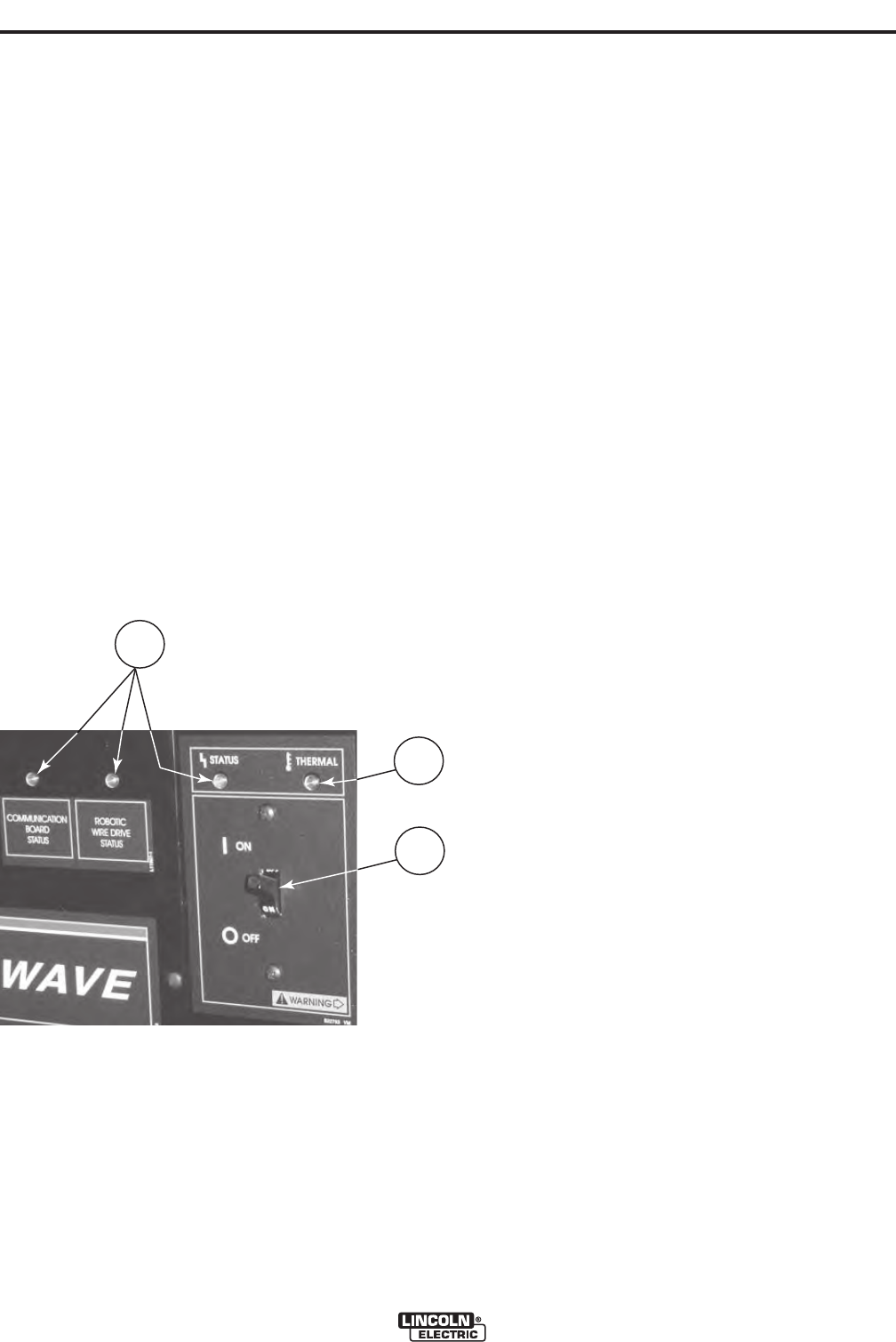

(See Figure B.5)

4. 10 Amp Wire Feeder Circuit Breaker: Protects 40

volt DC wire feeder power supply.

5. 115 VAC Auxiliary Power Circuit Breaker:

Protects case front receptacle auxiliary supply. (10

amps)

6. 21 Work Sense Lead Connector(4-Pin)

7. Arclink Connector (5-Pin)

8. DeviceNet Connector (5-Pin)

9. Work Output Studs

10. Electrode Output Studs

11. Auxiliary Output

12. Ethernet Connector (RJ-45)

13. Wire Feeder Connection (14-Pin)-Connects the

control cable between the power source and wire

feeder.

14. External Input Connector

15. Serial Communication (RS-232)

B-4

OPERATION

B-4

CASE FRONT CONTROL DESCRIPTIONS

(See Figure B.4)

1. Power Switch: Controls input power to the Power

Wave

2. Status Lights: A two color light that indicates sys-

tem errors. Normal operation is a steady green

light. Error conditions are indicated in the

Troubleshooting Section.

NOTE: The robotic PowerWaves’ status light will

flash green, for up to 15 seconds when the

machine is first turned on. This is a normal sit-

uation as the machine goes through a self

test at power up.

3. Thermal Fault Light : A yellow light that comes on

when an over temperature situation occurs. Output is

disabled until the machine cools down. When cool,

the light goes out and output is enabled.

FIGURE B.4

POWER WAVE® AC/DC 1000

2

3

1