A-4

INSTALLATION

POWER WAVE 455M (CE)

A-4

CABLE INDUCTANCE, AND ITS AFFECT

ON PULSE WELDING

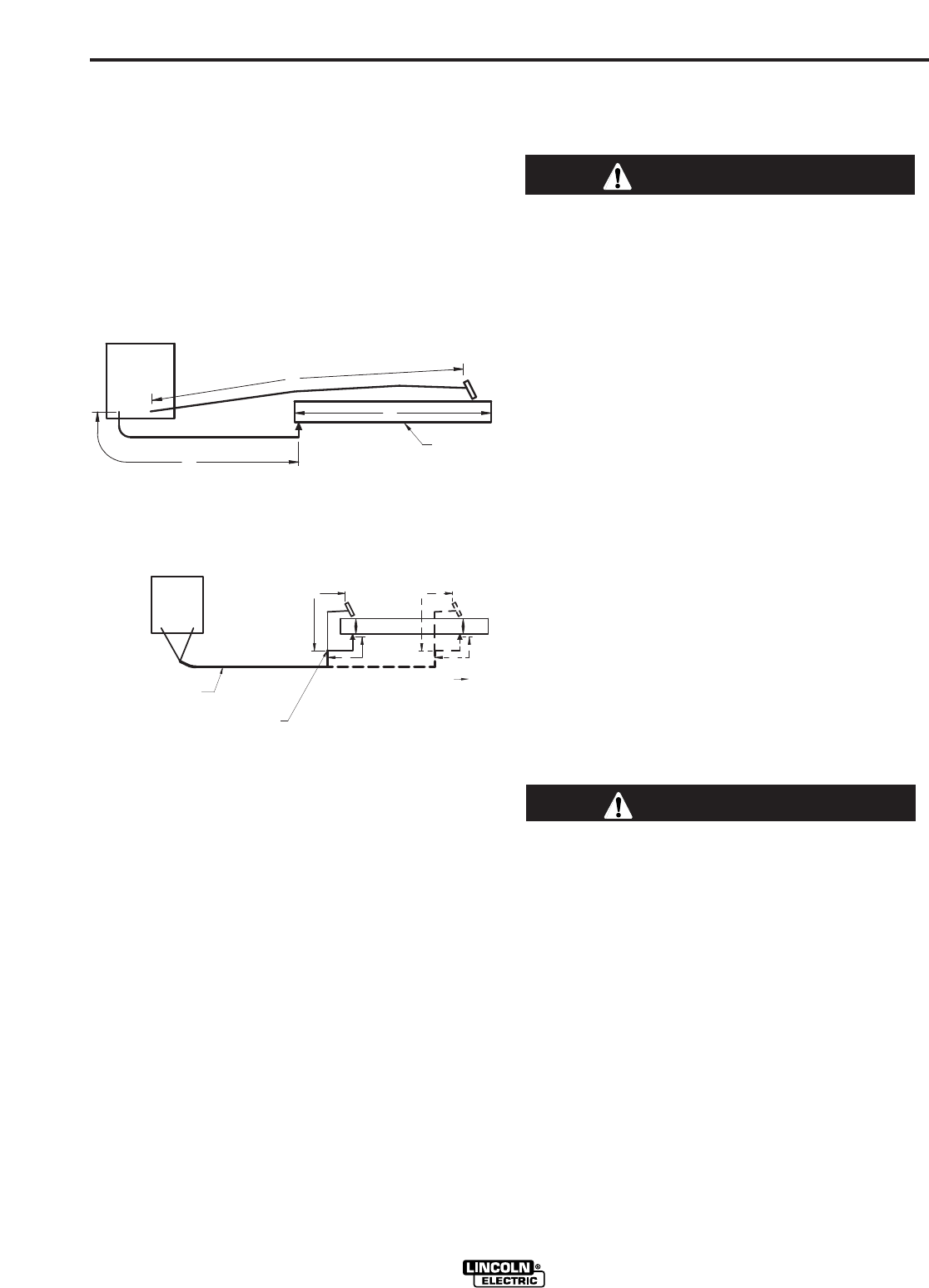

For Pulse Welding processes, cable inductance will

cause the welding performance to degrade. For the

total welding loop length less than 15.24m (50 ft.), tra-

ditional welding cables may be used without any

effects on welding performance. For the total welding

loop length greater than 15.24m (50 ft.), the K1796

Coaxial Welding Cables are recommended. The weld-

ing loop length is defined as the total of electrode

cable length (A) + work cable length (B) + work length

(C) (See Figure A.3).

For long work piece lengths, a sliding ground should

be considered to keep the total welding loop length

less than 15.24m (50 ft.). (See Figure A.4.)

Output connections on some Power Waves are made

via 1/2-13 threaded output studs located beneath the

spring loaded output cover at the bottom of the case

front.

Most welding applications run with the electrode being

positive (+). For those applications, connect the elec-

trode cable between the wire feeder and the positive

(+) output stud on the power source (located beneath

the spring loaded output cover near the bottom of the

case front). Connect the other end of the electrode

cable to the wire drive feed plate. The electrode cable

lug must be against the feed plate. Be sure the con-

nection to the feed plate makes tight metal-to-metal

electrical contact. The electrode cable should be sized

according to the specifications given in the work cable

connections section. Connect a work lead from the

negative (-) power source output stud to the work

piece. The work piece connection must be firm and

secure, especially if pulse welding is planned.

For additional Safety information regarding the elec-

trode and work cable set-up, See the standard "SAFE-

TY INFORMATION" located in the front of the

Instruction Manuals.

Excessive voltage drops caused by poor work

piece connections often result in unsatisfactory

welding performance.

------------------------------------------------------------------------

NEGATIVE ELECTRODE POLARITY

When negative electrode polarity is required, such as

in some Innershield applications, switch the output

connections at the power source (electrode cable to

the negative (-) stud, and work cable to the positive (+)

stud).

When operating with electrode polarity negative the

"Electrode Sense Polarity" DIP switch must be set to

the "Negative" position on the Wire Drive Feed Head

PC Board. The default setting of the switch is positive

electrode polarity. Consult the Power Feed instruction

manual for further details.

VOLTAGE SENSING

The best arc performance occurs when the Power

Waves have accurate data about the arc conditions.

Depending upon the process, inductance within the

electrode and work lead cables can influence the

apparent voltage at the studs of the welder. Voltage

sense leads improve the accuracy of the arc conditions

and can have a dramatic effect on performance.

Sense Lead Kits (K940-10, -25 or -50) are available for

this purpose.

If the voltage sensing is enabled but the sense

leads are missing, improperly connected, or if the

electrode polarity switch is improperly configured,

extremely high welding outputs may occur.

------------------------------------------------------------------------

The ELECTRODE sense lead (67) is built into the con-

trol cable, and is automatically enabled for all semi-

automatic processes. The WORK sense lead (21) con-

nects to the Power Wave 455M (CE) at the four pin

connector located underneath the output stud cover.

By default the WORK voltage is monitored at the out-

put stud in the Power Wave 455M (CE). For more

information on the WORK sense lead (21), see "Work

Voltage Sensing” in the following paragraph.

All constant current processes sense the voltage at the

output studs of the Power Wave 455M (CE) by default.

CAUTION

CAUTION

B

A

C

FIGURE A.3

POWER

WAVE

WORK

A

C

B

POWER

WAVE

FIGURE A.4

K1796 COAXIAL CABLE

MEASURE FROM END

OF OUTER JACKET OF

CABLE

C

A

B

WORK

SLIDING WORK CONNECTION

FIGURE A.4