D-1

MAINTENANCE

D-1

SPREADARC

SAFETY PRECAUTIONS

ELECTRIC SHOCK can kill.

• Turn off power at the power source

disconnect switch before working

inside the equipment.

-----------------------------------------------------------------------

WARNING

PERIODIC MAINTENANCE

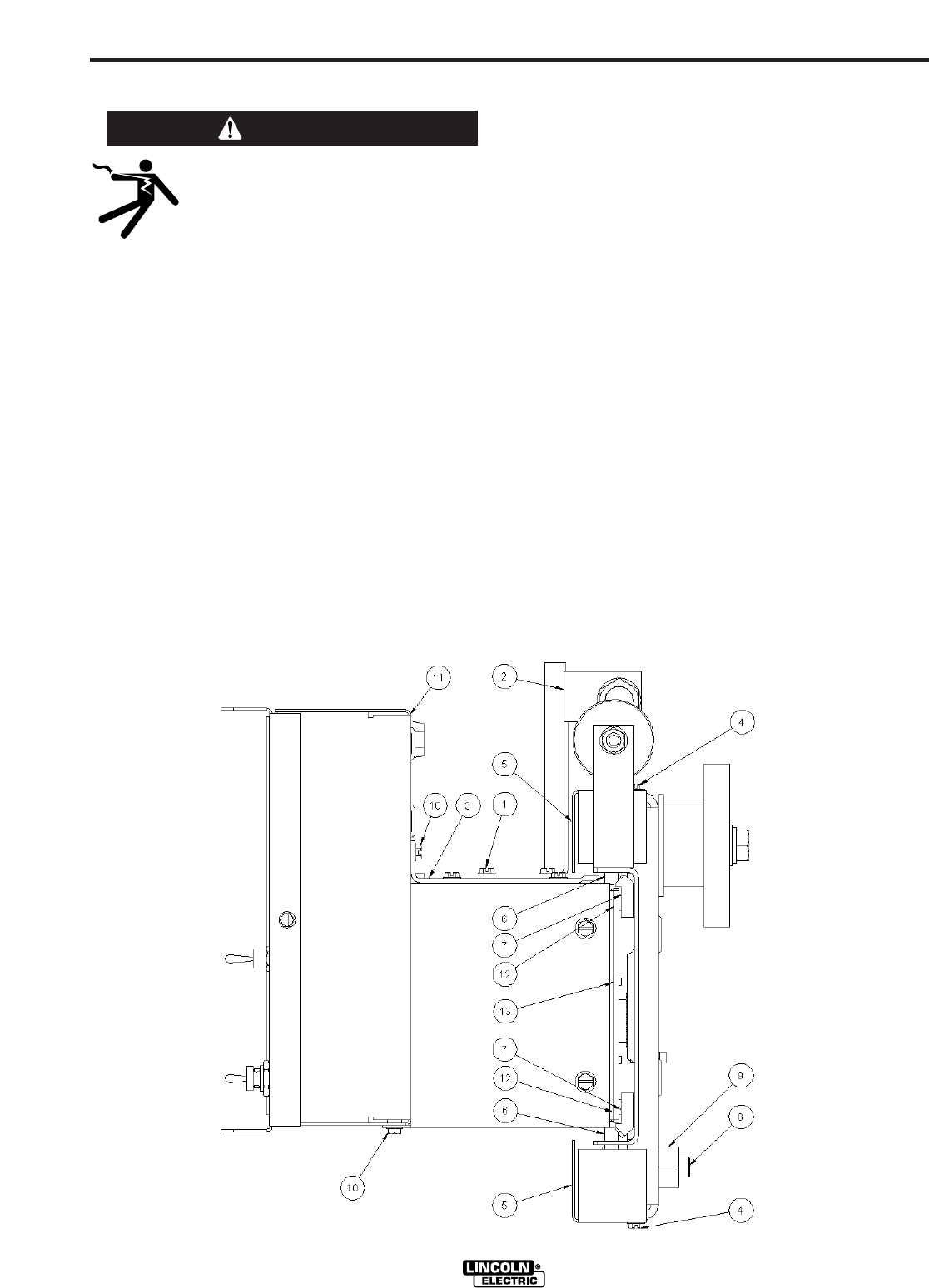

(See Figure D-1)

"V" Tracks and Bearings

Clean, inspect, and re-lubricate twice per year (more

often under severe duty applications) as follows:

1. Remove the four screws Item 1 holding the proximi-

ty sensor bracket Item 2 to the top cover Item 3.

2. Remove the four screws Item 4 holding the top and

bottom track covers Item 5 in place and remove the

track covers.

3. Clean the four "V" groove bearings Item 6 and the

top and bottom "V" tracks Item 7 and inspect for

wear.

4. Provided the tracks are not severely worn, re-lubri-

cate the contact surface of the bearings and tracks

with a graphite or moly filled grease such as auto-

motive chassis grease and re-assemble.

NOTE: Do not lubricate the gear motor pinion

and gear rack.

If the wear on the inside edge of the top rack has

reached 0.040", either interchange the top and bottom

tracks if the bottom track is not severely worn, or

replace both tracks.

To remove the tracks:

1. Loosen the 1/2-13 hex head screws Item 8 which

hold the bottom "V" bearings Item 6 in place by

rotating the screws while keeping the eccentric nuts

Item 9 from turning.

2. Rotate the eccentric nuts to give maximum clear-

ance of the bearings in relationship to the tracks.

3. Lift the carriage to disengage the pinion gear from

the rack and remove. Set aside.

4. Remove the four screws Item 10 holding the control

box Item 11 in place. Maintain support for the con-

trol box in order not to strain any leads.

FIGURE D-1