12

Section 4: Maintenance and Lubrication

PR1560 & PR1572 Powered Rakes 314-164M

Land Pride

7/14/08

Table of Contents

Maintenance

!

CAUTION

BEFORE any maintenance is performed, lower the Powered

Rake to the ground, stop tractor engine and remove key. DO

NOT attempt to make maintenance adjustments while tractor is

running.

Storage

At the end of the working season or when the Powered

Rake will not be used for a long period, it is good practice

to clean off any dirt or grease that may have accumulated

on any of the moving parts.

Check the roller studs or bars for wear and replace the

roller and/or studs if necessary.

Inspect the Powered Rake for loose, damaged or worn

parts and adjust or replace if needed.

Lubricate as noted in “Lubrication” on page 14.

Repaint parts where paint is worn or scratched to prevent

rust.

Drain gearbox and chain case oil. Drain oil in gearbox by

removing the bottom drain plug. Drain oil in chain case by

removing bottom cover (#2) Figure 5-2. Be sure to refill

gearbox and chain case at this time.

Apply a light coat of grease to any exposed hydraulic

cylinder rod.

Store Powered Rake in a clean, dry place.

Drive Chain Maintenance

The operator should check periodically to make sure that

the drive chain is tight. If adjustment is needed refer to

“Drive Chain Adjustment” on page 11.

Chain Case Skid Shoe Replacement

Chain Case Skid Shoe Replacement

Figure 5-1

IMPORTANT: Proper servicing and adjustment is the

key to the long life of any machine. With careful and

systematic inspection of the Powered Rake, costly

maintenance, time and repair can be avoided.

IMPORTANT: If chain case skid shoe needs to be

replaced, it is important that the carriage bolt threads

and nuts are coated generously with Sikaflex. This

will insure that there is no oil leakage from chain case.

18013

Sprocket & Drive Chain Replacement

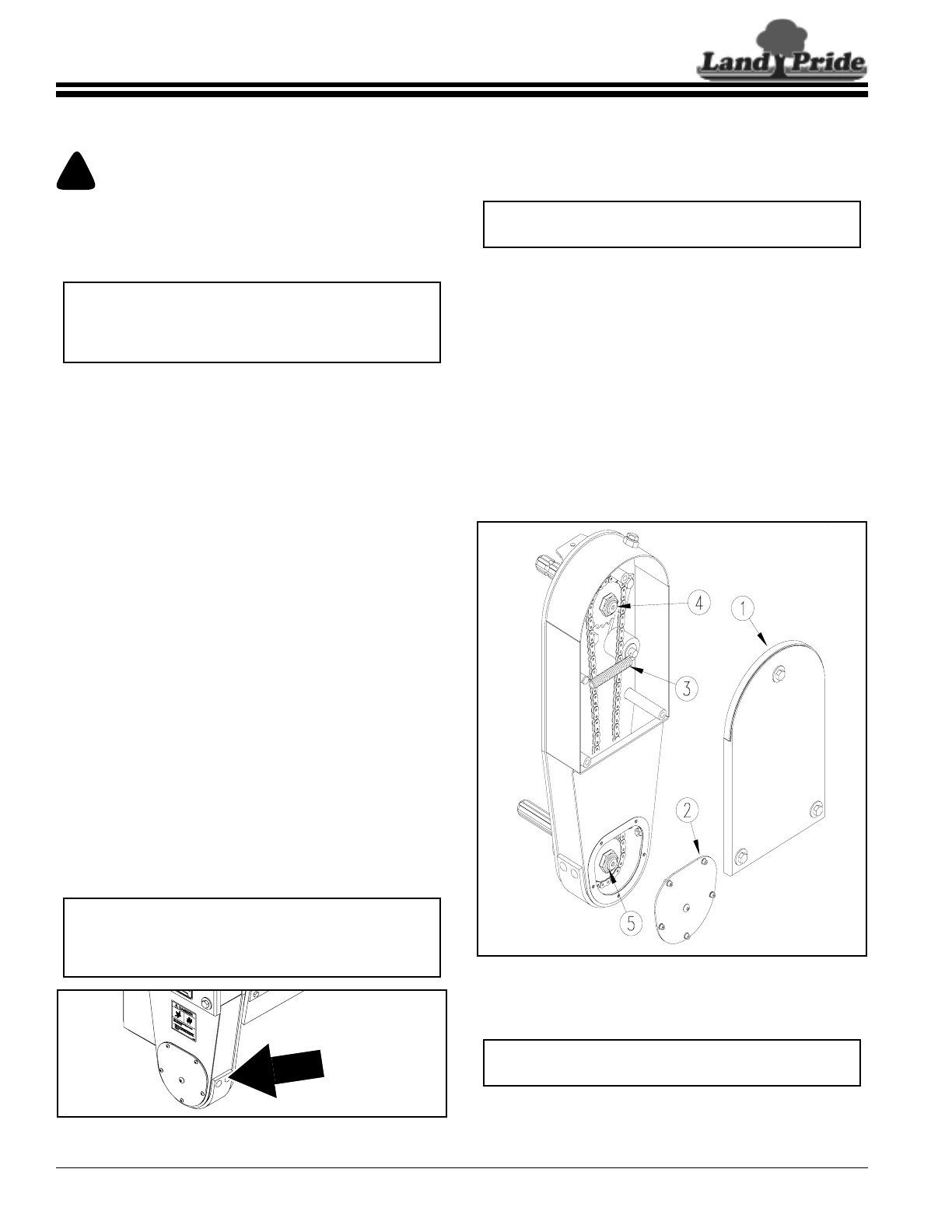

Refer to Figure 5-2:

1. Remove cover plate (#1) and bottom plate (#2).

2. Loosen chain tension by removing spring (#3) from

idler arm.

3. Remove nut (#4) on and/or (#5) sprockets.

4. Remove sprockets and chain.

5. Install new chain and sprockets.

6. Reinstall nut (#4) and (#5).

7. Reinstall spring (#3).

8. Turn the roller several turns and observe the chain to

make sure everything is working properly.

9. Reinstall cover plate (#1) and bottom plate (#2).

10. Check the oil level in the chain case. See

“Lubrication” on page 14.

Sprocket and Drive Chain Replacement

Figure 5-2

2-Plate Slip Clutch

NOTE: Oil in chain case! Be prepared to capture oil

when taking off bottom cover.

18644

NOTE: Before proceeding, secure the clutch firmly

in a vise or other clamping device to prevent injury.

Section 4: Maintenance and Lubrication