PROCEDURE RECOMMENDATIONS

When properly used, plasma arc cutting is a very eco-

nomical process. Improper use will result in a very

high operating cost.

General - In All Cases

• Follow safety precautions as printed throughout this

operating manual and on the machine.

• If piercing is required, slowly lower the torch at an

angle of about 30° to blow the dross away from

the torch tip and slowly rotate the torch to a ver-

tical position as the arc becomes deeper. This

process will blow a lot of molten metal and

dross. Be careful! Blow the dross away from

the torch, the operator and any flammable

objects.

• The nozzle should not be dragged on the metal

surface. A drag spacer is provided to maintain a

consistant touch height. Refer to Touch Parts

Configurations in this Section.

• Where possible, start the cut from the edge of the

work piece.

• Keep moving! A steady speed is necessary. Do

not pause.

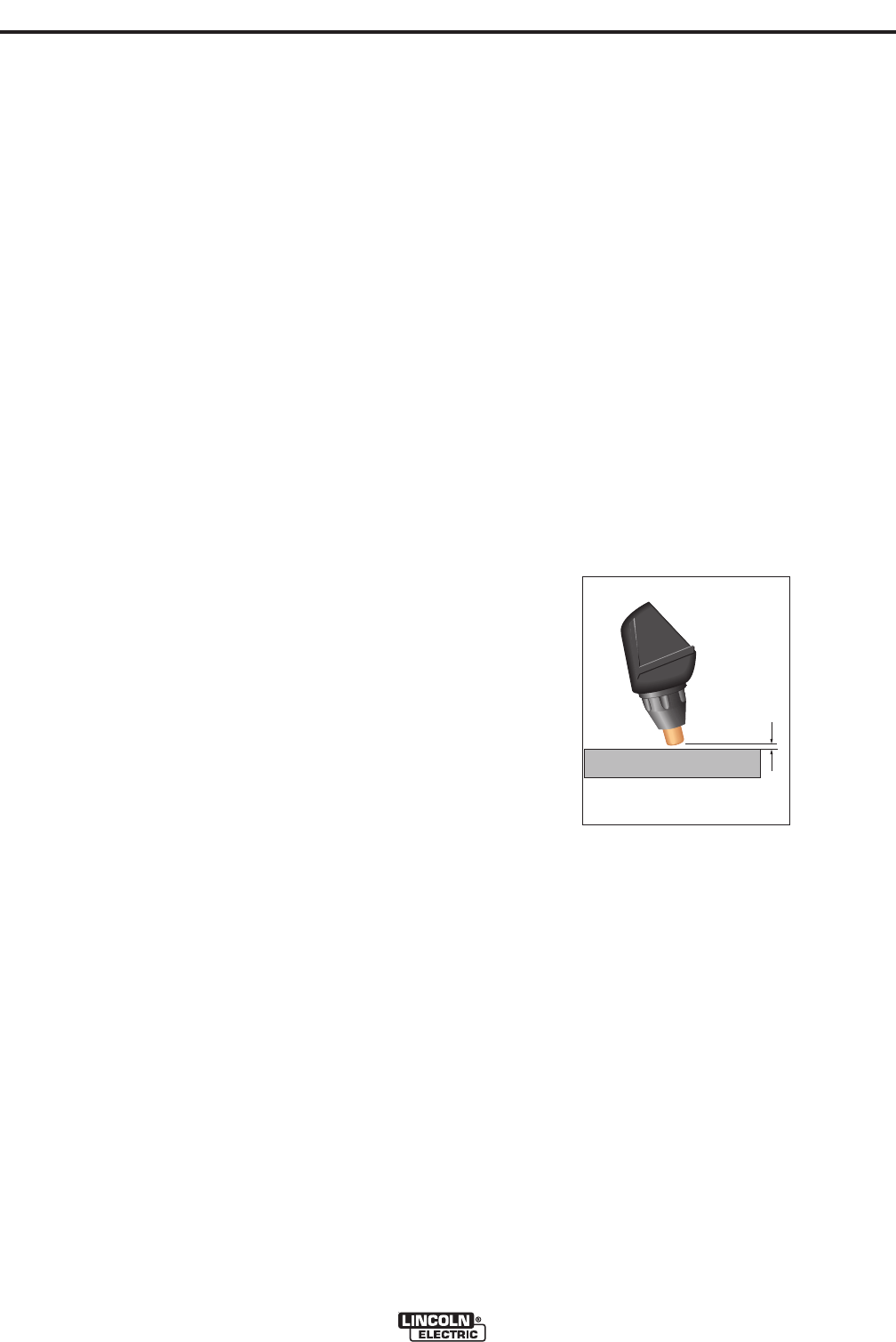

Torch Standoff

DRAG thru 1/16"

Standoff

Output Setting

Min. thru Mid. Range

Machine Output Setting

Torch Standoff

DRAG thru 1/16"

Standoff

Output Setting

Min. thru Mid. Range

Machine Output Setting

1/16” Standoff

B-7

OPERATION

B-7

• Replace the nozzle when the orifice exit is eroded

away or oval shaped.

• After the problem is found, or if there is nothing

apparently wrong, reset the machine by turning the

power switch OFF and then ON again. (It is possi-

ble for electrical noise to trip the safety circuit on

rare occasions. This should not be a regular occur-

rence.)

• If the machine does not reset or continues to trip,

consult the Troubleshooting Section.

• Use the proper cutting procedures referred to in

Procedure Recommendations.

PILOT ARC DISCUSSION

The TOMAHAWK™ 625 has a smooth, continuous

pilot arc. The pilot arc is only a means of transferring

the arc to the workpiece for cutting. Repeated pilot arc

starts, in rapid succession, is not recommended as

these starts will generally reduce consumable life.

Occasionally, the pilot arc may sputter or start inter-

mittently. This is aggravated when the consumables

are worn or the air pressure is too high. Always keep

in mind that the pilot arc is designed to transfer the arc

to the workpiece and not for numerous starts without

cutting.

The TOMAHAWK™ 625 does not utilize high frequen-

cy starting. When the pilot arc is started, a slight

impulse will be felt in the torch handle. This occur-

rence is normal and is the mechanism which starts the

plasma arc. This impulse can also be used to help

troubleshoot a "no start" condition.

TOMAHAWK™ 625