$%')$#

,!#%'$((

For any electrodes the procedures should be kept

within the rating of the machine. For electrode infor-

mation see the appropriate Lincoln publication.

() $#()#)*''#),!#

Connect welding cables to the "TO WORK” and

"ELECTRODE” studs. Start the engine. The “RANGE”

switch markings indicate the maximum current for that

range as well as the typical electrode size for that

range. The “OUTPUT” Control provides fine adjust-

ment of the welding current within the select range.

For maximum output within a selected range set the

“OUTPUT” Control at 10. For minimum output within a

selected range set the “OUTPUT” Control at 5. (“OUT-

PUT” Control settings below 5 may reduce arc stabili-

ty) For best overall welding performance set the

“RANGE” Switch to the lowest setting and the OUT-

PUT” Control near the maximum to achieve the

desired welding current.

'#())# ).%! *''#)'#

!)'$(/

The RANGER® 225 can be used with a broad range

of DC stick electrodes. See “Welding Tips 1” included

with the RANGER® 225 for electrodes within the rat-

ing of this unit and recommended welding currents of

each.

(')()'))$#()#)*''#)

,!#

The RANGER® 225 can be used for Scratch-Start of DC TIG

welding applications. To initiate a weld, the course and fine out-

put control knobs must be set for the desired current. The tung-

sten electrode is then scratch on the work which establishes the

arc.

To stop the arc, simply lift the TIG torch away from the work

piece. The tungsten may then be scratched on the work piece

to restrike the arc.

If a high frequency start is desired, the K930-2 TIG Module can

be used with the RANGER® 225. The settings are referenced.

The RANGER® 225 and any high frequency generating equip-

ment must be properly grounded. See the K930-2 TIG Module

operating manuals for complete instructions on installation,

operation and maintenance.

When using the TIG Module, the OUTPUT control on

the

RANGER® 225 is used to set the maximum range of the

CURRENT CONTROL on the TIG Module or an Amptrol if con-

nected to the TIG Module.

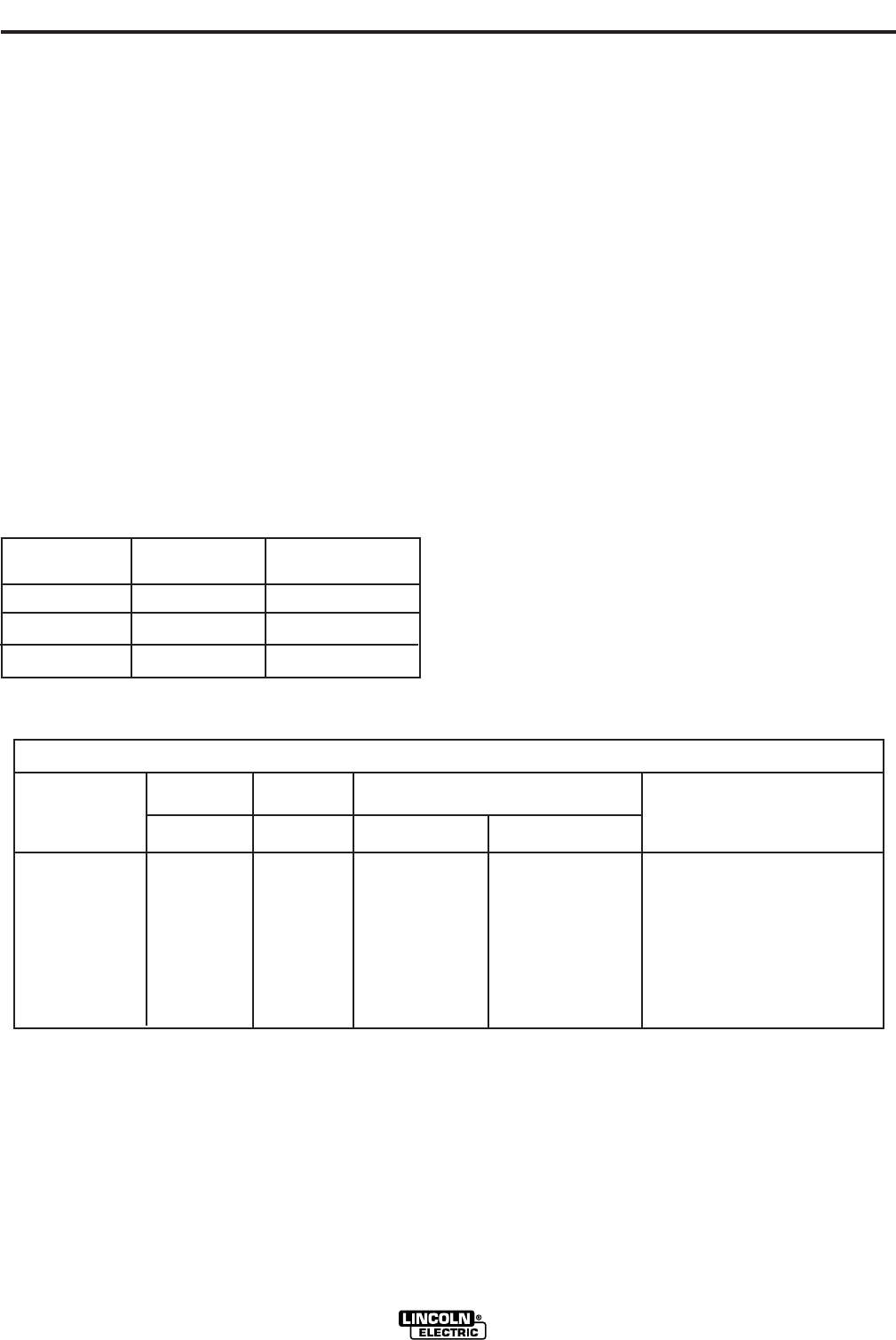

'#'Q

90 MAX.

145 MAX.

225 MAX.

3/32

1/8

5/32

40 TO 90 AMPS

70 TO 145 AMPS

120 TO 225 AMPS

).%!*''#)'#(

$')*#()#!)'$(

Tungsten Electrode DCEN (-) DCEP (+) Approximate Argon Gas Flow TIG TORCH

Diameter in. (mm) Flow Rate C.F.H. ( l /min.) Nozzle Size (4), (5)

1%, 2% Thoriated 1%, 2% Thoriated Aluminum Stainless Steel

Tungsten Tungsten

.010 (.25) 2-15 (3) 3-8 (2-4) 3-8 (2-4) #4, #5, #6

0.020 (.50) 5-20 (3) 5-10 (3-5) 5-10 (3-5)

0.040 (1.0) 15-80 (3) 5-10 (3-5) 5-10 (3-5)

1/16 (1.6) 70-150 10-20 5-10 (3-5) 9-13 (4-6) #5, #6

3/32 (2.4) 150-250 15-30 13-17 (6-8) 11-15 (5-7) #6, #7, #8

1/8 (3.2) 250-400 25-40 15-23 (7-11) 11-15 (5-7)

5/32 (4.0) 400-500 40-55 21-25 (10-12) 13-17 (6-8) #8, #10

3/16 (4.8) 500-750 55-80 23-27 (11-13) 18-22 (8-10)

1/4 (6.4) 750-1000 80-125 28-32 (13-15) 23-27 (11-13)

(1) When used with argon gas. The current ranges shown must be reduced when using argon/helium or pure helium shielding gases.

(2) Tungsten electrodes are classified as follows by the American Welding Society (AWS):

Pure EWP

1% Thoriated EWTh-1

2% Thoriated EWTh-2

Though not yet recognized by the AWS, Ceriated Tungsten is now widely accepted as a substitute for 2% Thoriated Tungsten in AC and DC applications.

(3) DCEP is not commonly used in these sizes.

(4) TIG torch nozzle "sizes" are in multiples of 1/16ths of an inch:

# 4 = 1/4 in. (6 mm)

# 5 = 5/16 in. (8 mm)

# 6 = 3/8 in. (10 mm)

# 7 = 7/16 in. (11 mm)

# 8 = _ in. (12.5 mm)

#10 = 5/8 in. (16 mm)

(5) TIG torch nozzles are typically made from alumina ceramic. Special applications may require lava nozzles, which are less prone to breakage, but cannot withstand high temperatures

and high duty cycles.