POWER MIG

®

255XT

www.lincolnelectric.com

[4]

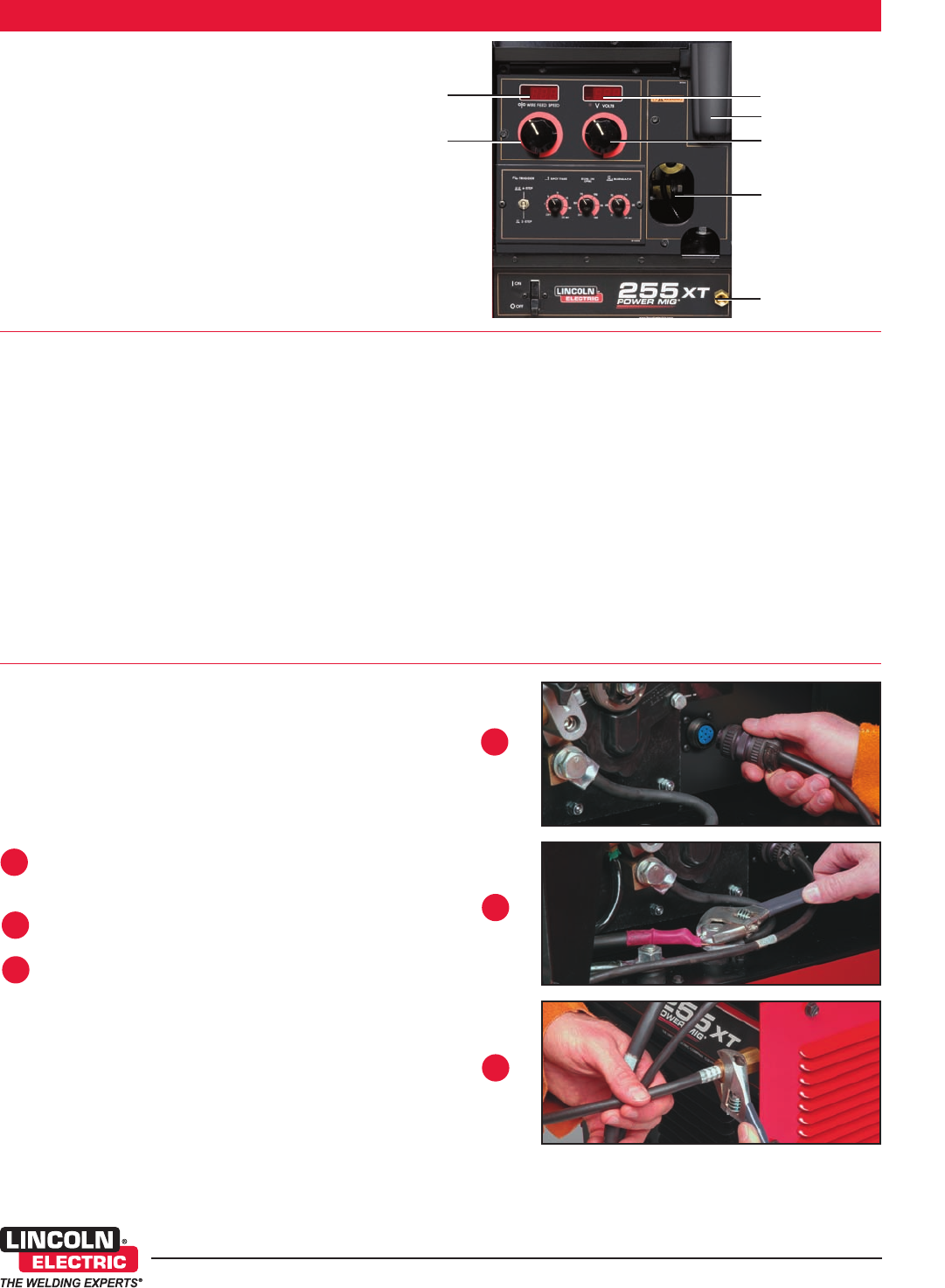

A CLOSER LOOK

SPOOL GUN READY!

The POWER MIG

®

255XT has built-in electronics to drive either a

Magnum

®

SG Spool Gun or a Magnum

®

250LX Spool Gun. In

addition, a second gas solenoid is provided to supply and control

gas flow to the spool gun.

Easy as 1-2-3!

Simply plug the spool gun control cable into the built-in 7-pin

connector (Magnum

®

SG gun requires K2445-1, 6- to 7-pin

control cable adapter plug.)

Connect the spool gun’s power cable to the output terminal

in the wire drive compartment.

Hook the spool gun gas line to the solenoid gas fitting and

you’re ready to weld!

QUALITY AND RELIABILITY

• Fan-As-Needed

™

(F.A.N.

™

) provides cooling of transformer and other components when welding,

reducing power consumption, noise and extending welder life.

• Thermostatic protection from current overload and excessive temperatures.

• Printed circuit boards are environmentally-shielded using Lincoln's engineered potting and protective

frame trays.

• Low input current draw for energy-efficient low cost operation.

• Power source line voltage regulation holds voltage setting constant to maintain weld quality even when

the input voltage fluctuates ±10%.

• Manufactured under a quality system certified to ISO 9001 requirements and ISO 14001 Environmental Standards.

• Approved by Canadian Standards Association (CSA).

• Three-year warranty on parts and labor (90 days warranty on gun).

Key Controls

A. Digital meter displays preset wire feed speed.

B. Presettable digital wire speed control with fine

resolution at low settings.

C. Digital meter displays preset voltage setting and

actual voltage while welding.

D. Built-in gun holder.

E. Presettable digital voltage control with fine resolution

at low settings.

F. Angled gun connection for improved feedability.

G. Second gas solenoid for spool gun use.

B

A

D

C

F

E

1

G

2

3

1

2

3