AUXILIARY POWER:

Start the engine and set the IDLER control switch to

the desired operating mode. Full power is available

regardless of the welding control settings providing no

welding current is being drawn.

Simultaneous Welding and Auxiliary Power Loads

The auxiliary power ratings are with no welding load.

Simultaneous welding and power loads are specified

in Table B.5.

VANTAGE® 580

B-7

OPERATION

B-7

This will keep the "Solid State" contactor open and provide a

"cold" electrode until the Amptrol or Arc Start Switch is pressed.

When using the TIG Module, the OUTPUT CONTROL on the

VANTAGE® 580 is used to set the maximum range of the CUR-

RENT CONTROL on the TIG Module or an Amptrol if connect-

ed to the TIG Module.

NOTE: The TIG process is to receive a low voltage welding

process. There is no difference in operation with the

VRD “On” or “Off” for this mode. For indicator light oper-

ation, see

Table B.1

.

WIRE WELDING-CV

Connect a wire feeder to the VANTAGE® 580 according to the

instructions in INSTALLATION INSTRUCTIONS Section.

The VANTAGE® 580 in the CV-WIRE mode, permits it to be

used with a broad range of flux cored wire (Innershield and

Outershield) electrodes and solid wires for MIG welding (gas

metal arc welding). Welding can be finely tuned using the ARC

CONTROL. Turning the ARC CONTROL clockwise from –10

(soft) to +10 (crisp) changes the arc from soft and washed-in to

crisp and narrow. It acts as an inductance/pinch control. The

proper setting depends on the procedure and operator prefer-

ence. Start with the dial set at 0.

ARC GOUGING

The VANTAGE® 580 can be used for arc gouging. For

optimal performance, set the MODE per TABLE B.4.

Set the OUTPUT CONTROL knob to adjust output

current to the desired level for the gouging electrode

being used according to the ratings in the following

Table B.4.

TABLE B.4

The ARC CONTROL is not active in the ARC GOUG-

ING Mode. The ARC CONTROL is automatically set

to maximum when the ARC GOUGING mode is

selected which provides the best ARC GOUGING per-

formance.

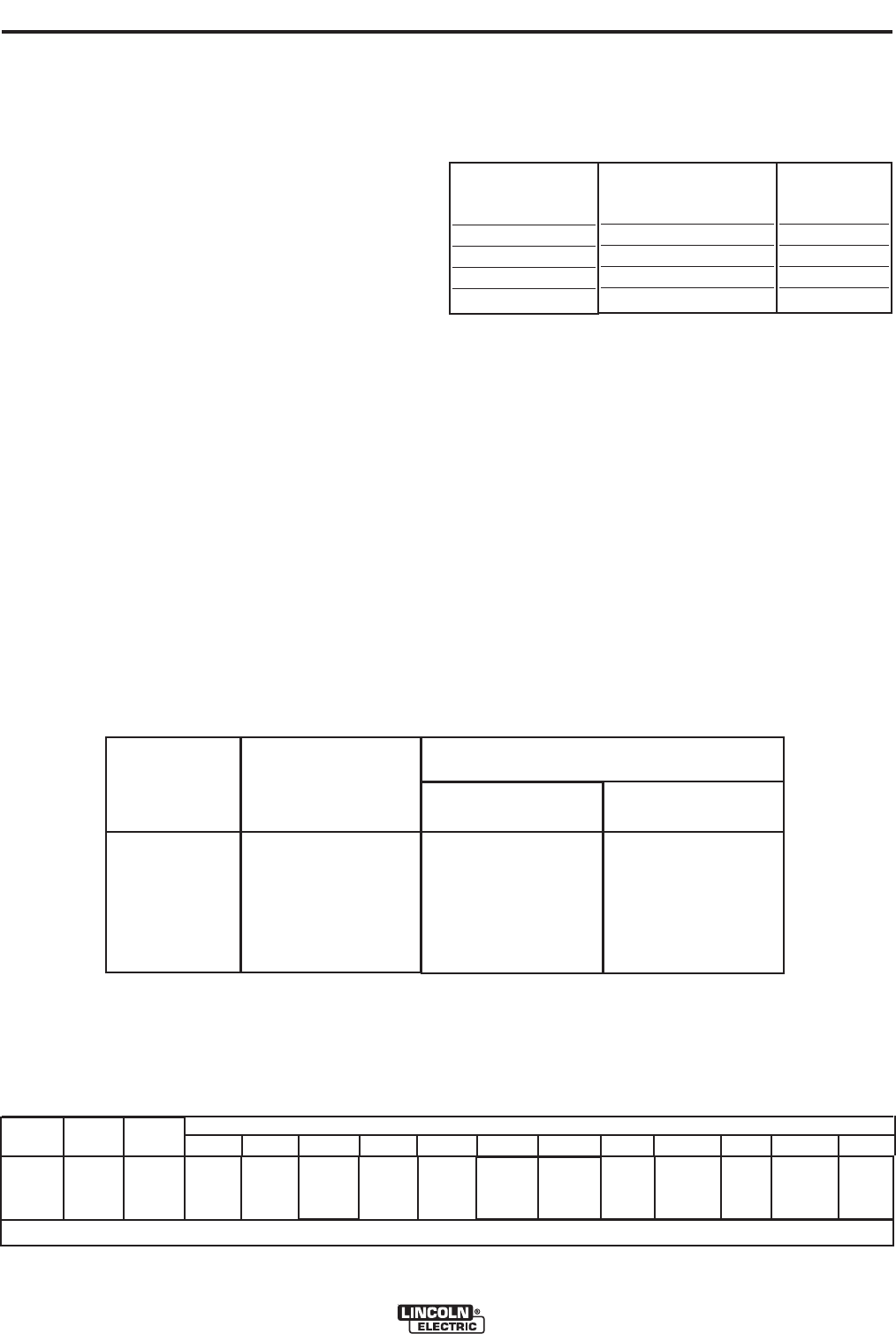

TABLE B.5 VANTAGE® 580 PERKINS SIMULTANEOUS WELDING AND POWER LOADS

WELDING

OUTPUT

500A/40V

350A/34V

200A/30V

150A/26V

90A/24V

0

PERMISSIBLE

POWER-WATTS

(Unity Power Factor)

0

8,100

12,000

16,000

18,000

20,000

@ 240V ±10%*

0

30*

30*

30*

30*

30*

@ 415V ±10%

0

14 amp/phase

18.5 amp/phase

23.6 amp/phase

26.4 amp/phase

28 amp/phase

Permissible Auxiliary

Current in Amperes

* Each receptacle is limited to 15 amps.

VANTAGE® 580 PERKINS Extension Cord Length Recommendations

(Use the shortest length extension cord possible sized per the following table.)

TABLE B.6

Maximum Allowable Cord Length in m (ft.) for Conductor Size

Conductor size is based on maximum 2.0% voltage drop.

2.5

2

mm 14AWG 4.0

2

mm 12AWG 6.0

2

mm 10AWG 10.0

2

mm 8AWG 16.0

2

mm 6AWG 25.0

2

mm 4AWG

Load

(Watts)

3,600

Current

(Amps)

15

Voltage

(Volts)

240

18

(60)

23 (75) 46

(150) 69

(225)

107

(350)

183 (600)

Carbon Diameter

1/8"(3.2mm)

5/32"(4.0mm)

3/16"9(4.8mm)

1/4"(6.4mm)

3/8"(10.0mm)

Current Range (DC,

electrode positive)

60-90 Amps

90-150 Amps

200-250 Amps

300-400 Amps

400-Max.Amps

Mode

CC-STICK

CC-STICK

ARC GOUGE

ARC GOUGE

ARC GOUGE