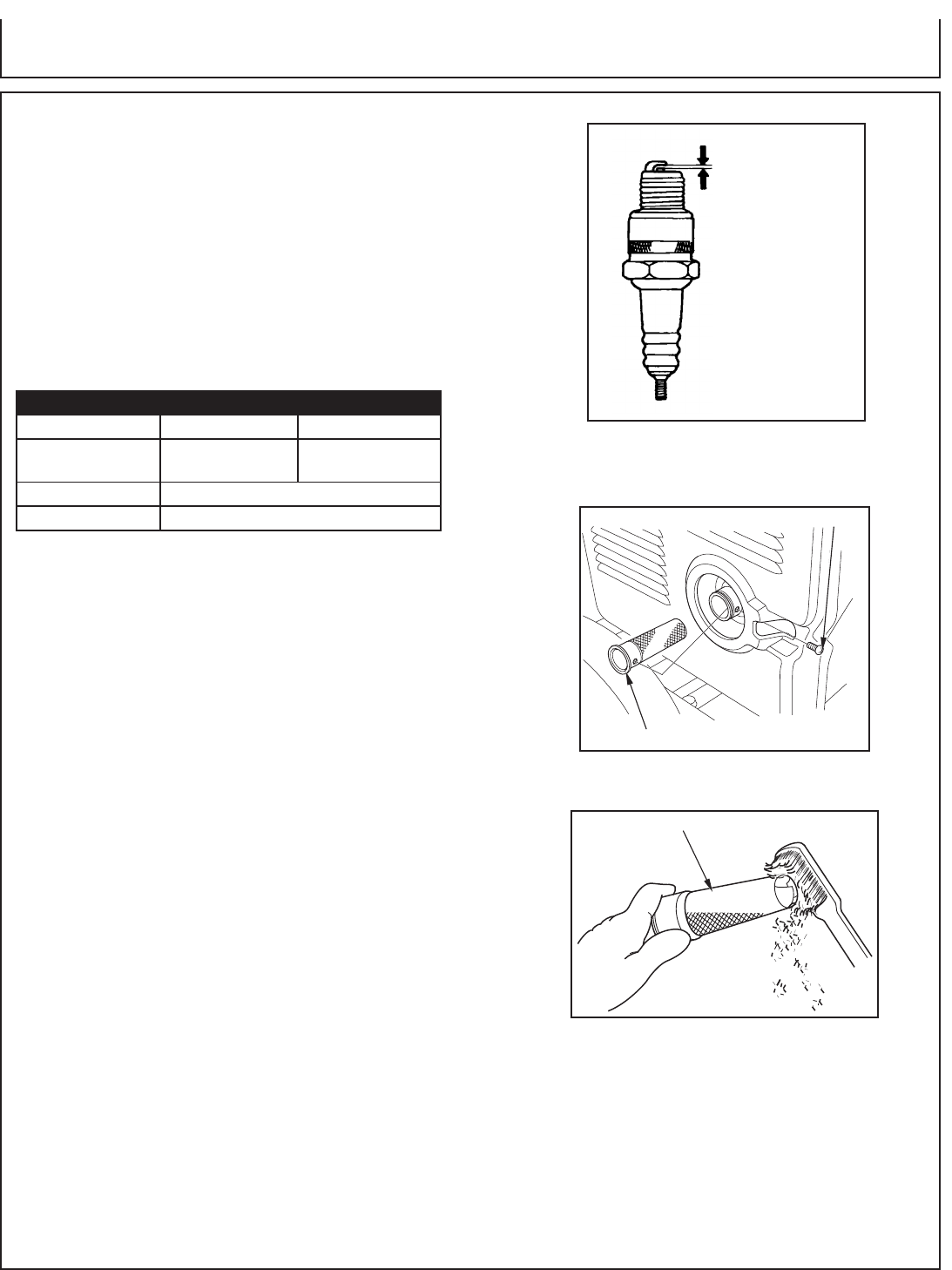

CLEANING AND GAPPING SPARK PLUG:

If the plug is contaminated with carbon, remove it using a

plug cleaner or wire brush.

Check the spark plug gap and reset it if necessary. The spark

plug gaps are listed below. To change the gap, bend the side-

electrode only, using a spark plug tool. (Fig. 9)

Install and tighten the spark plug. Connect the spark plug

lead.

Recommended Spark Plug:

SPARK ARRESTOR:

If the generator has been running, the mufer will be very

hot. Allow it to cool before proceeding.

NOTE: Remove and clean spark arrester every 100 hours

or as necessary.

NOTE: Product users on United States forest service land, and

in some states, must comply with re

prevention regulations.

Clean the spark arrester as follows: (Fig. 10 and 11)

1. Loosen the screw by the exhaust port of the mufer and

remove the spark arrester.

2. Use a brush to remove carbon deposits from the spark

arrester screen. Inspect the screen for breaks or tears and

replace it if necessary.

3. Install the spark arrester in the reverse order of removal.

Spark arrestors are available from your local John Deere

Customer Service. Other user requirements may apply, check

with your Federal, State or local authorities.

Service

Spark Plug Gap

(See recommendations)

SPARK ARRESTER SCREEN

SPARK ASSESTER

SCREW

(Fig. 9)

(Fig. 11)

(Fig. 10)

Engine Subaru Honda

Spark Plug NGK BR-6HS NGK BPR6ES

Spark Plug Gap 0.6 - 0.7 mm

(0.02-0.03 in.)

0.7 - 0.8 mm

(0.03 in.)

Torque - New 8.7-10.9 ft-lb

Torque - Retighten 16.6-19.5 ft-lb