B-3

OPERATION

B-3

4. ARC CONTROL- The ARC CONTROL dial is active in

the CV-WIRE, CC-STICK and DOWNHILL PIPE modes, and

has different functions in these modes. This control is not

active in the TIG and ARC GOUGING mode.

CC-STICK mode: In this mode, the ARC CONTROL dial sets

the short circuit current (arc-force) during stick welding to

adjust for a soft or crisp arc. Increasing the dial from –10

(soft) to +10 (crisp) increases the short circuit current and

prevents sticking of the electrode to the plate while welding.

This can also increase spatter. It is recommended that the

ARC CONTROL be set to the minimum number without elec-

trode sticking. Start with a setting at 0.

DOWNHILL PIPE mode: In this mode, the ARC CONTROL

dial sets the short circuit current (arc-force) during stick weld-

ing to adjust for a soft or a more forceful digging arc (crisp).

Increasing the number from –10 (soft) to +10 (crisp) increases

the short circuit current which results in a more forceful dig-

ging arc. Typically a forceful digging arc is preferred for root

and hot passes. A softer arc is preferred for fill and cap pass-

es where weld puddle control and deposition ("stacking" of

iron) are key to fast travel speeds. It is recommended that the

ARC CONTROL be set initially at 0.

CV-WIRE mode: In this mode, turning the ARC CONTROL

clock wise from –10 (soft) to +10 (crisp) changes the arc from

soft and washed-in to crisp and narrow. It acts as an induc-

tance/pinch control. The proper setting depends on the proce-

dure and operator preference. Start with a setting of 0.

5. WELD OUTPUT TERMINALS WITH FLANGE

NUT- Provides a connection point for the electrode and

work cables.

6. GROUND STUD- Provides a connection point for

connecting the machine case to earth ground.

7. 14-PIN CONNECTOR- For attaching wire feeder control

cables. Includes contactor closure circuit, auto-sensing

remote control circuit, and 42V power. The remote control

circuit operates the same as the 6 Pin Amphenol.

8. 42V / 115V WIRE FEEDER VOLTAGE SWITCH:

Toggles output of 14-pin connector to voltage requirement

of Wire Feeder. (Located above 14-pin connector.)

9. 6-PIN CONNECTOR- For attaching optional remote con-

trol equipment. Includes auto-sensing remote control circuit.

10. WELD TERMINALS CONTROL SWITCH- In the

WELD TERMINALS ON position, the output is electrically

hot all the time.

In the REMOTELY CONTROLLED position, the output is

controlled by a wire feeder or amptrol device, and is electri-

cally off until a remote switch is depressed.

11. WIRE FEEDER VOLTMETER SWITCH:

Matches the polarity of the wire feeder voltmeter to the

polarity of the electrode.

12. VRD (Voltage Reduction Device) INDICATOR

LIGHTS- On the front panel of the VANTAGE® 580 are

two indicator lights. A red light when lit indicates OCV(Open

Circuit Voltage) is equal to or

greater than 30V and a green

light when lit indicates OCV(Open Circuit Voltage) is less

than 30V.

The VRD “On/Off” switch inside the control panel must be

“On” for the VRD function to be active and the lights to be

enabled. When the machine is first started with VRD

enabled, both lights will illuminate for 5 seconds.

These lights monitor the

OCV(Open Circuit Voltage) and weld

voltage at all times. In the CC-Stick mode when not welding

the green light will illuminate indicating that the VRD has

reduced the OCV to less than 30V. During welding the red

light will illuminate whenever the arc voltage is equal to or

greater than 30V. This means that the red and green light

may alternate depending on the weld voltage. This is normal

operation.

If the red light remains illuminated when not welding in the

CC-stick mode, the VRD is not functioning properly. Please

refer to your local field service shop for service.

If the VRD is turned “On” and the lights donʼt come “On”,

refer to the trouble shooting section.

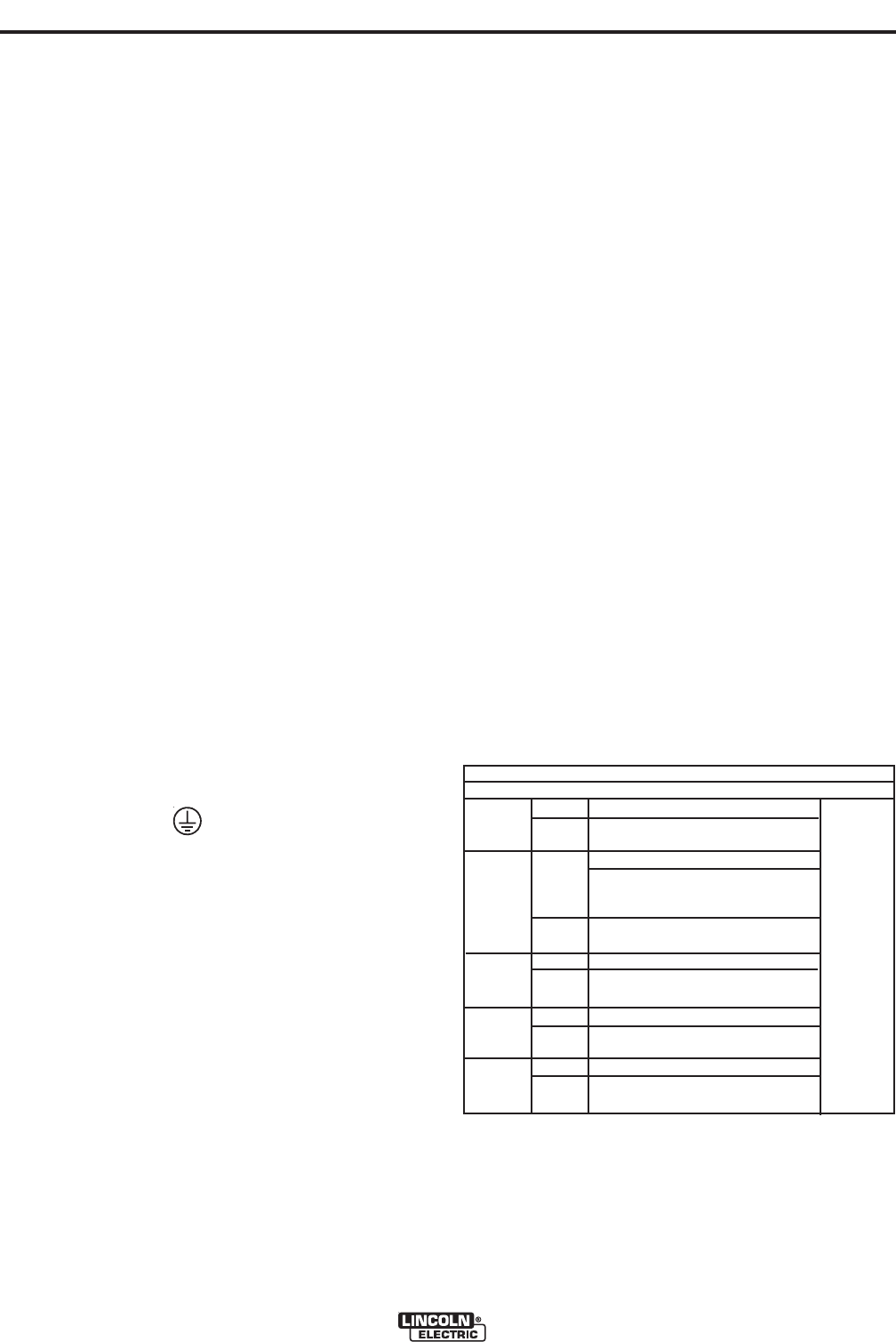

TABLE B.1

VRD INDICATOR LIGHTS

MODE VRD "ON" VRD "OFF"

CC-STICK OCV Green (OCV Reduced)

While Red or Green

Welding (Depends on Weld Voltage) *

CV-WIRE OCV Green (OCV Reduced)

Green (No OCV)

Weld Terminals Remotely Controlled

Gun Trigger Open No Lights

While Red or Green

Welding (Depends on Weld Voltage) *

PIPE OCV Green (No Output)

While Not Applicable (No Output)

Welding

ARC GOUGING

OCV Green (OCV Reduced)

While (Depends on Weld Voltage) *

Welding

TIG OCV Green (Process is Low Voltage)

While Green (Process is Low Voltage)

Welding

* It is normal for the lights to alternate between colors while welding.

VANTAGE® 580