Power Feed 10M

[2]

A CLOSER LOOK

FEATURES

MSP4 User Interface Panel

PATENTED DRIVE ROLL SYSTEM — FOUR DRIVE

• Split wire guide provides easy wire loading and maintenance.

•Variety of drive rolls for any application.

• New Twist-Lock™ design.

• High speed gear for most fine wire applications. Low speed gear for

higher torque with Innershield® wire.

• Wire feed speed calibrated to monitor and maintain constant speed.

•Tachometer feedback to monitor and maintain constant speed.

•Brass-to-brass connections and rugged aluminum cast housing provide

reliable performance.

• Angled for ease of payoff and less stress on cables.

• Interchangeable gun bushings for use with a variety of guns.

4-Drive Roll System

Brass Connector

4-Drive Roll

Split Wire Guide

GENERAL STEEL STAINLESS

METAL CORE

ALUMINUM

CV

CC

4043 5356

GMAW

GMAW

GMAW

PULSE (CRISP)

PULSE (SOFT)

STT (NO TAILOUT)

STT II

GMAW

PULSE

PULSE-ON-PULSE

GMAW

PULSE

PULSE-ON-PULSE

GMAW

PULSE

GMAW

GMAW

PULSE

PULSE

PULSE

STT

STT II

CO

2

Ar (MIX)

Ar (MIX)

Ar (MIX)

CO

2, Ar/CO2

CO2, Ar/CO2

Ar

Ar

Ar

Ar

Ar

Ar

Ar/CO

2

Ar/CO2

Ar (Mix)

Ar/He/CO

2

Ar/CO2

Ar/O2

Ar/He/CO2

Ar/He/CO2

Ar/He/CO2

---

94

95

---

109

110

148

149

98

151

152

101

81

82

61

63

66

62

---

109

110

31

33

36

32

34

109

110

41

43

46

42

44

125

126

0.030

0.035 0.035

0.045

0.0300.035

3/64 3/64

0.052

M20240 VM

0.0350.045

1/16 1/16

1/16

0.0450.052

10

11

12

14

109

110

71

72

99

75

76

102

83

84

20

21

22

19

125

126

73

74

100

77

78

103

85

86

24

25

26

28

125

126

STD. CV 5

FCAW STD. CV 6

STICK SOFT (7018) 1

STICK CRISP (6010) 2

TIG TOUCH START 3

GOUGE - - -

9

GMAWPOWER MODE 40

www.lincolnelectric.com

A welding waveform program chart, conveniently located on the Power Feed 10M

Control Box panel, makes standard program selection easy. Delivering an

unprecedented level of arc control, the Power Feed 10M includes a number of preset

welding waveform programs for applications on a variety of materials, including steel,

stainless steel, aluminum, nickel alloys and silicon bronze. Lincoln Electric can add or

design custom waveform programs for those customers requiring targeted solutions

for other materials, joint configurations, welding procedures, shielding gases or other

variables. In addition, Lincoln’s Wave Designer™ software, available upon request,

alllows you to build or customize waveform programs yourself.

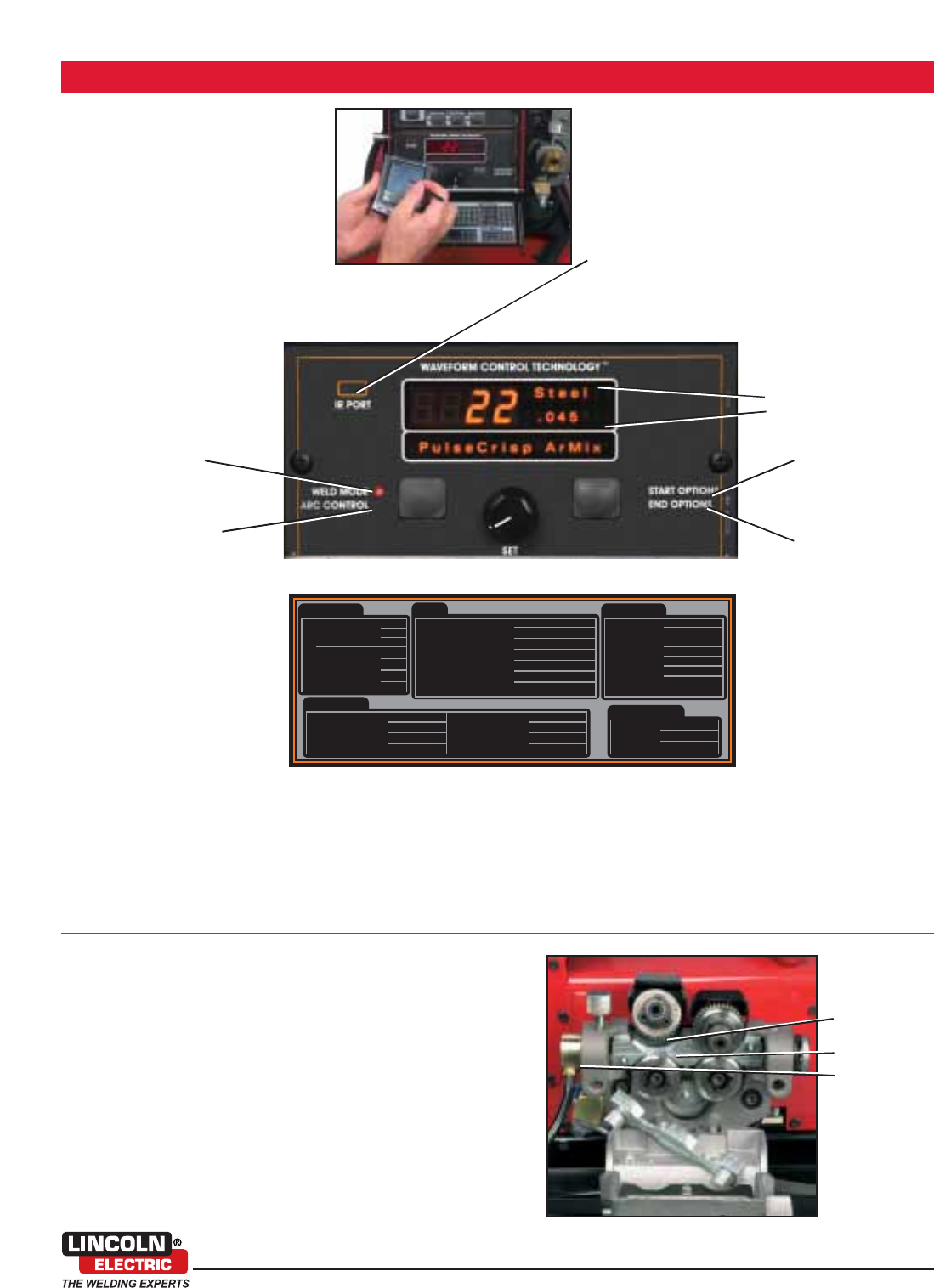

Start Options —

preflow time, run-in

wire feed speed and

start time.

End Options —

crater time, burnback

time, and postflow time.

Weld Mode provides easy

access to the multiple

welding waveform programs

in the Power Wave power

sources.

Arc Control — Also known

as Inductance or Wave

Control. It allows the

operator to vary the arc

characteristics from “soft” to

“crisp” in most weld modes.

Infrared Port (IR)

Wireless machine configuration and diagnostics using a

Palm® OS-based hand-held PDA — no serial cable

needed for connection!

Our Palm® OS-based application configures and

troubleshoots Lincoln welding machines that are

equipped with the IR Port.

Custom set-up to “lock out” operator or limit access to

settings to secure systems, regulate activity and produce

reliable results time after time.

Large, easy-to-read

alpha numeric display.

The New MSP4 User Interface Panel

provides full control of mode selection, arc

control, weld sequence and — through the

IR Port — lockout control.