A-2

INSTALLATION

VANTAGE® 580

A-2

SAFETY PRECAUTIONS

Only qualified personnel should install,

use, or service this equipment.

Do not attempt to use this equipment until you

have thoroughly read the engine manufacturerʼs

manual supplied with your welder. It includes

important safety precautions, detailed engine

starting, operating and maintenance instructions,

and parts lists.

------------------------------------------------------------------------

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or

electrode with skin or wet clothing.

• Insulate yourself from work and

ground

• Always wear dry insulating gloves.

------------------------------------------------------------------------

ENGINE EXHAUST can kill.

• Use in open, well ventilated areas or

vent exhaust outside.

------------------------------------------------------------------------

MOVING PARTS can injure.

• Do not operate with doors open or

guards off.

• Stop engine before servicing.

• Keep away from moving parts.

------------------------------------------------------------------------

See additional warning information at

front of this operatorʼs manual.

WARNING

VRD (VOLTAGE REDUCTION DEVICE)

The VRD reduces the OCV (Open Circuit Voltage) at the

welding output terminals while not welding to less than 20V

DC when the resistance of the output circuit is above 200Ω

(ohms).

This feature provides additional safety in environments

with a higher risk of electric shock such as wet areas and

hot humid sweaty conditions.

When VRD is “On” the DOWNHILL PIPE mode is not

available.

The VRD requires that the welding cable connections be

kept in good electrical condition because poor connections

will contribute to poor starting. Having good electrical con-

nections also limits the possibility of other safety issues

such as heat-generated damage, burns and fires.

The machine is shipped with the VRD switch in the “On”

position. To turn it “On” or “Off”.

• Turn the engine “Off”.

• Disconnect the negative battery cable.

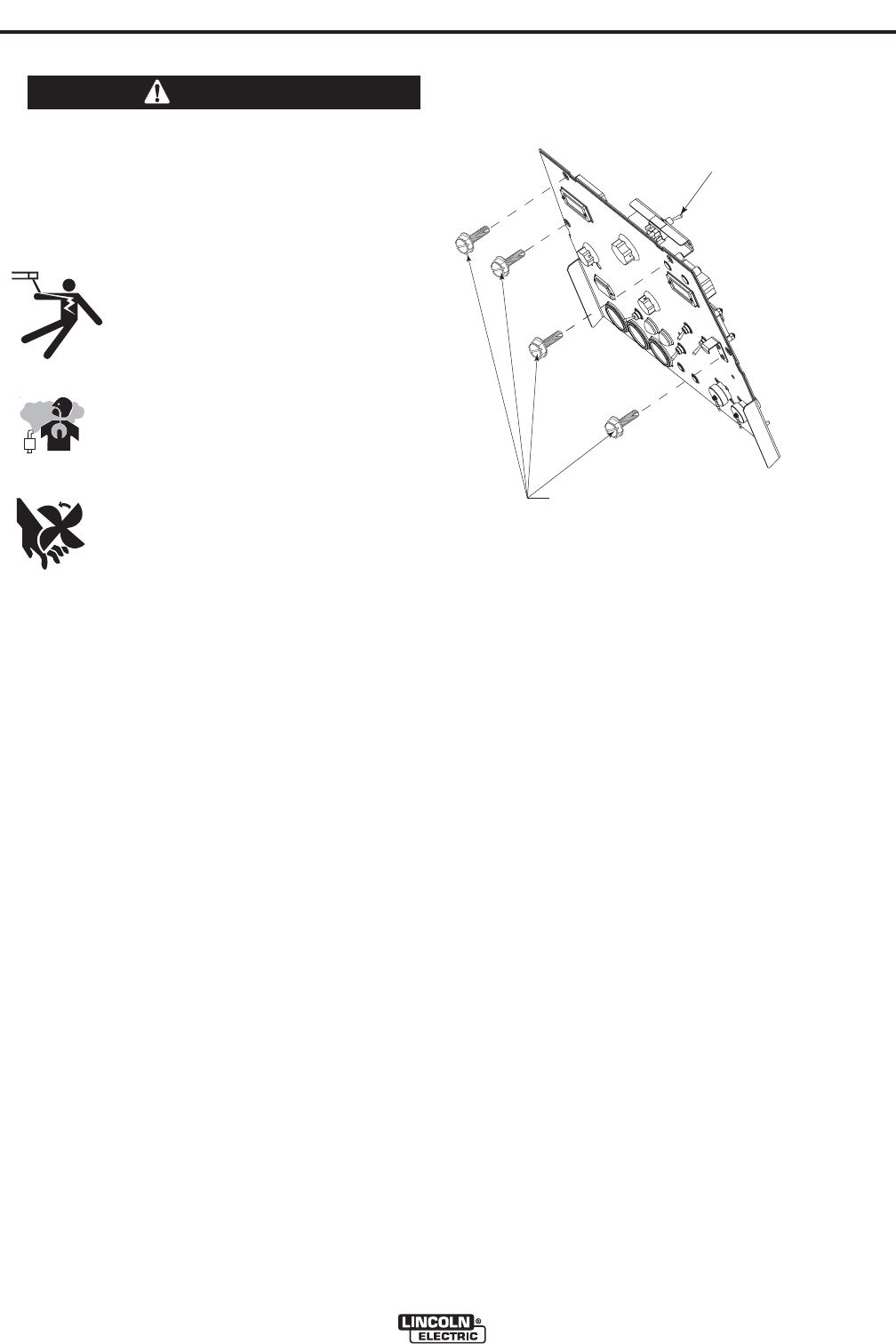

• Lower the control panel by removing 4 front

panel screws.

(See Figure A.1)

• Place the VRD switch in the “On” or “Off” position.

(See Figure A.1)

LOCATION AND VENTILATION

The welder should be located to provide an unrestrict-

ed flow of clean, cool air to the cooling air inlets and to

avoid restricting the cooling air outlets. Also, locate

the welder so that the engine exhaust fumes are prop-

erly vented to an outside area.

STACKING

VANTAGE® 580 machines cannot be stacked.

ANGLE OF OPERATION

Engines are designed to run in the level condition

which is where the optimum performance is achieved.

The maximum angle of continuous operation is 25

degrees in all directions, 35 degrees Intermittent (less

than 10 minutes continuous) in all directions. If the

engine is to be operated at an angle, provisions must

be made for checking and maintaining the oil level at

the normal (FULL) oil capacity in the crankcase.

When operating the welder at an angle, the effective

fuel capacity will be slightly less than the amount

specified.

LIFTING

The VANTAGE® 580 weighs approximately 1460lbs.

(662kg.) with a full tank of fuel 1290lbs. (586kg) less

fuel. A lift bail is mounted to the machine and should

always be used when lifting the machine.

(VRD)-VOLTAGE REDUCTION DEVICE

SWITCH IS LOCATED IN THIS AREA.

REMOVE 4 FRONT PANEL

SCREWS TO ACCESS

(VRD) SWITCH

FIGURE A.1

With the VRD switch in the “On” position, the VRD lights

are enabled.