PARALLELING

When paralleling machines in order to combine their

outputs, all units must be operated in the CC-STICK

mode only at the same output settings. To achieve

this, turn the WELD MODE switch to the CC-STICK

position. Operation in other modes may produce errat-

ic outputs, and large output imbalances between the

units.

AUXILIARY POWER OPERATION

Start the engine and set the IDLER control switch to

the desired operating mode. Full power is available

regardless of the welding control settings, if no weld-

ing current is being drawn.

The auxiliary power of the AIR VANTAGE® 500 con-

sists of two 15Amp 240VAC single phase receptacles.

The auxiliary power receptacles should only be used

with three wire grounded type plugs or approved dou-

ble insulated tools with two wire plugs.

The current rating of any plug used with the system

must be at least equal to the current capacity of the

associated receptacle.

SIMULTANEOUS WELDING AND AUXIL-

IARY POWER LOADS

It must be noted that the above auxiliary power ratings

are with no welding load.

Simultaneous welding and power loads are specified

in table B.4.

AIR VANTAGE® 500 CUMMINS Extension Cord Length Recommendations

(Use the shortest length extension cord possible sized per the following table.)

AIR VANTAGE® 500 CUMMINS

B-10

OPERATION

B-10

TABLE B.5

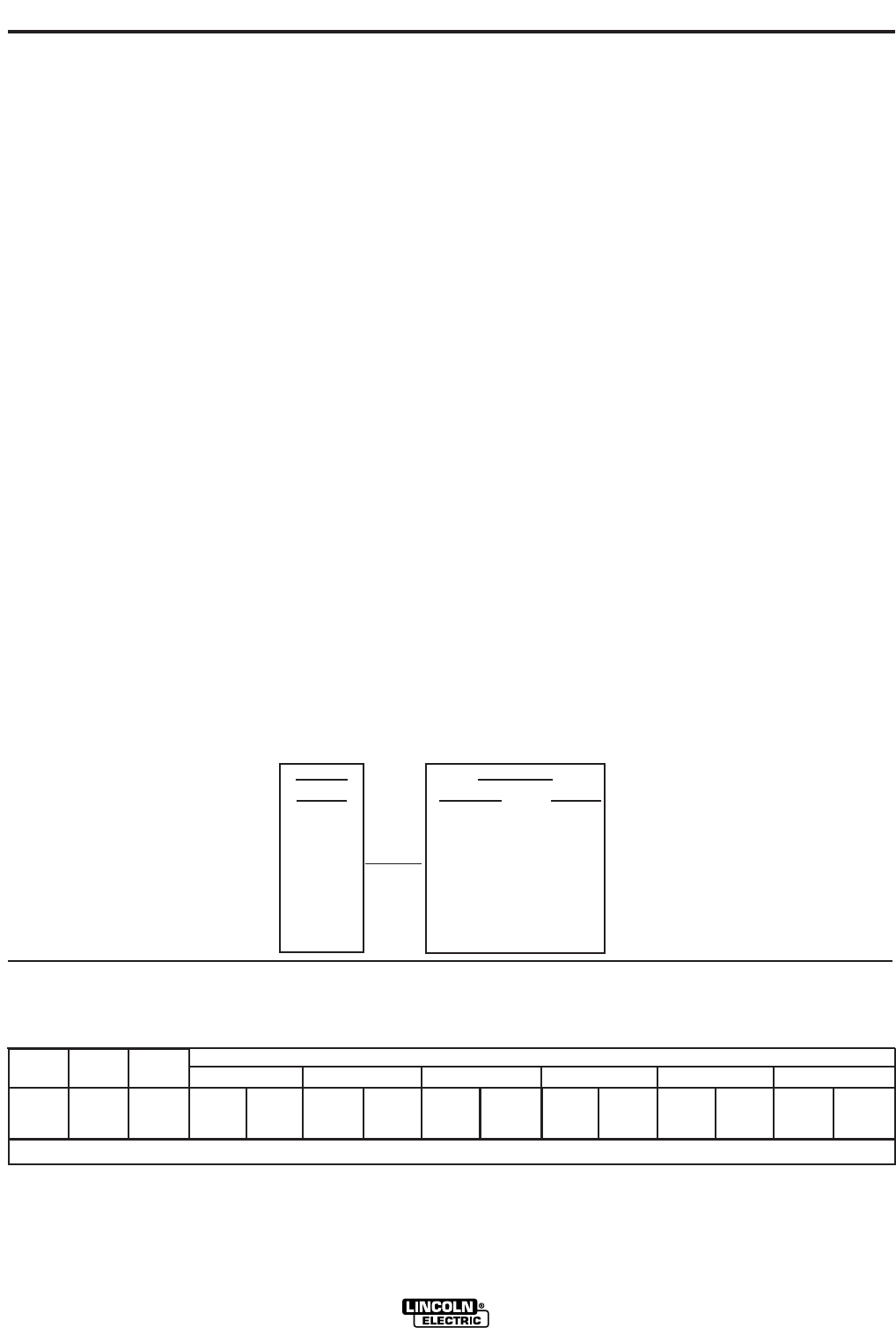

TABLE B.4 AIR VANTAGE® 500 SIMULTANEOUS WELDING AND POWER LOADS

WELD

AMPS

0

100

200

250

300

400

500

1 PHASE

WATTS AMPS

7,200 30

7,200 30

7,200 30

7,200 30

7,200 30

5,600 23

0 0

PLUS

Maximum Allowable Cord Length in ft. (m) for Conductor Size

Conductor size is based on maximum 2.0% voltage drop.

14AWG 2.5

2

mm 12AWG 4.0

2

mm 10AWG 6.0

2

mm 8AWG 10.0

2

mm 6AWG 16.0

2

mm 4AWG 25.0

2

mm

Load

(Watts)

3600

Current

(Amps)

15

Voltage

(Volts)

240

60

(18)

75 (23) 150

46 225

(69) 350 107

600 (183)